Flexible High Modulus Geogrid for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

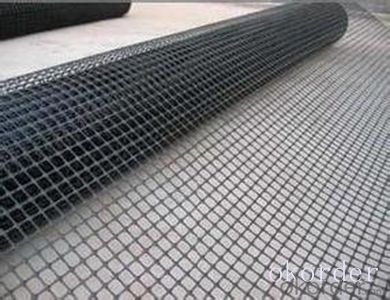

Geogrids are flat structures, where two or more series of strip elements made of polyester coated with polyethylene, are linked at regular intervals by means of bonding.

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

3.It can be applied in rail, road slope's protection;

4.It can be applied to enhance the culvert;

5.It can be applied as a secondary enhancement after the uniaxial Geogrid soil enhancement, further enhance the soil;

6.It can be applied in mining, tunnel reinforcement.

7.Network used for animal and husbandry;

8.Network used for cage fishing.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the price of geogrid? There are geogrid manufacturers that good?

- Including geomembrane, geotextile, geogrid and so on, you can directly geogrid Li Huaiqing, you can also click on my information, I have to rest assured, welcome to inquire! Looking forward to your cooperation!

- Q: Can geogrids be used in erosion control applications?

- Yes, geogrids can be used in erosion control applications. Geogrids are commonly used to reinforce soil and prevent erosion by providing stability to the ground. They help to distribute loads, improve soil retention, and increase the resistance to erosion caused by water or wind.

- Q: What is the typical geogrid roll length for specific applications?

- The typical geogrid roll length for specific applications can vary depending on the specific project requirements and the manufacturer's offerings. However, it is common to find geogrid rolls with lengths ranging from 50 to 500 feet.

- Q: Geogrid what to do

- Test items include: strength, elongation at break, amount of glue, weight, mainly to measure the strength of the grid.

- Q: How much cheaper than steel reinforced plastic geogrid

- Specifications of different prices, the general specification of 4 to 6.5 square.

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- The direction of the pulling force is consistent with the direction of the road extension

- Q: Characteristics of steel plastic geogrid

- 1 high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type.2, steel plastic composite geogrid vertical wire warp rib braided mesh, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low.

- Q: Are geogrids suitable for use in slope stabilization for mining tailings dams?

- Yes, geogrids are suitable for use in slope stabilization for mining tailings dams. Geogrids provide reinforcement and stability to the slopes, preventing erosion and potential failure of the dam. They are designed to withstand high loads and are effective in controlling soil movement, making them an ideal solution for slope stabilization in mining tailings dams.

- Q: How do geogrids help in reducing the risk of slope instability?

- Geogrids help in reducing the risk of slope instability by reinforcing the soil and providing additional strength to the slope. They act as a stabilizing agent by increasing the soil's shear resistance and preventing it from sliding or collapsing. This reinforcement helps in distributing the forces exerted on the slope, reducing the potential for slope failure and improving overall stability.

- Q: What criteria should be used in the construction of Geogrid

- A brief introduction of geogrid:A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and polyester warp knitted polyester geogrid.

Send your message to us

Flexible High Modulus Geogrid for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords