Tenax TT High Strength Polyester Geogrid - Shandong Direct Manufacturer for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

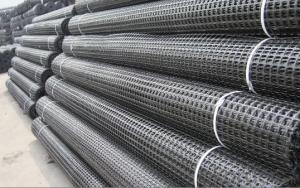

Shandong High Strength Polyester Geogrid Direct Manufacturer for Civil Engineering Use

Specifications of polyester geogrid:

1. High strength, high modulus and low elongation.

2. Aging resistance and high tensile strength.

3. Pre-designed.

High Strength Polyester Geogrid Direct Manufacturer for Civil Engineering Use

Introduction of polyester geogrid:

High strength polyester warp-knitting geogrid adopts high strength, high modulus, and low shrinkage twisting industrial polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending among warp and weft direction. Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction. Then it forms into mesh size product after coated with high quality water-soluble PVC which improves its strength, various technical standards and gives full play of its mechanical property.

High Strength Polyester Geogrid Direct Manufacturer for Civil Engineering Use

Product Features of polyester geogrid:

1. High strength, high modulus and low elongation.

2. Aging resistance and high tensile strength.

3. Pre-designed and easily combing with gravel and soil.

High Strength Polyester Geogrid Direct Manufacturer for Civil Engineering Use

Application of polyester geogrid:

1. Strengthening soft roadbed of high-class roads and high speed railways, separating different subgrade soil material.

2. Using in reclamation engineering, dam, landslides and retaining wall.

3. Enhancing various roadbeds.

4. Strengthening soft roadbed of airport.

High Strength Polyester Geogrid Direct Manufacturer for Civil Engineering Use

Package and Delivery of polyester geogrid:

1. each roll with two woven bags; or by pallet

2. Delivery time is about 15-20days after deposit received

- Q: Can geogrids be used in soil stabilization for sports fields?

- Yes, geogrids can be used in soil stabilization for sports fields. Geogrids are commonly used to reinforce soil, increase its strength and stability, and prevent erosion. They can help distribute loads and minimize soil movement, making them suitable for sports fields that experience heavy foot traffic and require a stable playing surface.

- Q: Can geogrids be used for reinforcement in soft soils?

- Yes, geogrids can be used for reinforcement in soft soils. Geogrids are commonly used in geotechnical engineering to improve the stability and strength of soft soils. They provide additional tensile strength and distribute loads more evenly, reducing settlement and improving overall performance in soft soil conditions.

- Q: Can geogrids be used in reinforcement of reinforced soil slopes?

- Yes, geogrids can be used in the reinforcement of reinforced soil slopes. Geogrids are commonly used in geotechnical engineering applications to enhance the stability and performance of soil structures, including reinforced soil slopes. They are typically placed within the soil mass to provide tensile strength and improve the overall resistance to soil movement. By effectively distributing and restraining the forces exerted on the soil slope, geogrids can significantly enhance its stability and prevent potential failures.

- Q: How do geogrids improve the bearing capacity of foundations?

- Geogrids improve the bearing capacity of foundations by providing reinforcement and stability to the soil. They act as a strong tensile element, distributing the load more evenly and reducing settlement. This helps to prevent soil movement and failure, ultimately increasing the overall strength and stability of the foundation.

- Q: Are geogrids suitable for reinforcement of steep slopes?

- Yes, geogrids are suitable for reinforcement of steep slopes. Geogrids are high-strength materials that can be used to stabilize slopes and prevent erosion by providing mechanical reinforcement. They are effective in increasing the stability and load-bearing capacity of steep slopes, making them an ideal solution for slope reinforcement projects.

- Q: What is the meaning of the geogrid reinforced asphalt in the project list

- Paving the asphalt before putting a layer of Geogrid

- Q: Can geogrids be used in railway construction?

- Yes, geogrids can be used in railway construction. Geogrids are commonly used to reinforce and stabilize the railway track substructure, providing improved load distribution and preventing soil movement. They help to increase the overall strength and stability of the track, making it more resistant to deformation and settlement. Additionally, geogrids can help reduce the maintenance needs of the railway infrastructure, making them a beneficial solution for railway construction projects.

- Q: Can geogrids be used in stormwater management applications?

- Yes, geogrids can be used in stormwater management applications. Geogrids are often used to reinforce and stabilize soil in various construction projects, including stormwater management systems. They help to improve the strength and stability of the soil, allowing it to better withstand the forces and pressures exerted by stormwater. Additionally, geogrids can also enhance the performance of stormwater management structures by preventing soil erosion and promoting water infiltration. Overall, geogrids are a valuable tool in stormwater management applications.

- Q: Glass fiber grating with large pulling force for Expressway

- To improve the overall use of polyester geogrid using high strength nylon fiber filament, warp knitting mesh fabric.

- Q: What are the advantages of using geogrids in ground improvement for slope stabilization?

- Geogrids offer several advantages when used in ground improvement for slope stabilization. Firstly, they enhance the tensile strength of the soil, providing reinforcement against slope movement and potential failure. Secondly, geogrids distribute the load more evenly, reducing stress concentrations and preventing localized failures. Additionally, these materials are easy to install and cost-effective, making them a practical solution for stabilizing slopes. They also allow for better drainage, reducing the risk of water accumulation and associated erosion. Overall, geogrids provide a reliable and efficient method for enhancing slope stability and reducing the risk of slope failure.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1987 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tenax TT High Strength Polyester Geogrid - Shandong Direct Manufacturer for Civil Engineering Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords