Vacuum Bagging Film-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

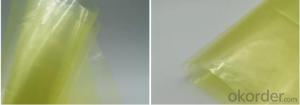

Vacuum Bagging Film

Product Description

Vacuum bagging film is widely used in the composites industry, in vacuum infusion process, vacuum bagging pressure process and autoclave process. It is a technique in which you create uniform pressure to the surfaces of the obiect inside of a bag, holding parts together while the adhesive cures. Pressurizing a composite lamination serves several functions. It removes any trapped air between layers and provides pressure that prevents shifting of fiber orientation during cure. It also reduces humidity and improves the fiber-to-resin ratio in the composite part.

Technique Data

Temperature:150℃

Thickness:65μm,50μm,75μm

Width:≤14m

Length:Tailored

Density:1

Colour:yellow

Longitudinal Tensile Strength:>35MPA

Tensile Strength crosswise:>40MPA

Longitudinal elongation:>300%

Elongation crosswise:>350%

- Q: How can the aluminum alloy window be fixed with the corner and the whole frame?

- Foshan windows and doors mature products manufacturers have matching doors and windows products dedicated corner, because the corner and the doors and windows connected to the width of the frame to coordinate. Generally used corner has 90 degrees, 135 degrees, and universal corner. Albert doors and windows have a complete solution.

- Q: What is the masonry and inclined straight cha cha

- Straight Cha, is unable to stay in the construction of oblique Cha, in addition to the corner and non seismic building, can be set straight cha.

- Q: What is the position of the steering wheel sensor and what is its function?

- Steering wheel angle sensor, a part of the vehicle stability control system, which is installed in the steering column below the steering wheel. It is generally connected to the PCM via the CAN bus. Generally can be divided into analog steering wheel angle sensor and digital steering wheel angle sensor.

- Q: How to solve the corner problem in the kitchen basket?

- How can a reasonable solution to the kitchen corner? Guangdong kitchen basket basket factory iron man to help you solve, corner position is the cabinet where a hidden storage space, how to reasonably use the effective, iron man's products, full pull damping mobs born.

- Q: Does it need extra money to decorate the corner of the plaster line?

- You should say it's the corner where the plaster line is good and the connection is nice

- Q: Large angle hinge is used at the corner of the cabinet

- They are high-end products, the general accessories are pure imports, new technologies and technologies are also used more. So I should know, I hope I can help you!

- Q: Indoor beauty glue, how can you hit the corner, playing perfect?

- General use of aloe vera gel, as long as regular manufacturers are available. Including perfect products.

- Q: What are the applicable industries of corner labeling machines?

- Applicable products: all kinds of cartons, such as poker boxes, mobile phone packaging boxes, etc.. And widely used in printing, food, daily chemicals, electronics, medicine and other industries.

- Q: What's the corner line?

- The composition and content of the corner line body are as follows: (weight percentage): unsaturated polyester resin 22 to 70%; filler 28 to 74%; curing agent 0.1.5%; promoter 0.1.5%; pigment 0.2%.

- Q: What is called "Liu Cha"? Waterproofing materials to leave masonry angle will have Cha, cha.

- Stubble is need to do to prepare for the subsequent construction, waterproofing paving is reserved for the subsequent construction of the lap surface, and masonry can not stay straight cha.

Send your message to us

Vacuum Bagging Film-vacuum infusion process

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches