Asphalt Reinforcement Geogrids for Roadbed Strengthening

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

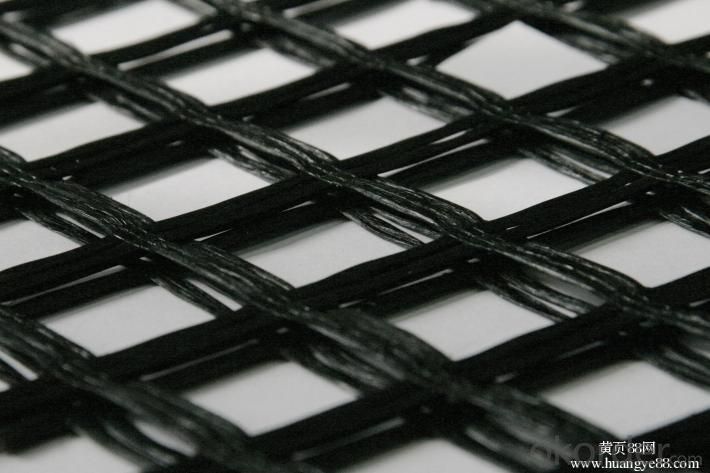

Structure of Fiberglass Geogrid

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance

Main Features of the Fiberglass Geogrid

Reinforcement fiberglss geogrid

made of fiberglass,glassfiber

fiber glass mesh

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Fiberglass Images

Fiberglass Geogrid Specification

Property | Test Method | TGSB 30-30 | TGSB 40-40 | TGSB 50-50 | TGSB 60-60 | |

Ultimate tensile strength(1) (kN/m) | MD |

EN ISO 10139

| 30 | 40 | 50 | 60 |

CD | 30 | 40 | 50 | 60 | ||

Elongation at maximum load (%) | MD | 3 | ||||

CD | 3 | |||||

Approximate mesh size(mm) | 12.7×12.7 25.4×25.4 40×40 | |||||

Roll Width (m) | 1-6 | |||||

Roll Length(m) | 50-200 | |||||

Property | Test Method | TGSB 60-60 | TGSB 70-70 | TGSB 80-80 | TGSB 90-90 | |

Ultimate tensile strength(1) (kN/m) | MD |

EN ISO 10139

| 60 | 70 | 80 | 90 |

CD | 60 | 70 | 80 | 90 | ||

Elongation at maximum load (%) | MD | 3 | ||||

CD | 3 | |||||

Approximate mesh size(mm) | 12.7×12.7 25.4×25.4 40×40 | |||||

Roll Width (m) | 1-6 | |||||

Roll Length(m) | 50-200 | |||||

Property | Test Method | TGSB 100-100 | TGSB 120-120 | TGSB 130-130 | TGSB 150-150 | |

Ultimate tensile strength(1) (kN/m) | MD |

EN ISO 10139

| 100 | 120 | 130 | 150 |

CD | 100 | 120 | 130 | 150 | ||

Elongation at maximum load (%) | MD | 13 | ||||

CD | 13 | |||||

Approximate mesh size(mm) | 12.7×12.7 25.4×25.4 40×40 | |||||

Roll Width (m) | 1-6 | |||||

Roll Length(m) | 50-200 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in temporary construction access roads for wetlands?

- Yes, geogrids can be used in temporary construction access roads for wetlands. Geogrids are commonly used in road construction to reinforce and stabilize the soil, especially in areas with poor ground conditions. They can help distribute loads, prevent soil erosion, and provide a stable surface for heavy machinery and vehicles. In the case of temporary construction access roads for wetlands, geogrids can be an effective solution to minimize environmental impact and protect the delicate ecosystem while providing safe access for construction activities.

- Q: PVC HF what is the material PVCHF bidirectional geogrid is like?

- Polyvinylchloride, PVC: polymer with random configuration of repeating units

- Q: Can geogrids be used in retaining walls?

- Yes, geogrids can be used in retaining walls. Geogrids are commonly used in retaining wall construction to provide additional stability and reinforcement to the structure. These geosynthetic materials are designed to improve the overall strength and performance of the retaining wall by distributing the forces exerted on it and preventing soil movement.

- Q: How is the installation of geogrids carried out?

- The installation of geogrids typically involves preparing the subgrade by removing any loose soil or debris, compacting the surface, and then laying the geogrid on top. The geogrid is then secured in place using stakes or anchors, and additional layers of soil or aggregate are placed on top to cover the geogrid. This helps to reinforce the soil, increase its stability, and prevent erosion or soil movement.

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by increasing the stability and load-bearing capacity of the soil, which reduces the need for excessive excavation and use of materials. This leads to a more efficient construction process, minimizing carbon emissions associated with transportation and energy consumption. Additionally, geogrids can enhance the lifespan of structures, reducing the need for frequent repairs or replacements that would otherwise generate additional carbon emissions.

- Q: Panzhihua steel plastic composite geogrid manufacturers, how much money, where to sell

- But in the actual project, after the packing compaction, therefore has not been subjected to the ultraviolet light and the oxygen erosion, therefore completely may satisfy the permanent construction request.

- Q: Can geogrids be used in reinforcement of soil-cement mixtures?

- Yes, geogrids can be used in the reinforcement of soil-cement mixtures. Geogrids are commonly used to improve the strength and stability of soil-cement composites by distributing loads, reducing settlement, and preventing cracking. They enhance the overall performance of soil-cement mixtures and are widely utilized in various civil engineering applications.

- Q: Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are often employed in such situations to stabilize the soil and prevent erosion by providing reinforcement and increasing the overall strength of the slope.

- Q: Each side of geogrid is not less than 3 meters, what does it mean?

- Design requirements obviously not for this purpose, I consider is not a few geogrid lap width than the roadbed width of three meters, and then backfill roadbed soil after 60 or 80 cm and then the two sides of the geogrid back.

- Q: Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are often used to reinforce soil structures and provide stability, which can be beneficial in supporting the infrastructure and components of geothermal energy systems. They can help prevent soil erosion, provide load-bearing capacity, and enhance the overall performance and longevity of the system.

Send your message to us

Asphalt Reinforcement Geogrids for Roadbed Strengthening

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords