Woven Polyester Geogrid For Soil Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

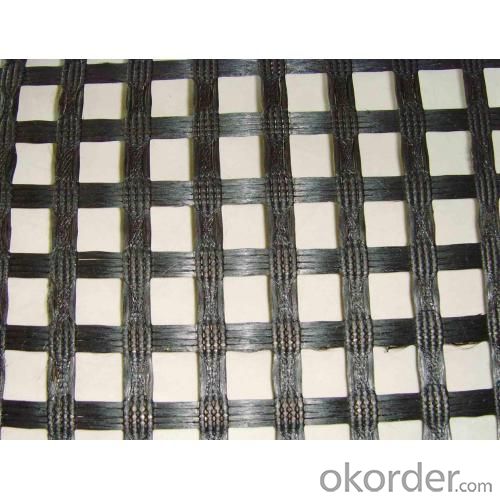

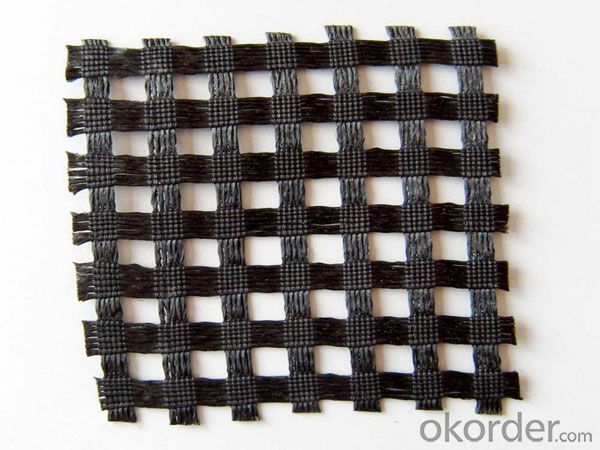

Structure of Woven Polyester Geogrid:

Woven Polyester Geogrid has high intensity, the elongation ratio is low, thermostable, the module is high, toughness is good, anti-corrosive, long life and so on characteristics, so widely applies to the old cementroad surface,runway's

service, the river bank, the side slope protection, project domains and so on road bridge connection

surface enhancement..

Main Features of Woven Polyester Geogrid :

Woven Polyester Geogrid for soil reinforcement

Reinforcement of the surface of road and bridge.

High tensile strength, low elongation

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

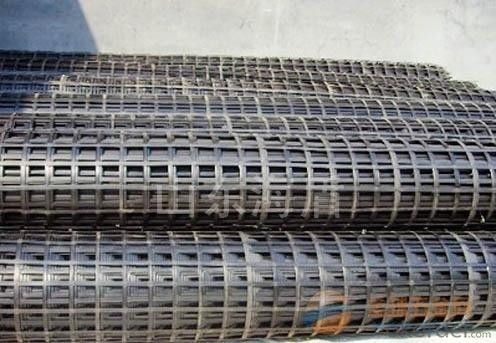

Woven Polyester Geogrid Images

Woven Polyester Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Geogrid manufacturers and the price is how much?

- Geogrid is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Uniaxial Plastic Geogrid

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids provide reinforcement and stability to the soil, preventing erosion and slippage along the riverbank. They are effective in enhancing the strength of the soil while allowing for proper drainage. Geogrids can be installed easily and are a cost-effective solution for protecting riverbanks against erosion and maintaining their stability.

- Q: Are geogrids suitable for reinforcing bridge abutment backfills?

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids provide increased stability and load-bearing capacity to the soil, preventing erosion and settlement. They distribute the load evenly, reducing the risk of structural damage to the bridge abutment. Additionally, geogrids improve the long-term performance and durability of the backfill materials.

- Q: Can geogrids be used for reinforcement in soft soils?

- Yes, geogrids can be used for reinforcement in soft soils. Geogrids are commonly used in geotechnical engineering to improve the stability and strength of soft soils. They provide additional tensile strength and distribute loads more evenly, reducing settlement and improving overall performance in soft soil conditions.

- Q: Anchorage length of Geogrid

- B. on the new cement concrete road surface, glass fiber grid should be placed between semi-rigid base and rigid cement concrete seal.C. on the old asphalt pavement repair, you can use the fuel injection method, anchoring method, self-adhesive method, in the original pavement laying fiberglass grille. Can also be done on the original pavement 20mm-30mm fine asphalt concrete leveling layer, and then laid fiberglass grille, and then paved asphalt concrete surface, the thickness should be 60-100mm.

- Q: Are geogrids cost-effective?

- Yes, geogrids can be considered cost-effective. Geogrids help to improve the stability and performance of soil structures, reducing the need for excessive amounts of expensive construction materials. They also have a longer lifespan compared to traditional methods, resulting in lower maintenance and replacement costs over time. Additionally, geogrids can enhance project efficiency by reducing construction time and labor costs.

- Q: How do geogrids reduce settlement in embankments?

- Geogrids reduce settlement in embankments by increasing the stability and load-bearing capacity of the soil. They distribute the applied load over a larger area, thus reducing the stress on the soil and minimizing settlement. Additionally, geogrids improve soil compaction and prevent lateral movements, thereby enhancing the overall integrity and longevity of the embankment.

- Q: How do geogrids improve the stability of steep slopes?

- Geogrids improve the stability of steep slopes by providing reinforcement and increasing the shear strength of the soil. They are placed within the soil mass to distribute the applied loads more evenly, reducing the potential for slope failure. Additionally, geogrids enhance the interlocking of soil particles, preventing soil movement and erosion, which ultimately contributes to improved slope stability.

- Q: What are the specifications and models of Geotextiles and geogrids on the highway

- Steel plastic composite grille GS30-30 GS60-60 GS80-80 GS150-150 width 4-6m meters GS80-60 GS50-50;Glass fiber grille BJG35-35 BJG60-60 BJG80-80 BJG100-100 width 1-6 meters (BJG50-50);

- Q: What is the lifespan of geogrids?

- The lifespan of geogrids can vary depending on various factors such as the quality of the material, environmental conditions, and usage. However, geogrids are typically designed to have a lifespan of 20 to 50 years.

Send your message to us

Woven Polyester Geogrid For Soil Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords