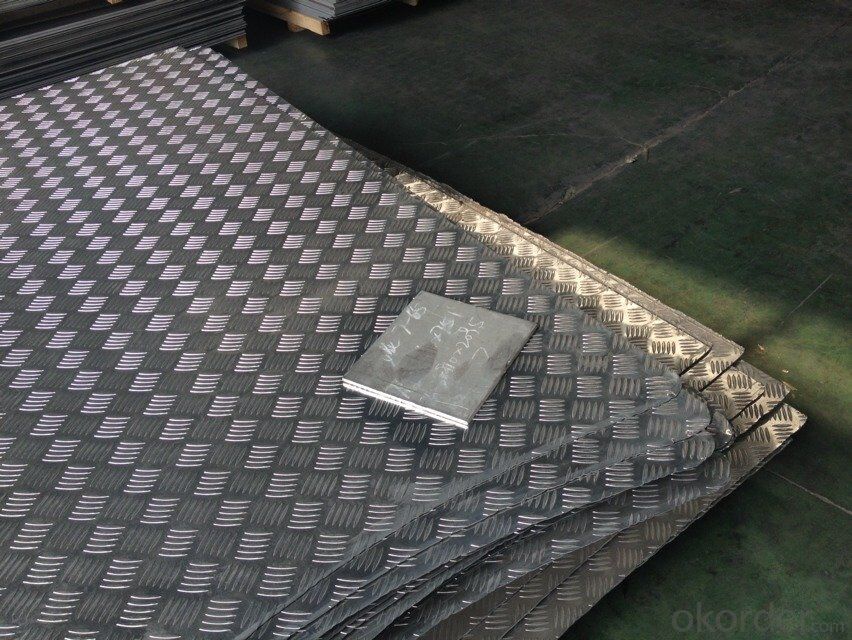

12 Ft Long Brown Aluminum Sheets - Mirror /6k/8k Surface Finish 5052 H34 Aluminum Sheet / Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Are aluminum sheets suitable for chemical reactors?

- Yes, aluminum sheets are suitable for chemical reactors as they possess excellent corrosion resistance, high thermal conductivity, and are lightweight, making them ideal for various chemical reactions.

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: Can the aluminum sheets be used for manufacturing automotive wheels?

- Indeed, automotive wheels can be manufactured using aluminum sheets. As a lightweight and sturdy substance, aluminum is widely employed in the automotive sector owing to its remarkable strength-to-weight ratio. The malleability and machinability of aluminum sheets allow them to be shaped and processed according to the specific requirements and desired form of automotive wheels. Moreover, aluminum boasts exceptional resistance to corrosion, making it highly advantageous for automotive wheels that encounter diverse weather conditions and road debris. In summary, aluminum sheets offer a fitting choice for the production of automotive wheels as they offer a harmonious blend of strength, weight, and corrosion resistance.

- Q: For example, now the price of aluminum is 30000 yuan / ton. How much is that 2mm aluminum sheet with 1 square meters? What's the formula?What about the stainless steel plate, iron plate, and galvanized sheet? Can these (yuan / ton) be converted into (yuan / square)?Hurry! Which expert can I help you?!

- Know that the density of aluminum is 2.7 g / cubic centimeter or 2700 kg / cubic meterThen 2mm thick aluminium plate with a weight of 1 square meters is:M= P *v=2700*1*0.002=5.4 (kg)=5.4*10^ (-3) tonsThe price of aluminium is 30000 yuan / ton nowTherefore, the title of the money required should be 30000* (5.4*10^ (-3)) =162 yuanEmpathy,The density of iron is 7.8 KG/M3The density of stainless steel is 7.52-7.75 KG/M3The same is true of galvanized sheets, as long as the density is known

- Q: Are aluminum sheets suitable for construction applications?

- Yes, aluminum sheets are suitable for construction applications. Aluminum is a lightweight and durable material that offers several advantages in construction projects. It has high strength-to-weight ratio, making it easy to handle and transport while still providing excellent structural integrity. Aluminum sheets are corrosion-resistant, which makes them ideal for outdoor applications. They can withstand exposure to harsh weather conditions, such as rain, snow, and UV rays, without deteriorating or rusting. This resistance to corrosion ensures the longevity of the construction project. In addition, aluminum sheets are highly malleable and can be easily shaped and formed into various sizes and designs. This versatility allows architects and designers to create unique and aesthetically pleasing structures. Aluminum sheets can be used for roofing, siding, cladding, and façade systems, as well as in the construction of windows, doors, and curtain walls. Moreover, aluminum is a sustainable material, as it is 100% recyclable and requires significantly less energy to recycle compared to other metals. This makes aluminum sheets a more environmentally friendly choice for construction projects. In summary, aluminum sheets are suitable for construction applications due to their lightweight, durability, corrosion resistance, malleability, and sustainability. Their versatility and aesthetic appeal make them an excellent choice for a wide range of construction projects.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Yes, aluminum sheets can be an alternative to glass in certain applications. Aluminum is lightweight, durable, and has excellent corrosion resistance, making it suitable for outdoor and industrial applications where glass may be prone to breakage or damage. Additionally, aluminum sheets can provide better insulation and soundproofing properties compared to glass. However, it is important to consider specific requirements and limitations of each application before choosing aluminum sheets as an alternative to glass.

- Q: According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- it particularly is authentic that many deodorants, quite those categorized anti-perspirants, incorporate aluminum chloride as an lively ingredient. Aluminum chloride does decrease sweat production via the sweat glands that are placed interior the floor and are quite ample under the hands. For some people who're heavy sweaters this drying consequence is amazingly significant. despite the fact that those deodorants decrease sweat production they do no longer block the sweat glands. we are no longer attentive to any at as quickly as risky outcomes on maximum persons from making use of a deodorant containing aluminum chloride. In our very close society at present, physique hygiene and prevention of physique smell are significant. in case you do no longer use a deodorant you are able to discover your persons the two complaining or keeping off you. while you're worried with reference to the drying consequence seem for a deodorant that would not incorporate aluminum chloride.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Yes, aluminum sheet can be used for electrical grounding applications. Aluminum is a highly conductive material, making it suitable for use in grounding systems. It is often used in various electrical applications due to its low resistance and excellent electrical conductivity. Aluminum sheet can effectively carry electrical current and safely dissipate it into the ground, ensuring the protection of electrical systems and preventing electrical hazards. Additionally, aluminum's lightweight and corrosion-resistant properties make it a preferred choice for grounding applications in various industries, including construction, automotive, and aerospace.

Send your message to us

12 Ft Long Brown Aluminum Sheets - Mirror /6k/8k Surface Finish 5052 H34 Aluminum Sheet / Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords