High Quality EPDM rubber sealing Strip For Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality EPDM rubber sealing Strip For Sale:

1. Brief Description of High Quality EPDM rubber sealing Strip For Sale

EPDM is kind of half a general rubber. It is on the basement of EPM ,It also provided with the advantages of EPM and superior to the workability of the EPM,It is the most stable material for all the rubber products.

2. Main Features of High Quality EPDM rubber sealing Strip For Sale

>Good aging resistance: The aging resistance of EPDM is as well as the Silicone rubber.

>Good comprehensive physical mechanical resistance: It shows excellent performance especially the Static Sealing and Dynamic Sealing.

>Good corrosion resistance.

>Good flexibility : Meet the GB12002-89 standard perfectly.

>Good elasticity.

>Convenient installation

>Competitive price and prompt delivery.

>According to customers’ design.

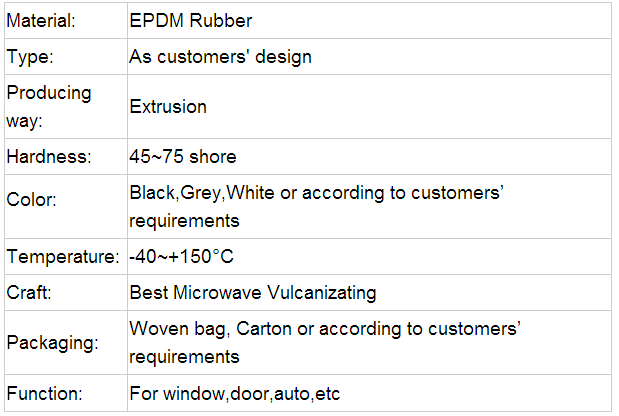

3. Main Specification of High Quality EPDM rubber sealing Strip For Sale

4. Pictures of High Quality EPDM rubber sealing Strip For Sale

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: Rubber and metal have to be sealed before they are too strong

- Different materials and O-ring O-ring compression the change of general material such as NBR, NR, nitrile rubber, natural rubber, chloroprene rubber CR, EPDM three EPDM, HNBR hydrogenated nitrile rubber, silica gel SILICOME SBR Buna, styrene butadiene rubber, SBR, acrylate rubber ACM, compression O-ring or the 20% to calculate. If it is a special material FKM, VITON, PU, FLS silicon fluorine rubber, fluorine rubber, polyurethane, compression of these materials is calculated by 15% o ring.

- Q: Will the rubber ring of the thermos bottle be harmful to the human body?

- For the requirements of thermos bottle rubber gasket Technology: 1, the appearance of white translucent, the use of non yellowing; 2, non-toxic, tasteless, no odor produced by boiling water after 30MIN; 3, the product is soft, the hand 1 times of fracture elongation, small deformation.

- Q: Process for producing rubber products

- In order to adapt to the different conditions of use, to achieve a variety of performance, also in order to improve the performance of rubber products and reduce the cost must be added with different chemicals in raw. Mixing is the mixing of raw rubber and compound mixing, placed in the mixing machine by mechanical mixing with the role of agent, uniformly dispersed in rubber in a process. Mixing is an important process in the production of rubber products. If the mixture is uneven, it can not give full play to the role of rubber and mixture, and affect the performance of products. People get glue mixing after the production of various rubber products for mixing it is semi-finished materials, rubber products, commonly known as the glue are usually sold as a commodity buyers can directly process material, need to use the rubber vulcanization. According to the formula, a series of different grades and varieties with different performances are selected.

- Q: Silicone is silicone rubber? Extracted from there?

- Generally speaking, silica gel can be divided into two categories: organic silica gel and inorganic silica gel according to their properties and components. According to its composition, it is divided into extruded silica gel and molded silica gel.

- Q: How to maintain and store the rubber material?

- Rubber itself is a shelf-life, you can ask the supplier to warranty, above all, as fillers, such as calcium carbonate, carbon black, long time no problem, also have a shelf life of antioxidant promoter, especially individual species. When storing, pay attention to fire prevention, moisture-proof, away from the high temperature, avoid direct sunlight, of course, the general "first in first out" is a must follow the truth.

- Q: How does the rubber part of the watch become yellow?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- The product has good elasticity and anti compression deformation, and has excellent aging resistance. It adopts the microwave vulcanization process to form at one time. The surface is smooth and beautiful, without any trace.

- Q: The action of various ingredients in rubber formula

- Curing system: vulcanizing agent, accelerator, active agent, anti coke agent,

- Q: PVC conveyor belts and rubber belts differ from each other in their respective advantages

- VC conveyor belt, good elasticity, not easy to deformation. Use high strength, high-quality cotton, nylon, polyester canvas as the core, with pure natural rubber pollution-free mixture, made white or light colored, pollution-free, does not affect the food hygiene, odor overlay. PVC belt product formula design is reasonable, accord with the hygiene index, the color is moderate, light and durable. PVC conveyor belt for the food industry or transport of bulk food department, canned and packaged food or food to large size 400, transport capacity from 1 cubic meters / hour to 6000 cubic meters / hour to.

- Q: What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber is a kind of polymer material made of petroleum and natural gas as raw material and polymerized with diene and olefin as monomers.The main purpose of the industrial synthesis of rubber material is cost saving, improving the properties of rubber products, because the natural rubber products price is more expensive, in order to reduce the cost of enterprises have invested a lot of synthetic rubber materials with low cost.

Send your message to us

High Quality EPDM rubber sealing Strip For Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords