PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement

Product Description of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

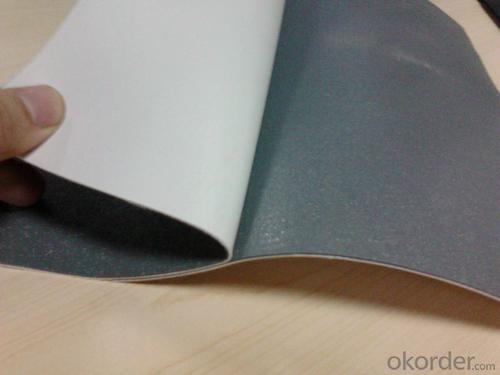

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

1. Excellent anti-aging property.

2. Puncture- resistant.

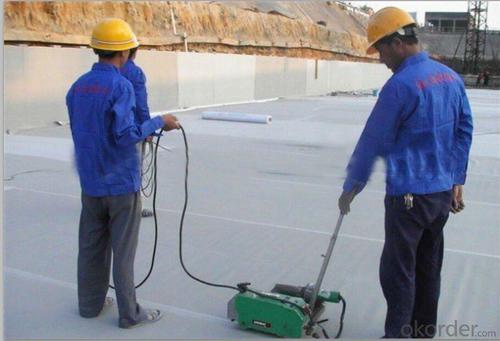

3. Welding construction,

4. High tensile strength, good elongation, good dimensional stability.

5. Good plasticity.

6. It has self-extinguishing from fire property.

7. Materials surface is smooth, fast color, stain resistance.

8. More wide, Wastage become less when being used.

Classification of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Images of PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: APP selection of asphalt waterproofing membrane selection points

- 1, I type polyester tire or glass fiber tire modified asphalt waterproofing membrane PET higher heat resistance, but low temperature flexibility is poor. Suitable for non-cold areas for general construction works of the roof waterproof layer. The waterproofing material of the upper surface material of polyethylene film or fine sand shall not be exposed.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Efflorescence or mineral deposits on surfaces can be prevented with the use of a waterproofing membrane. Efflorescence occurs when water-soluble salts dissolve in concrete or masonry materials and migrate to the surface, leaving behind a white residue. By stopping water from penetrating the surface, a waterproofing membrane reduces the amount of water available to dissolve these salts and carry them to the surface, effectively reducing the occurrence of efflorescence. Similarly, mineral deposits can form when water with dissolved minerals evaporates, leaving behind the minerals as residue. A waterproofing membrane prevents water from reaching the surface, thus minimizing the formation of mineral deposits. It is important to note, however, that a waterproofing membrane may not completely eliminate these issues if there are underlying problems with the material or water source. To ensure the effectiveness of the waterproofing membrane in preventing efflorescence or mineral deposits, regular maintenance and proper installation are crucial.

- Q: SBs waterproof cold sticky how to do?

- 3, the node sealed processing. To be the primary treatment agent after drying, the first outlet, the root of the pipe and other vulnerable parts of the leakage, in the radius of 200mm range, even brush a layer of adhesive, brushing thickness of about 1mm is appropriate. Paste a layer of polyester fiber after the non-woven fabric, and in the non-woven cloth and then brushing a 1mm thick adhesive. After drying to form a layer of sealing layer.

- Q: Can a waterproofing membrane be used on concrete?

- Yes, a waterproofing membrane can be used on concrete. In fact, it is a commonly used method to prevent water penetration and protect concrete structures from moisture damage. A waterproofing membrane is a thin layer of material that is applied on the surface of the concrete to create a barrier against water and moisture. It can be made from various materials such as bitumen, rubberized asphalt, polyurethane, or acrylic. The membrane is typically applied in liquid or sheet form and adheres to the concrete surface to form a continuous and impermeable coating. This coating prevents water from seeping into the concrete, which can cause degradation, cracks, and other forms of damage. Waterproofing membranes are widely used in various concrete applications, including basements, foundations, roofs, and other structures that are exposed to moisture or water.

- Q: Can a waterproofing membrane be used for a basement floor?

- Yes, a waterproofing membrane can be used for a basement floor.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be used for a swimming pool deck?

- Yes, a waterproofing membrane can be used for a swimming pool deck. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting the pool deck from water damage and ensuring its longevity.

- Q: Can a waterproofing membrane be used for roofing?

- Yes, a waterproofing membrane can be used for roofing. In fact, it is a common choice for many roofing applications. Waterproofing membranes are designed to provide a protective barrier against water infiltration, which is essential for preventing leaks and water damage on roofs. These membranes are typically made of durable materials such as asphalt, synthetic rubber, or thermoplastic, which are resistant to water and can withstand harsh weather conditions. They are installed over the roof surface and provide a seamless, watertight layer that helps to keep the interior of the building dry and protected. Additionally, waterproofing membranes can be used on various types of roofs, including flat roofs, sloped roofs, and even green roofs. Overall, using a waterproofing membrane for roofing is an effective way to ensure long-lasting durability and protection against water damage.

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can differ depending on various factors. These factors include the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care given to the membrane. Typically, waterproofing membranes designed for extreme weather conditions can last 20-30 years or more if they are of high quality. These membranes are usually made from durable materials like modified bitumen, PVC, EPDM, or TPO. These materials are specifically engineered to endure harsh weather elements. It is worth noting that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can speed up the deterioration of the membrane. For instance, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. To extend the lifespan of the waterproofing membrane in extreme weather conditions, regular maintenance and inspections are crucial. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better shielded against the harsh effects of extreme weather. Moreover, proper installation techniques and adherence to the manufacturer's guidelines are vital for ensuring the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can significantly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can endure extreme weather conditions for several decades, it is important to regularly monitor its condition, provide proper care and maintenance, and promptly address any issues that arise in order to maximize its lifespan.

- Q: Can a waterproofing membrane be used on precast galvanized surfaces?

- Precast galvanized surfaces can benefit from the use of a waterproofing membrane. This membrane serves as a safeguard against water infiltration and can be applied to various surfaces, including precast galvanized ones. By preventing water from seeping into the surface, the membrane safeguards the underlying structure from moisture damage. However, it is crucial to prepare the precast galvanized surface adequately before applying the membrane. This involves removing any loose or flaking galvanized coating to ensure proper adhesion of the membrane. Furthermore, it is recommended to consult the manufacturer or supplier of the waterproofing membrane to guarantee compatibility with galvanized surfaces and to follow their recommended application guidelines for optimal outcomes.

Send your message to us

PVC Waterproofing Sheets in 1.2mm with Polyester Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords