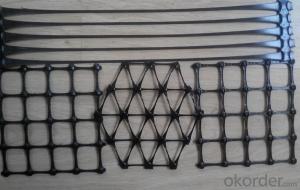

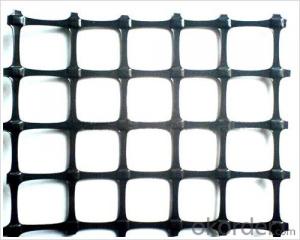

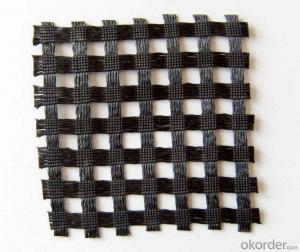

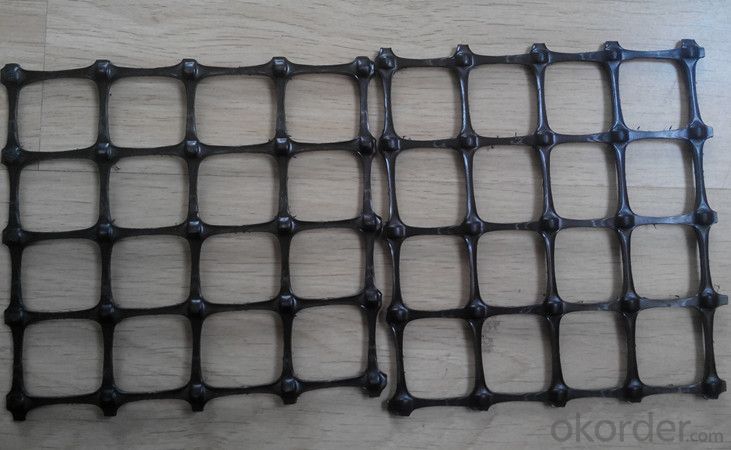

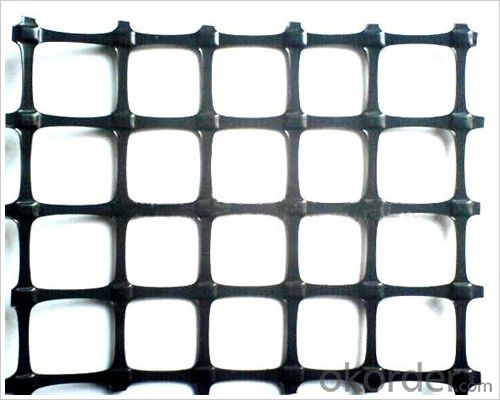

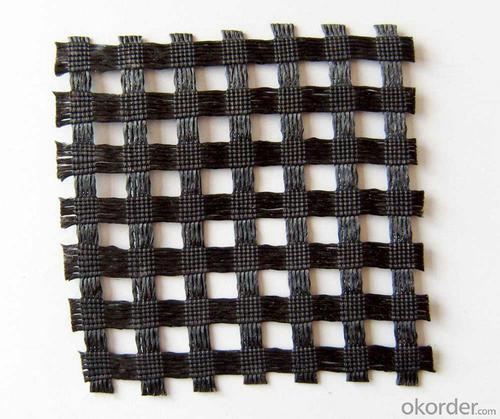

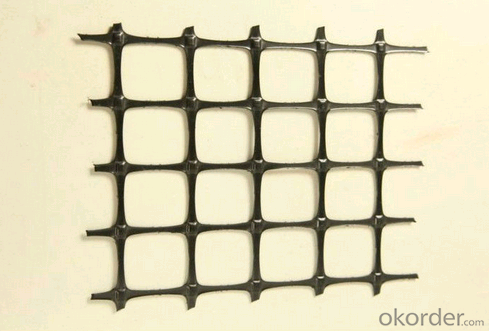

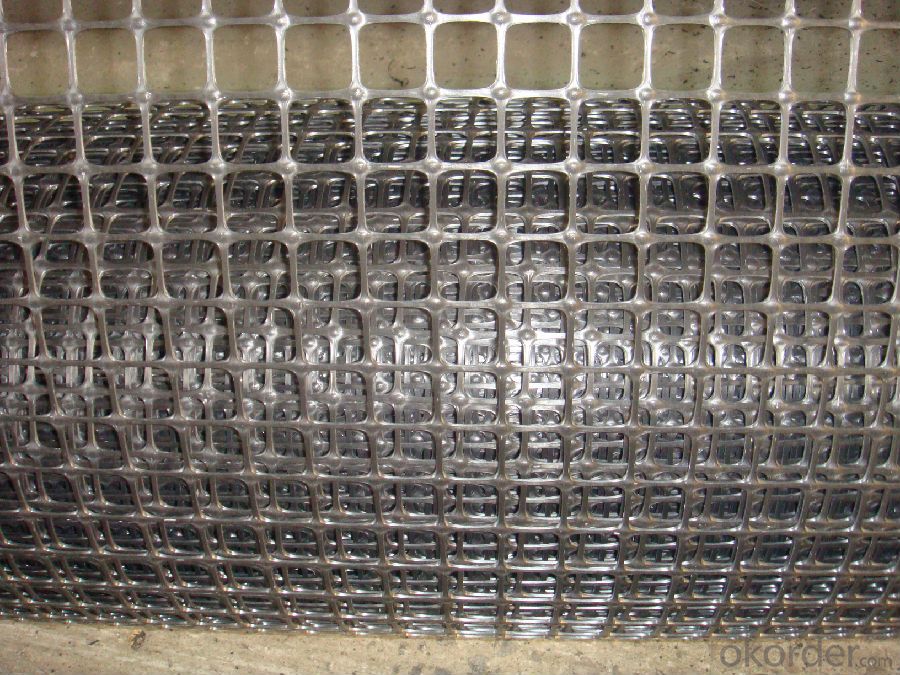

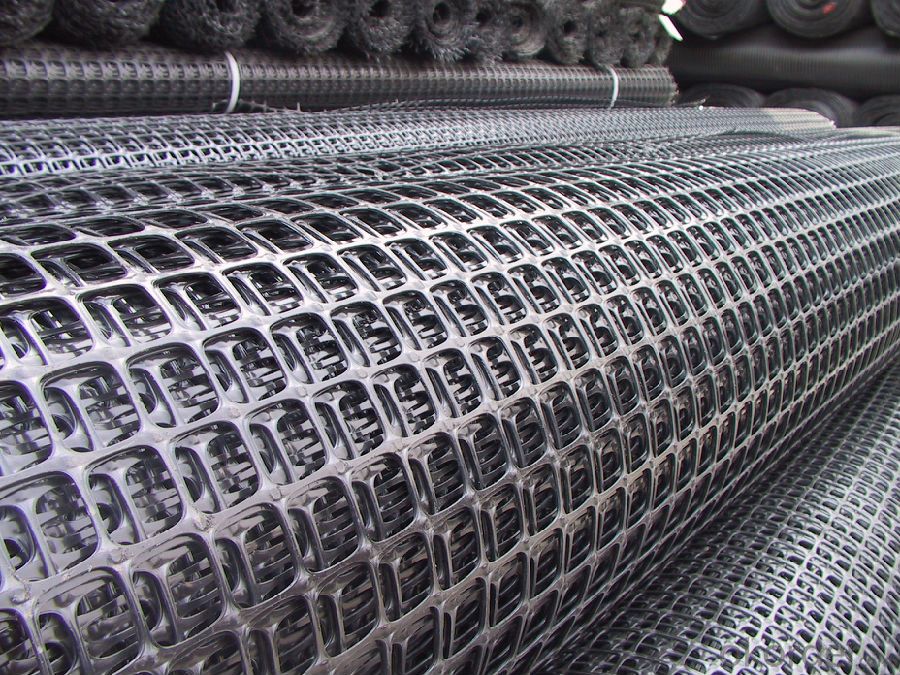

Geogrids for Access Routes - Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Applications:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

| Packaging Details: | according to your need |

| Delivery Detail: | 7days |

FAQ

Q:Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q:What is your minimum order quantity?

A:The minimum order is negotiable.

Q:What is your payment terms?

A: T/T or L/C

Q: What is your delivery time?

A:Production time usually cost 7-15 days.

Q: Why we choose you?

We have up to 15 years experience of geogrid manufacture. best quality of product is guaranteed!

- Q: How much is the tensile strength of Geogrid

- Divided into three categories: the overall plastic stretch: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: How do geogrids enhance the performance of reinforced embankments?

- Geogrids enhance the performance of reinforced embankments by providing a stable and strong reinforcement layer. They distribute and transfer loads more efficiently, reducing lateral spreading and settlement. Geogrids also increase the overall stability of the embankment, preventing erosion and maintaining its integrity over time.

- Q: Physical characteristics of geogrid construction method

- 2, check the geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.3, one-way geogrid for reinforcing the dam and road slope and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse phenomenon, at the same time with a gentle slope, covers an area of large, retaining wall have the same problem with Geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.4, one-way geogrid to reinforce the River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period.5, one-way geogrid for processing landfills: Geogrid and other synthetic materials using a combination of Soil Treatment Landfill, can effectively solve the problem of gas emissions derived from the uneven settlement of foundation, and can improve the landfill to maximize storage capacity.6, one-way geogrid special purpose: low temperature resistance. Low temperature resistance of geogrid Lianyi, at - 45 C and 50 C - repeated 200 cycles, the performance indexes meet the requirements, and has been applied to the test of the Qinghai Tibet railway, the North less ice permafrost and ice rich permafrost and ice rich permafrost bad geology.

- Q: Are geogrids resistant to aging?

- Yes, geogrids are generally resistant to aging. They are designed to withstand long-term exposure to environmental factors such as UV radiation, temperature fluctuations, and chemical exposure, which helps to maintain their strength and durability over time.

- Q: Can geogrids be used in retaining walls for highway projects?

- Yes, geogrids can be used in retaining walls for highway projects. Geogrids are commonly used in such projects to reinforce soil and provide stability to the retaining walls. They enhance the overall strength and durability of the walls, making them a reliable choice for highway construction.

- Q: How do geogrids help in preventing differential settlement?

- Geogrids help in preventing differential settlement by providing reinforcement to the soil, increasing its strength and stability. They distribute the loads more evenly, reducing the differential settlement by minimizing the differential movements between different sections of the soil.

- Q: Are geogrids suitable for railway track stabilization?

- Yes, geogrids are suitable for railway track stabilization. Geogrids provide effective reinforcement and stabilization to the track structure, improving its durability and resistance to deformation caused by heavy train loads. They enhance the load-bearing capacity of the track and prevent the formation of track deformations such as rutting and settlement. Moreover, geogrids help in distributing the load more evenly, reducing the stress on the underlying soil and improving overall track performance.

- Q: How do geogrids improve the performance of geotextile-reinforced slopes for erosion control?

- Geogrids improve the performance of geotextile-reinforced slopes for erosion control by providing additional strength and stability. They enhance the load-bearing capacity of the geotextile and prevent it from stretching or shifting under pressure. This reinforcement helps to distribute the forces evenly across the slope, reducing the risk of slope failure and erosion. Additionally, geogrids increase the overall longevity and durability of the slope, ensuring long-term erosion control effectiveness.

- Q: What is the profit margin of the production of Geogrid

- If the product is supplied in accordance with the specifications required by the contractor

- Q: Can geogrids be used in bridge abutments and approach embankments?

- Yes, geogrids can be used in bridge abutments and approach embankments. Geogrids are often employed in these structures to enhance soil stability, reinforce the embankment, and provide additional support to the bridge. By distributing loads more evenly and reducing lateral movement, geogrids can help improve the overall performance and longevity of the abutments and embankments.

Send your message to us

Geogrids for Access Routes - Steel Plastic Welding Geogrid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords