Alliance Geogrid

Alliance Geogrid Related Searches

Geogrid Australia Geogrid Machine Universal Geogrid Ace Geogrid Asphalt Geogrid Geogrid Com Allan Block Geogrid Geogrid Layer Grass Geogrid Geogrid Energy Paralink Geogrid Geogrid Grass Geogrid Tbl Terragrid Geogrid Geostar Geogrid Geogrid Alternative Geogrid Anchors Ads Geogrid Miragrid Geogrid Bonded Geogrid Tenax Geogrid Terrafix Geogrid Uniaxial Geogrid Composite Geogrid Interax Geogrid Geogrid Philippines Multiaxial Geogrid Geogrid Blocks Geogrid Walls Dupont GeogridAlliance Geogrid Supplier & Manufacturer from China

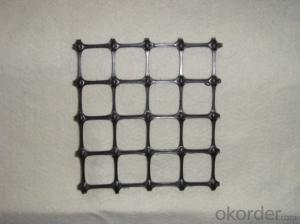

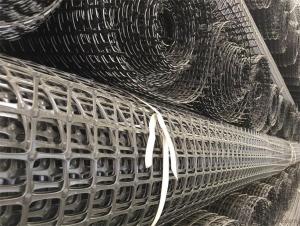

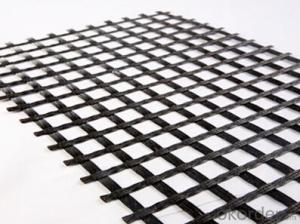

Alliance Geogrid is a range of high-quality geosynthetic products designed to enhance the performance of civil engineering projects. These products are engineered to provide stability and reinforcement to various soil structures, making them an essential component in the construction industry. The geogrids are used in a variety of applications, including road construction, slope protection, and soil reinforcement, offering a reliable solution to improve the overall strength and durability of these projects.Alliance Geogrid products are utilized in numerous scenarios where soil stabilization and reinforcement are required. They are particularly effective in situations where the soil's natural strength is insufficient to support the weight of structures or traffic, such as in the construction of roads, bridges, and retaining walls. By incorporating these geogrids into the soil, engineers can significantly improve load distribution and reduce the risk of soil failure, leading to more stable and long-lasting infrastructure.

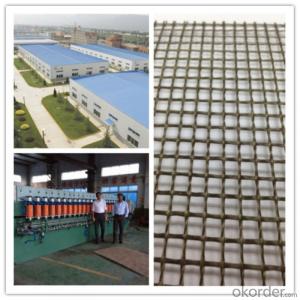

Okorder.com is a leading wholesale supplier of Alliance Geogrid products, boasting a large inventory that caters to the diverse needs of the construction industry. As a reputable supplier, Okorder.com ensures that customers have access to a wide range of geogrid options, enabling them to select the most suitable product for their specific project requirements. With Alliance Geogrid products available in various configurations and strengths, Okorder.com is committed to providing customers with the highest quality materials to achieve optimal results in their civil engineering endeavors.

Hot Products