Geogrid for Plastic for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geogrid for Plastic for Architectural Engineering

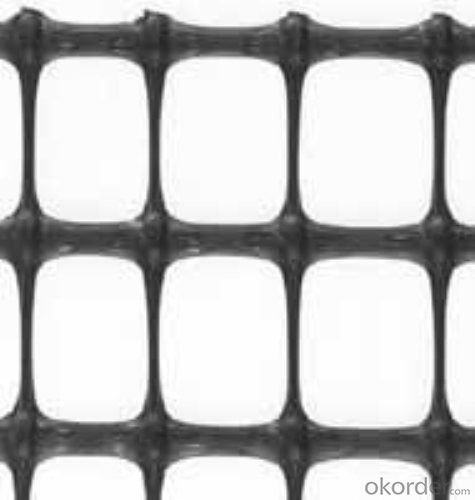

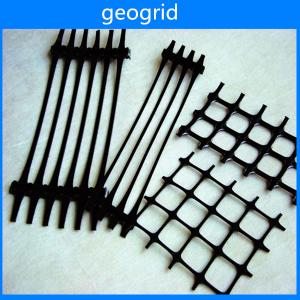

Description Of Geogrid for Plastic for Architectural Engineering

The architectural engineering grid is one of the main materials for the synthesis of the soil. It has a unique performance and effect compared with other synthetic materials.

Geogrid are classified into four categories: Plastic geotechnical grille, steel geotechnical grille, glass fiber geogrid and polyester warp knitting polyester geotechnical grille.

Main Features of Geogrid for Plastic for Architectural Engineering

The polymer in the manufacture of plastic clay grid will be re aligned with the heating process and the orientation of the polymer, strengthening the link between the molecular chain, to achieve the purpose of improving the strength of the polymer. Its elongation is only 12% to 17% of the original plate. If in geogrid adding carbon black anti aging materials, which has good acid resistance, alkali resistance, corrosion resistance and anti-aging etc. durability.

Applications of Geogrid for Plastic for Architectural Engineering

This product is mainly used in coal mine underground mining to help, can be used as a bolt roadway, supporting the roadway, bolt shotcrete roadway and other supporting materials. When used at the top of the double layer, the double layer is used in combination.

IMages of Geogrid for Plastic for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: Can earthwork products be used for constructing horse riding arenas?

- Yes, earthwork products can be used for constructing horse riding arenas. Earthwork products such as gravel, sand, and clay can be used as base materials to create a suitable and stable surface for horse riding arenas. These materials provide the necessary foundation to support the weight and movement of horses, ensuring a safe and functional riding area.

- Q: What are the advantages of using geotextiles in shoreline habitat restoration projects?

- Using geotextiles in shoreline habitat restoration projects offers several advantages. Firstly, geotextiles help stabilize the soil and prevent erosion, providing a stable foundation for shoreline vegetation to grow and flourish. This helps protect the shoreline from further degradation and enhances habitat resilience. Additionally, geotextiles act as a physical barrier, preventing invasive species from infiltrating the restoration site and allowing native plants to establish and thrive. Moreover, these textiles facilitate water filtration and drainage, improving water quality and creating a healthier ecosystem for aquatic species. Overall, geotextiles play a crucial role in enhancing the success and long-term sustainability of shoreline habitat restoration projects.

- Q: Are earthwork products easy to install and maintain?

- Yes, earthwork products are generally easy to install and maintain. These products, such as retaining walls or drainage systems, are designed to be user-friendly and can often be installed with basic tools and equipment. Additionally, they require minimal maintenance once installed, usually only requiring periodic inspections and basic upkeep.

- Q: Why beginners or senior civil engineering and technical personnel are required to continue to learn civil engineering materials

- Urban development is much faster than mass maternity leave

- Q: What are the specific applications of geotextiles in earthwork projects?

- Geotextiles have various applications in earthwork projects, such as soil stabilization, erosion control, filtration, drainage, and separation. They can be used to reinforce soil, prevent erosion by acting as a barrier, filter water, and separate different soil layers. Geotextiles are commonly used in road construction, slope stabilization, landfill engineering, and other civil engineering projects to enhance the performance and longevity of the structures.

- Q: Can earthwork products be used for creating outdoor kitchens?

- Yes, earthwork products can be used for creating outdoor kitchens. Earthwork products such as natural stones, bricks, and concrete can be utilized for building the foundation, countertops, and other structural elements of an outdoor kitchen. These materials offer durability, strength, and a natural aesthetic that complements the outdoor environment. Additionally, earthwork products can be shaped and designed to accommodate various features like grills, sinks, and storage areas, making them suitable for constructing functional and visually appealing outdoor kitchens.

- Q: Can geosynthetics be used for lining wastewater treatment plants?

- Yes, geosynthetics can be used for lining wastewater treatment plants. Geosynthetics, such as geomembranes and geotextiles, provide a cost-effective and efficient solution for containing and controlling wastewater in treatment plants. They offer excellent resistance to chemical and biological degradation, as well as superior durability, flexibility, and impermeability, which are crucial for preventing leakage and protecting the environment. Additionally, geosynthetics help in reducing installation time and maintenance costs, making them a suitable choice for lining wastewater treatment plants.

- Q: How do earthwork products contribute to wetland restoration?

- Earthwork products play a crucial role in wetland restoration by providing the necessary materials for building and shaping wetland features. These products, such as soil, clay, and rock, are used to create berms, levees, and other structures that help retain water and prevent erosion in wetland areas. By using earthwork products, wetland restoration projects can successfully recreate natural hydrological conditions, improve water quality, and enhance overall habitat suitability for wetland species.

- Q: Can earthwork products be used for fish passage construction?

- Yes, earthwork products can be used for fish passage construction.

- Q: What is the purpose of using geotextile tubes in dredging projects?

- The purpose of using geotextile tubes in dredging projects is to provide efficient and effective dewatering and containment solutions. These large, fabric tubes are filled with sediment and water from the dredging process, allowing the water to drain out while retaining the solid material. This helps to separate and consolidate the dredged material, making it easier to dispose of or repurpose. By using geotextile tubes, dredging projects can minimize environmental impact and manage sediment in a controlled manner.

Send your message to us

Geogrid for Plastic for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords