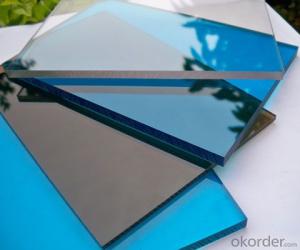

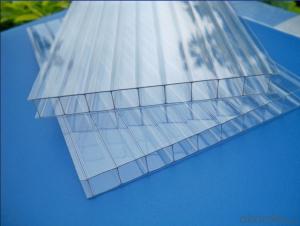

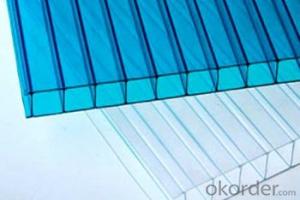

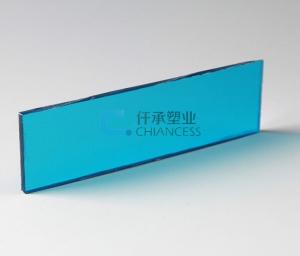

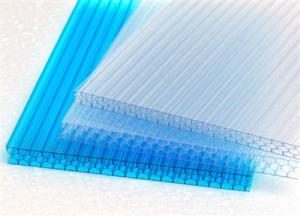

Tinted Polycarbonate Sheet 6mm Polycarbonate Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

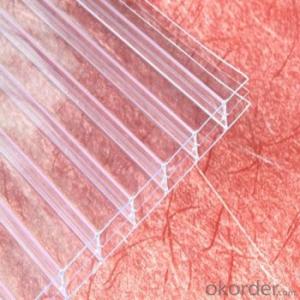

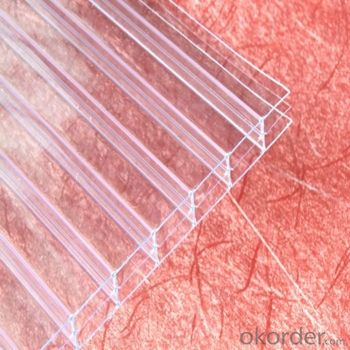

Polycarbonate PC Solid sheet

Product | Thickness | Width | Length | Color |

Solid Sheet | 1.5-20mm | 1.22m | 2.44m, 5.8m, 11.8m, other length can be customized | clear, green, blue, brown, opal, custom |

1.56m | ||||

1.82mm | ||||

2.1m max: 2.3m |

Application of Polycarbonate Sheet

1) Roofing for greenhouse, swimming pool, shopping malls, commercial streets.

2) Sunshade for stadiums and bus stops, gazebo, open air carport.

3) Lighting canopy for corridors, passages and subway entries.

4) ATM machine covers, telephone booth, gateways, garages.

5) Sound and heat insulation wall for expressways and houses.

6) Instead of glass, decoration door, curtain wall.

7) Soundproof material for partitions.

8) Unbreakable material for glazing widows, roof glazing.

9) Lighting of modern villa, rain-proof lighting shed of underground garage entryway.

10) Front wind shields of motorcycles, airplanes, trains, liners, vehicles, motorboats, submarines and riot shields.

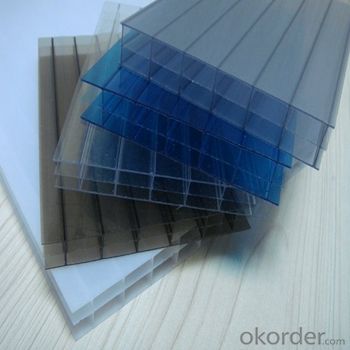

Product Description

Material | 100% virgin bayer or sabic |

Color | Clear, Lake blue, Opal ,green,yellow, ect. |

Thickness | 1.2-15mm |

Max width | 2100mm(can be customized) |

Length | 5800mm,12000mm,11800mm,6000mm or can be customized. |

Warranty | Usually 10 year's quality guarantee which depends on the models you ordered. |

- Q: Which friends know how to remove the plastic film on the sun?

- You can try with a soft cloth or sponge dipped in a neutral soap or detergent scrub the sun surface dust, dirt, and then rinse thoroughly with water, and finally to a soft cloth to dry.

- Q: PE sun panels and PC sun panels are different

- PC temperature some, much better transparency, PE is not temperature, transparency in general. PE price is about twice as low.

- Q: Sunshine board can be used in what areas

- Sunshine board with high transparency, light weight, shock, noise, heat insulation, flame retardant, anti-aging characteristics, is a high-tech, comprehensive performance is extremely remarkable, energy saving and environmental protection plastic sheet, is currently widely used in the world Plastic building materials, other architectural decoration materials (such as glass, plexiglass, etc.) can not match the advantages of widely used in greenhouse / industrial plant, decoration, advertising signs, parking shed, channel lighting poncho residential, commercial lighting sky, Ecological restaurants, sports venues, swimming pools, warehouses lighting roofs, factories, sports venues and sun shelters, greenhouses, aquaculture and flower greenhouses, as well as telephone booths, newsstand, station and other public facilities, highway noise, advertising Decoration field.

- Q: PC board greenhouses pc board generally use thick? What is the price? What about the current market price? Is the sun board a PC board?

- PC board greenhouse greenhouse generally refers to the sun board greenhouse shed, because the greenhouse shed with more use of PC sun panels, compared with the general 8-10MM, the cost of solid PC stamina cheaper than the price is calculated in accordance with ㎡, now The price of the market is about 40 square meters.

- Q: PC Nai Liban and Sunshine board Which domestic manufacturers of the best products?

- A penny of goods, different prices will have different products, not the best, only the most appropriate!

- Q: Can the stencils be made in the bathroom?

- PC particle board characteristics 1, the surface of the plate can reflect the direct light on the plate of direct exposure, after this treatment can reduce the sunlight penetration. 2, the surface of the board can increase the surface area, while increasing the heat, can extend the service life of the plate. 3, the surface of the plate per square meter distribution of 15,000-18000 pieces of anti-diamond-type particles, reflection, refraction effect can enhance the blocking capacity.

- Q: Project sun board price how much

- Shanghai Jie resistant engineering PC sunshine board price is not constant price, but a comprehensive consideration of technical level, sheet performance, then the raw material prices and other costs through the calculation.

- Q: What is the difference between the PC and the PC board?

- Sometimes the particles may be slightly cheaper, because its surface is uneven, with less raw materials so the cost will be low.

- Q: What can I do with my own sunshine board?

- Own balcony sun block rain, balcony sun room, interior partitions can be ah

- Q: What is the difference between the sunboard and the Capron board?

- The difference between the sunboard and the cardboard: Sunshine board is collectively referred to as mainly produced by PC / PET / PMMA / PP material, one of which is sunshine board, also known as pc sunshine board, polycarbonate as the main raw material manufacturing. PC sun panels are commonly used in the international plastic building materials, there are other architectural materials (such as glass, plexiglass, etc.) can not match the advantages of "not broken glass," said. Widely used in greenhouse / industrial plant, decoration, advertising signs, parking shed, channel lighting rain pond residential, commercial lighting sky, exhibition lighting, sports venues, swimming pool, warehouse lighting business, factories, sports venues lighting ceiling and sun shelter, Agricultural greenhouses, aquaculture and flower greenhouses, as well as telephone booths, newsstand, station and other public facilities, highway noise, advertising decoration field.

Send your message to us

Tinted Polycarbonate Sheet 6mm Polycarbonate Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords