Road Reinforcement Geogrids for Dikes, Dams, and Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

EGA50-50, EGA80-80, EGA100-100

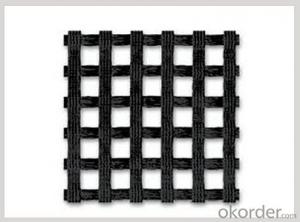

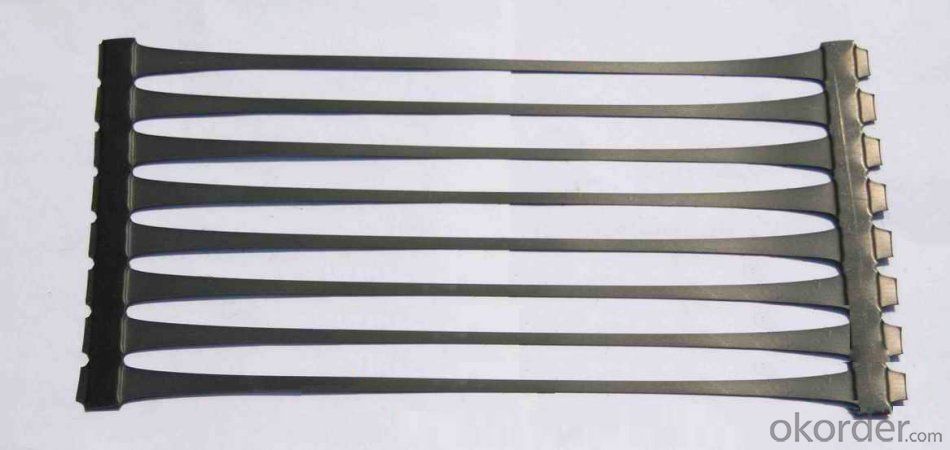

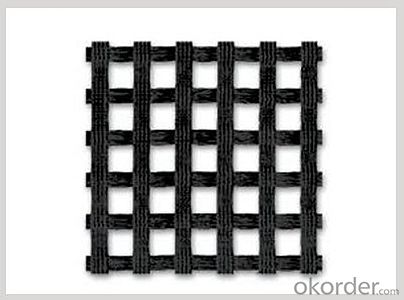

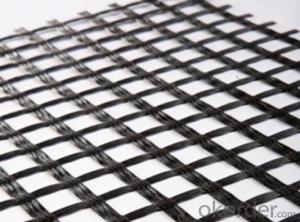

High density Biaxial Geogrids

Biaxial geogrids are designed to have roughly the same tensile strength in both directions and to distribute loads over a wider area, increasing the load capacity of the soil. Base reinforcing geogrids interlock with the aggregate to confine the base and reinforce the subgrade. In paved or unpaved applications, they reduce rutting and help maintain the desired aggregate depth.

CNBM offers BaseGrid biaxial geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate. The two grids are offset before welding or stitching, creating a stable, continuous sheet with random-sized apertures for improved soil interaction.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: PVC HF what is the material PVCHF bidirectional geogrid is like?

- Polyvinylchloride, PVC: polymer with random configuration of repeating units

- Q: How do geogrids enhance the stability of steep slopes?

- Geogrids enhance the stability of steep slopes by providing reinforcement and increasing the tensile strength of the soil. They act as a barrier, distributing the load and preventing soil erosion. This reinforcement helps to prevent slope failure and ensures the long-term stability of the slope.

- Q: Can geogrids be used in reinforcement of underground storage facilities for hazardous materials?

- Yes, geogrids can be used in the reinforcement of underground storage facilities for hazardous materials. Geogrids are commonly used in civil engineering and construction projects to enhance the stability and load-bearing capacity of soil structures. By incorporating geogrids into the design of underground storage facilities, they can provide additional reinforcement and prevent soil movement or collapse. This is particularly important when storing hazardous materials, as it helps maintain the integrity and safety of the storage facility.

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and enhance the stability of the soil, preventing erosion and minimizing settlement. They distribute loads efficiently, increasing the overall strength of the embankment and ensuring long-term stability for pipeline crossings.

- Q: What is the recommended geogrid junction spacing for specific applications?

- The recommended geogrid junction spacing for specific applications varies depending on factors such as the soil type, slope angle, and anticipated loads. It is best to consult the manufacturer's guidelines or work with a geotechnical engineer to determine the appropriate spacing for a particular project.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids are commonly used to provide reinforcement to geosynthetic clay liners in waste containment facilities. They enhance the stability and strength of the liners, preventing them from tearing or shifting under heavy loads, and improving overall containment system performance.

- Q: What are the standards for geogrid testing and certification?

- The standards for geogrid testing and certification typically include various parameters such as tensile strength, junction strength, aperture size, creep behavior, and durability. These tests are conducted according to industry-recognized standards such as ASTM D6637, ISO 10319, and GRI-GG2. The certification process ensures that geogrids meet the required performance criteria and can be used effectively in geotechnical applications.

- Q: How do geogrids improve the performance of reinforced soil retaining walls?

- Geogrids improve the performance of reinforced soil retaining walls by adding tensile strength and enhancing stability. They are typically made from high-strength materials such as polyester or polypropylene, which provide reinforcement to the soil mass. When geogrids are incorporated into the retaining wall design, they effectively distribute the applied loads, reducing the stress on the soil and preventing wall failure. Additionally, geogrids increase the overall stiffness of the reinforced soil, minimizing deformation and settlement. This reinforcement technique enables the construction of taller and more structurally sound retaining walls, ensuring long-term stability and improved performance.

- Q: Are geogrids effective in preventing soil erosion on slopes without vegetation?

- Yes, geogrids are effective in preventing soil erosion on slopes without vegetation. Geogrids are synthetic materials that are designed to reinforce and stabilize soil, providing structural support to prevent erosion. They are commonly used in areas where vegetation is not present or cannot be established, such as construction sites or steep slopes. Geogrids improve soil stability, distribute load forces, and enhance water drainage, effectively reducing soil erosion.

- Q: What is the meaning of 80 in geogrid TGSG80

- Hello, this is a two-way stretch polypropylene geogrid.

Send your message to us

Road Reinforcement Geogrids for Dikes, Dams, and Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords