Heat-resistant Silicone Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Heat-resistant Silicone Rubber Seal Strip:

1. Brief Description of Heat-resistant Silicone Rubber Seal Strip

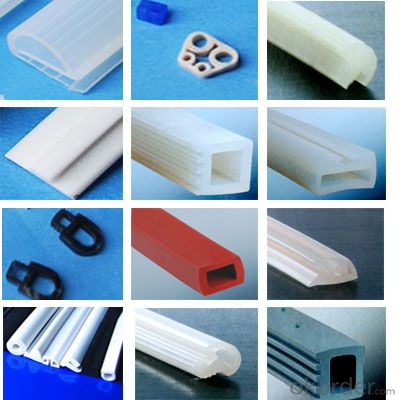

We can customize any kinds of rubber products,such as extruded rubber tube, profiles; molded rubber o ring, gaskets; rubber sheets ,cold shrink cable accessories any other shape of rubber products.

2. Main Features of Heat-resistant Silicone Rubber Seal Strip

1. Ambient temperature from under 50 degree to 300 degree.

2. with backed tape, easy to install

3. High Impact Resistance, good process ability shockproof, soundproof, heatproof, insulation.

4. Different color and shape can be made according to your drawing

5. Transparent, smooth, Soft and flexible. Non-toxic tasteless

6. Function: windows, doors

7. High strength, flame resistant

8. Good elasticity

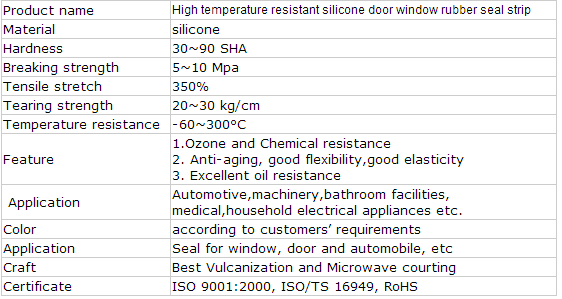

3. Main Specification of Heat-resistant Silicone Rubber Seal Strip

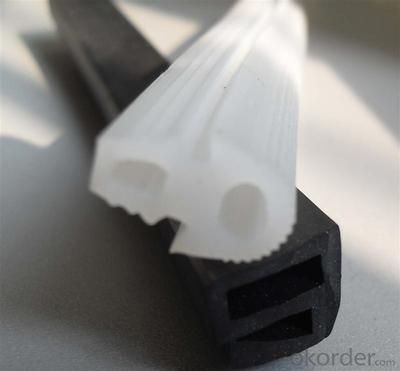

4. Pictures of Heat-resistant Silicone Rubber Seal Strip

5. FAQ

1.Q:Are you a factory or trading company?

A:We are a factory.

2.Q:Can you ensure your quality?

A:Yes,our products have past ISO certificate.We have specialized technical department and

QC team,we will strictly check the material.color,size,performance of the sample step by

step.And every item will be checked before packing.

3.Q:Can you delivery the products on time?

A:Our factory have a production capacity of 400T/month.We will calculate the special delivery

time for you,and ensure the arranged delivery time.

4.Q:Why I choose your products?

A:We can produce the products strictly as your request,and our price is according to the

product material cost,technology cost,labor cost,and other necessary cost.Our price will be

reasonable.

5.Q:Can I get some samples?

A:We offer free sample.

6.Q:Can I visit your factory?

A:Yes, welcome to visit our factory.

- Q: What are the application fields of waste tire rubber powder?

- Waste tire rubber powder modified asphalt for highway, waterproofing materials, modified concrete, modified coating, railway sleepers, rubber brick, machine pad, cushion, cushion and other types of subgrade gasket and fenders, sound-absorbing materials, road sealant, shoes, carpet padding, tire pad, car body, bottom sealing rings miscellaneous pieces of rubber, etc..

- Q: Is silicone good or rubber good?

- Rubber is divided into natural rubber and synthetic rubber, natural rubber structure is isoprene polymer, synthetic rubber such as polybutadiene rubber, chloroprene rubber, styrene butadiene rubber. When rubber is deformed by the external force, the crosslinked rubber has the ability to recover quickly, and has good physical and mechanical properties and chemical stability.Silicone rubber is mainly composed of high molecular weight linear polysiloxane. The Si-O-Si key is the basic bond formed, mainly methyl silicon atoms connected, introduced a very small amount of unsaturated groups in side chain, intermolecular interactions, molecular spiral structure, methyl arrangement and can freely rotate outward, thus vulcanized silicone rubber has excellent resistance to high and low temperature (-100~315 DEG C). Weather, water repellent, electrical insulation, physiological inertia and other characteristics, are widely used in military, medical, industrial and agricultural production and people's daily life. Most importantly, there is no toxicity, as usual in pacifiers and breast implants.

- Q: Excuse me, what is in the rubber rubber, glue them, what is the difference?

- No rubber vulcanization glue all over vulcanization.

- Q: How to distinguish between rubber and polyvinyl chloride?

- The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- The relationship between the hardness and tensile strength of rubber pad: the higher the hardness, the greater the tensile strength.

- Q: What kind of product is suitable for rubber trimmer? Where's the rubber trimmer?

- Rubber products, silica gel products, special rubber products only need to have the rubber parts of the dismantling groove, and the diameter of the rubber inside the 100MM can be used as trimming machine.

- Q: Can the rubber surface be painted with paint?

- Rubber surface of the original jet printing pattern, etc., how to remove clean, and does not affect the appearance and rubber layer: the way is solvent oil!

- Q: How do you remove the black dirt on the rubber?

- Apply toothpaste to the stain and brush it again and again as clean as newWith Senna water and kerosene on rubber and iron grinding interpolation results are goodThe black dirt on the rubber can also be removed by diluting it with alcohol

- Q: Is carbon black and conductive carbon black used in rubber?

- Carbon black is divided into two major categories according to its use and usage:1. Rubber carbon black2, non rubber carbon black (or special carbon black, dedicated carbon black), including pigment carbon black, conductive carbon black, carbon black used for plastics, and a variety of special carbon black and so onMay refer to: Li Bingyan edited the "carbon black production and Application Manual."

- Q: How to distinguish between plastic products and rubber products, toys?

- There are several ways to distinguish between plastic and rubber products:1, color: plastic products, relatively transparent color, relatively strong, and rubber products are relatively poor transparency;2, thickness: plastic product thickness than rubber products thin;3 hardness: general plastic products than rubber products slightly hard;4: texture: plastic products are more smooth or microstrip lines, and rubber products on the surface of some of the same as human skin, texture deeper or more rough;5, taste: plastic taste, the taste of micro strip plastic, and rubber products are micro rubber rubber flavor;6, weight: general plastic products will be slightly lighter than rubber products.

Send your message to us

Heat-resistant Silicone Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords