Fibreglass Geogrids for Asphalt Pavement Reinforcement

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

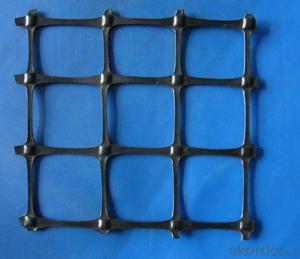

Double-direction geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

2. Product Characteristic:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

3. Decrease underlayer thickness and save manufacturing cost.

3.Specification :

Type: Geogrids

Material: Plastic-Steel,HDPE/PPModel Number: TGDG

Color: black etc.

Length: 50-100m (or at request)

Sample: available

Typical Dimensions mm | Typical Dimensions mm | Typical Dimensions mm | Typical Dimensions mm | Typical Dimensions mm | Typical Dimensions mm |

Pmd | Pmd | Pmd | Pmd | Pmd | Pmd |

Pld | Pld | ||||

Wmd | Wmd | ||||

Wld | Wld | Wld | Wld | Wld | Wld |

Tj | Tj | Tj | Tj | Tj | Tj |

Tmd | Tmd | Tmd | Tmd | Tmd | Tmd |

Tld | Tld | Tld | Tld | Tld | Tld |

Typical Dimensions mm | Typical Dimensions mm | Typical Dimensions mm | |||

4. Reference Picture:

- Q: How do geogrids enhance the stability of steep highway embankments?

- Geogrids enhance the stability of steep highway embankments by providing additional reinforcement and load-bearing capacity to the soil. They act as a strengthening layer, preventing soil erosion and reducing the risk of slope failure. Geogrids distribute the applied loads more evenly, improving the overall stability and preventing soil movement.

- Q: What are the potential drawbacks of using geogrids?

- One potential drawback of using geogrids is the high cost associated with their installation and maintenance. Geogrids are typically made from synthetic materials, which can be expensive to produce and purchase. Additionally, the installation process often requires specialized equipment and skilled labor, further increasing the overall cost. Another drawback is the limited effectiveness of geogrids in certain soil conditions. Geogrids are typically designed to enhance soil stability and reinforce weak or unstable soils. However, in cohesive soils or highly organic soils, geogrids may not provide the desired level of reinforcement. In such cases, alternative solutions or additional measures might be necessary. Moreover, geogrids require proper design and careful installation to ensure their effectiveness. If not installed correctly, geogrids may not perform as intended and could potentially fail. This could result in the need for costly repairs or replacements. Lastly, geogrids may have environmental concerns associated with their production and disposal. Synthetic materials used in geogrids are not biodegradable and may contribute to pollution if not properly managed. Additionally, the manufacturing process of these materials often involves the use of fossil fuels and can generate greenhouse gas emissions. Overall, while geogrids offer numerous benefits in terms of soil reinforcement and stabilization, it is important to consider their drawbacks, including high cost, limited effectiveness in certain soil conditions, installation requirements, and potential environmental impacts.

- Q: What is the recommended geogrid roll width for specific applications?

- The recommended geogrid roll width for specific applications can vary depending on factors such as soil conditions, load requirements, and project specifications. It is best to consult with a geotechnical engineer or geosynthetics expert to determine the appropriate geogrid roll width for your specific application.

- Q: Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q: Unidirectional tensile plastic geogrid manufacturers which good

- The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition

- Q: What are the types of geogrid, respectively, what role?

- Glass fiber grille is made of high quality enhanced E-glass fiber yarn, woven into the substrate with the foreign advanced warp knitting, warp knitting with directional structure, make full use of the fabric yarn strength, improve its mechanical properties, so it has good tensile strength, tensile strength and creep resistance, planar network shaped material and high quality modified asphalt a coating treatment. The following similar compatibility principle, highlighted with the composite performance of asphalt mixture, and fully protect the glass substrate, which greatly improves the wear resistance and anti shearing ability of the substrate, which can be used to enhance the resistance, cracks, rutting of highway asphalt pavement, the end of the problem is difficult to increase the.

- Q: What is the typical width of a geogrid roll?

- The typical width of a geogrid roll is usually between 4 to 16 feet.

- Q: How do geogrids improve the stability of landfills?

- Geogrids improve the stability of landfills by providing reinforcement and preventing soil movement. They distribute loads more evenly, reduce the potential for slope failure, and increase the overall strength of the landfill structure.

- Q: Are geogrids suitable for stabilizing soft soils?

- Yes, geogrids are suitable for stabilizing soft soils. Geogrids are commonly used in civil engineering projects to reinforce and stabilize soft soils by distributing the load more evenly and increasing their bearing capacity. They provide tensile strength to the soil, preventing excessive deformation and potential failure. Additionally, geogrids can improve the overall stability of the soil, reducing the risk of settlement or differential settlement.

- Q: How do geogrids improve the load-bearing capacity of soils?

- Geogrids improve the load-bearing capacity of soils by providing reinforcement and stabilizing the soil matrix. When geogrids are installed within a soil mass, they create a strong interlocking system, distributing the applied loads more evenly and reducing the potential for soil movement or settlement. This reinforcement effectively increases the soil's shear strength and overall stability, enabling it to withstand higher loads and improve its load-bearing capacity.

Send your message to us

Fibreglass Geogrids for Asphalt Pavement Reinforcement

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords