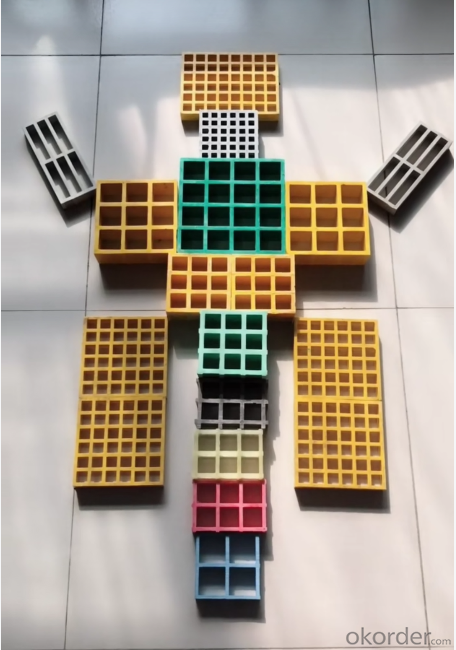

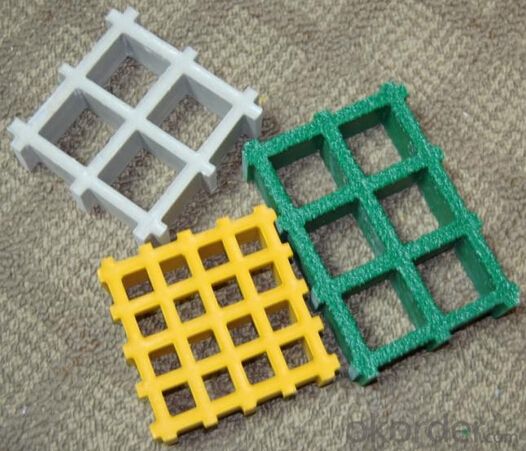

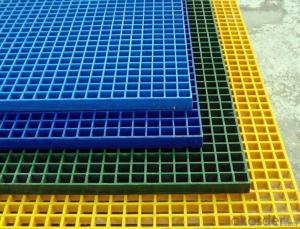

Plastic Sheets FRP Grating for Industry, Workshop, Walkway

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Molded grating is manufactured by laying continuous glass fibers in the mould in the direction of vertical and horizontal, and thoroughly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface. Any process such as post applied grit could be bonded after as a secondary operation.

The size check the following:

Mesh size:38mm*38mm,40mm*40mm,50mm*50mm

panel size:1220mm*3660mm,1000mm*4000mm

>> Industrial areas: such as chemical plants / plating plant operating platform, maintenance platform,photovoltaic power generation platform walkway

>> Sewage treatment areas: sewage treatment plant aisle and sealing cover

>> Municipal Engineering areas: Pedestrian Walkway, Trench / Cable Trench Cover, Tree Grating

>> Marine applications area: Boat decks or bridge materials, Offshore oil platform

>> Other civilian areas: such as car washing, cattle and sheep farms and so on

>>Washing liquid can be used to clean the dust and dirties on the surface, no need of other maintenance measures.

>> Avoid direct connection with naked fire and high temperature, such as electric welding.

>>Avoid the drag and impact damage from any steel, steel sharp tools, and the painting pollution.

Advantage:

1. Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

2. Fire Resistance

Our special formula provide grating with excellent fire resistant performance. Our FRP gratings pass ASTM E-84 Class 1.

3. Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Different thickness and mesh size bring the client more choice.

4. Safety & Anti-slip

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

5. Electrical Insulating

High strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KV/mm. There is no electric spark even when impact by tools, meanwhile it is non-magnetism. FRP Molded Grating could be used safely under the antiknock, diamagnetism and electric-resistance environments.

6. Aging Resistance

The high-grade resin and anti-ageing stabilizer provide grating long-life ageing resistant performance and the unique design make grating excellent self-cleanness function and keep its brightness and strength over a long time. The service life of grating could be 25 years.

Application check the following:

- Q: Under the temp. probe, and under the heater, obv. And these go under the liner, right? Electricity and water together = bad deal!So have I found the right answer?Bed is in chilly room in cold house, soft-sided with wooden frame. Will of course be using woolen, polyester, blankets on top, or maybe put the fake eiderdowns under bottom sheet and use the wool etc. over top sheet. Point is that bed will stay covered with warmth-keepers just about all the time.Am thinking of running the foil up along the side-walls. I intend to tape the sheets together into a complete large sheet.Had planned to use insulating rigid foam but decided was too much work to replace the home-made frame. Am hoping that the foil will reflect heat back into the water, not out into room.Furnace is forced-air, and electric bill in winter is Awful! IMO, at least.

- I doubt aluminum foil has much, if any, R-value, but I'm not an HVAC guy. I do know that pink styrofoam doesn't have much R-value unless you go several inches thick. Maybe try surrounding the bed in about 6 of the styrofoam on all sides. Use HVAC foil tape to seal any seams. Then mask it all in something like tileboard.

- Q: I was wondering if it was possible to run a plastic binder cover (like the kind you use with a comb binding machine) through my printer? I'm not sure if the ink would even actually stick to it... or if it might even melt in my new printer? I have a new Kodak ESP3... so I don't want to mess it up! Anyone know? I know you can buy clear sheets made for the inkjet printers... but I didn't know if these were different... Thanks in advance.

- the binder covers a to slick for the ink to stick to. the overhead clear plastic printable sheets are a bit thin for use as covers. There are Thermal plastic sheets that will take printing...ask some graphic engineer...they use it for overlays on plans.

- Q: How do you paint gouache on a plastic board?

- Water is water soluble, generally in the paper, the plastic plate can not long period of attachment.

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are commonly used as a cost-effective and easy-to-install option for temporary or low-traffic areas. However, it is important to note that plastic sheets may not be as durable or long-lasting as other flooring materials, and their suitability for specific applications should be assessed based on factors such as foot traffic, moisture resistance, and desired aesthetic.

- Q: Gardening tips

- Depending on how tall the plant is... Low lying plants can take the plastic with bricks or rocks holding it down around the plants. If they are taller plants like foot-tall tomato plants (shame on you for planting this early, lol), then the absolute best thing I have found to use is upside down turned plant pots placed over top of the plants (screw into the soil about 1/8th or 1/2 inch deep so that no air gets in around the base. I have also used empty milk jugs with the lids and most of the top cut off. Just set over top of plants and push into soil a little bit. If your plants are too tall already and you don't have any empty containers big enough to comfortably hold the plant inside, most veggie and flower plants can stand a little stress (by cramming them (just LIL bit) into the pot). The right kind of Stress actually makes most plants stronger and more resilient to future stresses and/or diseases. Hope this helps.

- Q: I need to buy one, and I don't know what word to use to search for it in OKorder

- Document folder

- Q: Can plastic sheets be used for agricultural applications?

- Yes, plastic sheets can be used for various agricultural applications. They are commonly used as greenhouse covers, mulch films, and protective barriers to create controlled environments, conserve moisture, prevent weed growth, and protect crops from pests. Plastic sheets are also used for soil solarization, which helps control soil-borne diseases and weed growth.

- Q: In my 8th grade art class my teacher had us do a project that involved contrast. We had to use this type of paper and cut out parts of the white so that the black would show through and there would be contrast between the full white and full black areas. I can't remember the name of it and would like to get some for hobby purposes. It was a black sheet of something that was sort of plastic-like and was somewhat reflexive. Then directly on top of that was a sheet of normal paper stuck to the black sheet. If anyone could tell me the name of this paper that would be great. Also if there are any common stores that I could get it at. Maybe Michaels?

- Maybe its carbon paper

- Q: Are plastic sheets resistant to breakage from heavy objects?

- Yes, plastic sheets are generally resistant to breakage from heavy objects, but it depends on the type and thickness of the plastic being used. Certain types of plastics, such as polycarbonate or acrylic, are known for their high impact resistance and can withstand heavy objects without breaking. However, it is always advisable to choose a plastic sheet with the appropriate thickness and strength for the specific weight and impact it will be subjected to.

- Q: Can the toilet be covered with plastic buckles?

- It is low cost and good decorative effect, so it occupies an important position in the family decoration ceiling materials, and becomes the leading material for the ceiling of toilets, kitchens, balconies and so on. Suspended ceiling is a kind of technique often used in interior design. People's vision often contact with it more time, so the shape of ceiling and artistic treatment have obvious influence on space effect.

Send your message to us

Plastic Sheets FRP Grating for Industry, Workshop, Walkway

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords