Rubber Door Seal with High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Door Seal with High Quality and Low Price:

1. Brief Description of Rubber Door Seal with High Quality and Low Price:

Our products mainly include rubber part,rubber seal,silicone rubber, rubber extrusion,rubber mat, rubber sheet etc. Now our products have been exported to the USA, Argentina, Chile, England, Germany,Sweden, Italy, Poland, Israel, Singapore, Korea and South Africa, totally over 30 countries.

2. Main Features of Rubber Door Seal with High Quality and Low Price:

1) We can customize your brands, and provide high quality products with competitive price.

2). We provide thoughtful, prompt and safe services to every customer.

3). Offer Samples in FREE!

4). More order, More discount!

5). Provide Cheap & Safe Shipping or Express!

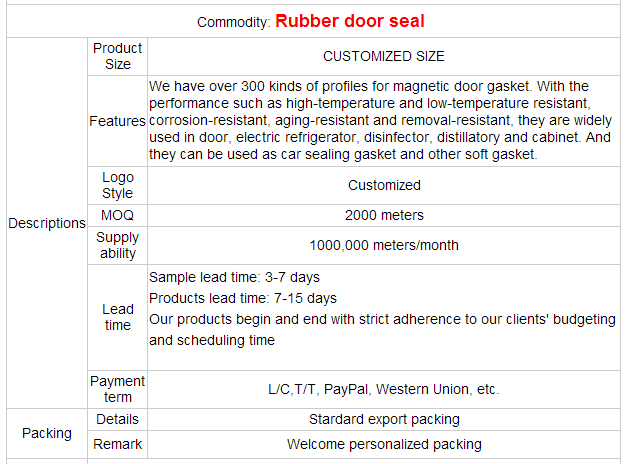

3. Main Specification of Rubber Door Seal with High Quality and Low Price:

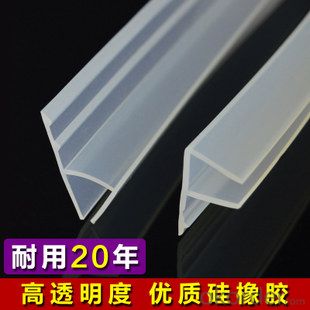

4. Pictures of Rubber Door Seal with High Quality and Low Price:

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: What problems need to pay attention to when inflating the pipe?

- Rubber pipeline plugging bag should keep the inner pressure of the gasbag is uniform when inflated, inflated slowly rising inflation, observe the pressure gauge without change, such as pressure gauge shows rapid rise in inflation is too fast, the inflation rate should slow down, stop valve will tighten slightly, reduce the inlet velocity, or the speed is too fast, faster than pressure is likely to break into the rubber balloon. - Zhang

- Q: Classification of other rubber sheets of wear-resistant rubber plates

- RIT flat wear-resistant plywoodNon slip and relatively ordinary wear, usually used in less tension fabric, nylon belt, roller wrap, or ordinary environment of the drum wrapped plastic processing.RIT type wear resistant rubber plateThe surface of the rubber plate is of a rhombus shape, which has a strong anti slip and abrasion resistance. It is usually used in the fabric belt and middle and high strength steel belt and roller package processing. It is the most frequently used roller wrapped rubber sheet at present. Especially 10mm and 12mm thick rhombus rubber sheet.

- Q: Process for producing rubber products

- In order to adapt to the different conditions of use, to achieve a variety of performance, also in order to improve the performance of rubber products and reduce the cost must be added with different chemicals in raw. Mixing is the mixing of raw rubber and compound mixing, placed in the mixing machine by mechanical mixing with the role of agent, uniformly dispersed in rubber in a process. Mixing is an important process in the production of rubber products. If the mixture is uneven, it can not give full play to the role of rubber and mixture, and affect the performance of products. People get glue mixing after the production of various rubber products for mixing it is semi-finished materials, rubber products, commonly known as the glue are usually sold as a commodity buyers can directly process material, need to use the rubber vulcanization. According to the formula, a series of different grades and varieties with different performances are selected.

- Q: How can rubber products prevent fading?

- For example, footwear product quality inspection process found in the yellowing resistance of some poor performance materials, shallow white soles during the experiment; and meet many enterprises in the production of light, white shoe sole in the process of use and storage in color yellowing phenomenon; even found some enterprises in the production of light, white sole test HG/T3689-2001 "footwear yellowing resistance test method" to determine the material in the approximation of the sun light, ultraviolet radiation resistance to yellowing ability, the observed color change of sample surface degree of occurrence is not large, but the sole is made into shoes in the process of use and storage is prone to yellow phenomenon.

- Q: What are the causes of chapped rubber products?

- This is the aging phenomenon of rubberAging refers to the polymer materials (including rubber, plastics, fiber and so on) in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors, its performance gradually deteriorated, resulting in the final loss of use value

- Q: What are the causes of the rubber products breach?

- It's aging of rubberAging refers to the polymer materials (including rubber, plastics, fiber and so on) in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors, its performance gradually deteriorated, resulting in the final loss of use value.

- Q: What is the temperature of ordinary silicone rubber resistant to low temperature?

- Heat resistance of silicone rubber in the air is much better than that of organic rubber, at 150 DEG C, the physical and mechanical properties basically unchanged, semi permanent use, under the temperature of 200 DEG C can be used continuously for more than 10000h; 380 DEG C can be used for some time. Silicone rubber is therefore widely used as rubber parts in high temperature applications.

- Q: Does the fuel pipe for automobiles belong to rubber products?

- If it is a diesel car, then the high pressure part of the metal pipe only, in the low pressure part of the rubber tube.

- Q: Which kind of rubber has the best wear resistance?

- Ding Qing rubber (nitrile, butadiene, rubber)It's also called NBR.Butadiene and acrylonitrile are obtained by emulsion polymerization. NBR is mainly produced by low temperature emulsion polymerization. It has excellent oil resistance, high wear resistance, good heat resistance and strong adhesive force. Its disadvantages are poor resistance to low temperature, poor ozone resistance, poor electrical properties, and slightly lower elasticity.

- Q: How can rubber be preserved without decay?

- To preserve the rubber, do the following.1, to avoid long-term direct sunlight, the sun is too strong on the aging of rubber is killed, rubber is usually black, absorbing ability, so will cause the temperature rise, and then the physical properties change, the direct result is soft.2, avoid high temperature environment, said in front of direct sunlight will cause high temperature deformation. Another disadvantage of high temperatures is that it can cause rubber to melt.

Send your message to us

Rubber Door Seal with High Quality and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords