Stable Quality Anti-noise Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stable Quality Anti-noise Rubber Seal Strip:

1. Brief Description of Stable Quality Anti-noise Rubber Seal Strip

Rubber seal could stop air, water and dust enter the machine system, which could protect the machine boat or automotive parts to be healthy and working well.

2. Main Features of Stable Quality Anti-noise Rubber Seal Strip

1.good anti-friction,anti-aging, anti-corrosion effect

2. Weather proof, vandal proof, and can be shaped, molded, painted and screen printed.

3. Non-corrosive, non-toxic and chemical resistant .

4. Soft with high impact strength .

5. Non-warping and stain proof.

6. Easy to clean and maintain .

7. Easy to operate, including glue, nail, cut or shape.

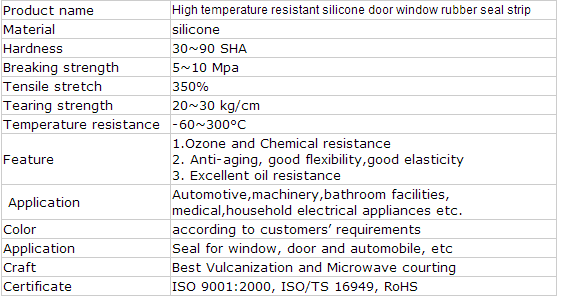

3. Main Specification of Stable Quality Anti-noise Rubber Seal Strip

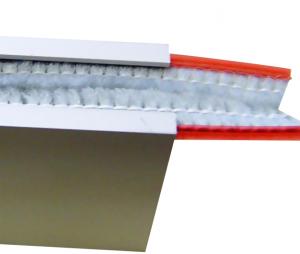

4. Pictures of Stable Quality Anti-noise Rubber Seal Strip

5. FAQ

(1)Q: Are you a factory or trading company

A: We are tading company with import and export lisense and have our own factory.

(2)Q: Do you offer samples of anti-noise rubber seal strip ?

A: We are glad to offer you free samples. New clients are expected to pay for the delivery cost,this charge will be deducted from the payment for formal order.

(3)Q: How about the lead time?

A: Within10-20 days after getting the prepayment.

(4)Q: How can we pay?

A: For small sample shipping cost, you can pay either by paypal or by T/T. And by T/T at sight for large amount of the order.

(5)Q: Can you do CO, Form E, Form F, Form A etc?

A: Yes, we can do them for you.

- Q: What solvent is used to clear the melted rubber layer?

- Dry glue in water does not exceed 1%, in the process can be volatile, but the moisture content is too long, will not only make the rubber easy to mildew during storage, but also the impact of rubber processing, such as mixing with the agent is easy to agglomerate; easy to blister calendering and extrusion process, the bubble or a sponge the curing process etc..

- Q: Is work in rubber products harmful to health?

- The raw material of rubber products is rubber compound, and the rubber compound has five components:Main rubber. Rubber main glue is not toxic.Reinforcing agent. Most of the reinforcing agents are not toxic.Softener. Is the most emollient mineral oils, high temperature volatile hazardous substances.Antioxidant. Some poisonous.Vulcanizing agent. The vulcanizing agent is generally sulfur, sulfur will release a high temperature sulfur dioxide, sulfur dioxide, sulfur dioxide, hydrogen sulfide gas three.

- Q: What does the rubber tire do to people?

- There is damage, rubber tires, generally speaking, emit a smell of polycyclic aromatic hydrocarbons, harmful to health.When the car brakes, tires and ground wear, some suspended particles will also cause some harmful gases.The mist and smoke escaping from the gum at high temperatures often make it difficult for the worker to breathe and absorb a lot of harmful substances.

- Q: What's the difference between silicone products and rubber products?

- Physical properties are different: nitrile rubber products waterproof, weak acid, weak base, anti oil, etc., silicone rubber waterproof, environmentally friendly, non-toxic, good elasticity, appearance, color and appearance.

- Q: Classification of other rubber sheets of wear-resistant rubber plates

- RIT ceramic abrasion resistant rubber sheetRubber surface with uniform ceramic block, can drive the roller and the conveyor belt between the grip of excellence, usually used in all kinds of extreme working conditions, such as muddy, wet, and high wear roller under the environment of rubber processing.

- Q: How to test the abrasion resistance of rubber?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- The most essential difference between plastics and rubber is plastic deformation when plastic deformation occurs, while rubber is an elastic deformation. In other words, it's not easy to restore the original state after plastic deformation, and rubber is relatively easy. Plastic elasticity is very small, usually less than 100, while rubber can reach 1000 or more. Most of the molding process of plastics is finished

- Q: How to clean rubber products?

- Rubber is elastic hot melt thermosetting body, plastic is hot cold setting. Rubber due to different types of sulfide species, its molding and curing temperature range is also a considerable gap, and even can be affected by climate change, indoor temperature and humidity affected. Therefore, the production conditions of rubber products need to be adjusted at any time. If not, the quality of the products may be different.

- Q: Why do rubber products become so long that they seem to melt and become sticky on the surface?

- The main reason for the melting of rubber products is the long usage time or the long time of placing rubber;"Sticky" is because the rubber in the presence of oxygen oxidation reaction, the result is hydroxyl, carboxyl and other polar groups increased. These polar groups are the cause of the sticking of things. In layman's terms, it's equivalent to becoming a self-adhesive.

- Q: What are the causes of the rubber products breach?

- First: the use of rubber joints in the process of linking the length is not enough to force beyond the length of the link, the expansion of the scope of contraction may also splitSecond: rubber joints, the strength of the link is relatively low, then if the adhesive method is not accurate, the strength of the joint will be lower, there may be crackingThird: rubber joints after installation, in other places free here beyond the extension range of pipe strap, there may be cracking.Fourth: rubber joints in the outdoor adverse weather, explosion, sun, etc., lower than the use of temperature may also crack.Fifth: in the process of production of vulcanized rubber joint used in rubber function is not good or has been since sulfur failure, excessive grinding, wire rope and other parts of the rust, the joint strength will be greatly reduced, when in use, will likely easily disconnect joint phenomenon

Send your message to us

Stable Quality Anti-noise Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords