Waterproof Rubber Seal Strip with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Rubber Seal Strip with High Quality:

1. Brief Description of Waterproof Rubber Seal Strip with High Quality

We produce rubber seal strip according to customer's requirements, samples, or 2D,3D drawing, any format. If you are interested in our factory please do not hesitate to ask for a similar one or OEM&ODM made.

2. Main Features of Waterproof Rubber Seal Strip with High Quality

1).Environmental safety, good insulation, high temperature, low compression set, strong resilience;

2).smooth surface, uniform density foam;

3).acid, anti-aging, non-toxic;

4).good non-stick surface, good air permeability;

5).using 100 percent high-quality rubber raw materials, and rigorous testing

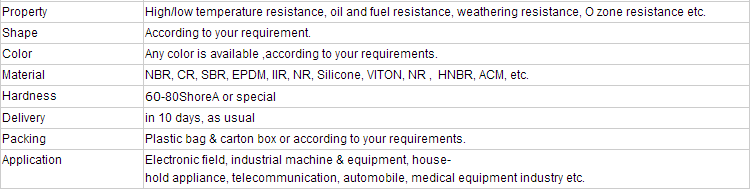

3. Main Specification of Waterproof Rubber Seal Strip with High Quality

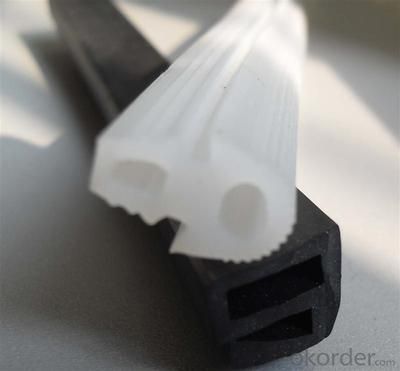

4. Pictures of Waterproof Rubber Seal Strip with High Quality

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: What is the pressure on rubber products during vulcanization?

- Usually, the selection of curing pressure need to consider several factors, namely rubber formulation, rubber plastic size, forming die structure (filling pressure, injection pressure, injection type), type of curing equipment (flat vulcanizing machine, vulcanizing machine, injection machine, injection of sulfur with sulfide vacuum machine etc.) and product structure features.

- Q: How to distinguish between rubber and polyvinyl chloride?

- Adhesive (Rubber): highly elastic polymeric material with reversible deformation.At room temperature, elastic, in a small rubber under the action of external force can produce greater deformation, remove the external force can restore the original state. Rubber is a completely amorphous polymer, its glass transition temperature is low, the molecular weight is often very large, more than hundreds of thousands.

- Q: How does the rubber part of the watch become yellow?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: What are the forming methods of rubber products?

- Calendering is the process in which material is subjected to elongation. The main equipment for rolling forming is three roller or four roller calender. The three roller calender is achieved by rotating the pressure of the two roller. When the rubber material passes through the roller gap, the rubber strip is expanded into a certain sectional shape under the action of pressure, or the process of gluing is realized on the fabric. It is used for sizing, pressing, spinning, gluing and gluing of textile and steel cord, as well as the laminating of film and film, film and adhesive fabric.The basic procedure of calendering process includes: mixing and preheating glue; fabric guiding and drying (and sometimes dipping); rubber sheeting in four roll and three roll calender on or in textile and rubberized calendering semi-finished products cooling, crimping, cutting and placing etc..In rolling before the need to preprocess the rubber and textile, rubber calender before entering, to turn it in the hot refining mill, this process is called thermal refining or preheating, the purpose is to improve the mixing uniformity of refined rubber material, further increase the plasticity, increasing the temperature increase high plasticity. In order to improve the bonding performance of rubber and textile, ensure the rolling quality, need drying of the textile fabric, moisture content control in 1% ~ 2%, the moisture content is too low, the textile hardens, easily damaged during the calendering, high water content, poor adhesion.

- Q: How can there be a crack in the rubber ring?

- Suggest:1, processing aids (stearic acid, paraffin wax or high molecular wax) increased appropriately!2, operating oil appropriate two plus -5 copies!3. Proper curing temperature. Select according to rheometer!4. Re adjust the parameters of the processed species (such as temperature, exhaust, material thickness, etc.)

- Q: Is rubber flame retardant?

- Mainly to see the use of related products, for example, the glass door rubber strip is flame retardant, and the vehicle's internal and external tires are not flame retardant.

- Q: What are the causes of the rubber products breach?

- First: the use of rubber joints in the process of linking the length is not enough to force beyond the length of the link, the expansion of the scope of contraction may also splitSecond: rubber joints, the strength of the link is relatively low, then if the adhesive method is not accurate, the strength of the joint will be lower, there may be crackingThird: rubber joints after installation, in other places free here beyond the extension range of pipe strap, there may be cracking.Fourth: rubber joints in the outdoor adverse weather, explosion, sun, etc., lower than the use of temperature may also crack.Fifth: in the process of production of vulcanized rubber joint used in rubber function is not good or has been since sulfur failure, excessive grinding, wire rope and other parts of the rust, the joint strength will be greatly reduced, when in use, will likely easily disconnect joint phenomenon

- Q: EPDM rubber foam?

- Three yuan ethylene propylene diene rubber (EPDM) is used as matrix, and azo two, AC and HOBSH are used as foaming agents, in order to systematically and quantitatively study the preparation process of EPDM foam material and the relationship between structure and properties of foamed material. At present, most of EPDM rubber foam material with low reinforcing carbon black filler, fine particles of carbon black can avoid the difficult problem of dispersion and high viscosity, but now the industry of light colored rubber products demand more and more, so this paper using silica as reinforcing filler rubber, studied the preparation process of EPDM foam rubber and the effects of molding conditions on the foaming process. Subsequently, the change of accelerator, filler, foaming agent and the amount of paraffin oil was analyzed. The curing properties, mechanical properties and SEM analysis were carried out, and the influence of various factors on the structure and properties of foamed material was discussed. The influence law of each formula factor on foaming is summarized, and the optimum formula dosage is expected to be found. Finally, we also through the compression behavior of stress-strain curves of EPDM rubber foam materials with different density, the energy absorption efficiency of E and I analysis of the ideal parameters of EPDM foam energy absorption characteristic of absorbing ability of W and.

- Q: What adhesive does rubber and wood have better glue?

- Rubber and wood bonded with ergo5500 rubber glue better.

- Q: How can rubber products be softened?

- Rubber softener for fluid or semi fluid, dangerous goods, should be stored in the rain (the most important) ventilation dry place shading.A package (drums, plastic barrels, plastic bags), according to the needs of the customer.

Send your message to us

Waterproof Rubber Seal Strip with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords