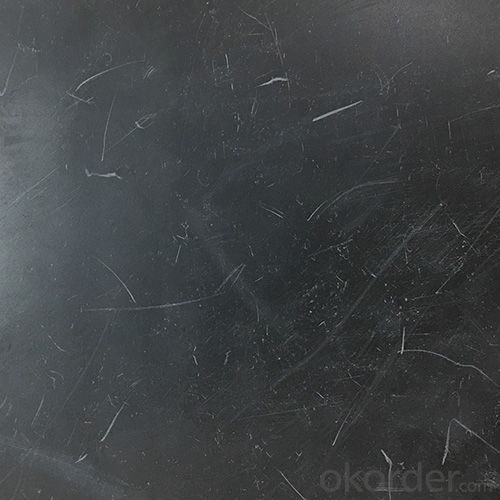

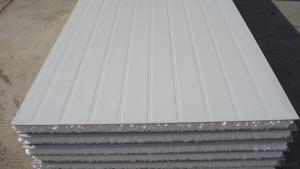

Plastic Sheets - EVA Foam EVA Sheet and EVA Roll for Automotive Interior 3mm Thickness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

EVA foam

Have good flexibility, water resistance, impact resistance

High elasticity, resistance to chemical corrosion, non-toxic

Resistance to abrasion, cut, scratch resistance

Used to realize 100% reproduction cycle, energy saving and environmental protection

Terms & packing

By rolls of eva roll according to customer's indication

FOB Shenzhen or CIF, CFR depending customer's requirements.

Payment term:

30%T/T in advance, balance to be paid against copy of B/L.

Material | EVA Foam |

Density | 139kg/m³ |

Product use | automotive interior, instrument panels, bumpers, medical equipment, household appliances, sports equipment, chidren's toys, youga mat, carpet mats, table mats, shoe etc... |

tensile strength | 0.715mpa |

Thickness | 1mm-106mm |

Size | 1m*2m by sheet As per customers' requirement |

Sample | Available |

elongation at break | 215% |

thermal shrinkage | 6% |

compression permanent deformation | 42% |

Applications

Why Us

Our advantages

• PVC and PU leather manufacturer

• A wide range of top quality PVC, PU leather products available from stock

• Low price and low MOQ (Min.Order Quantity)

• Free samples including the freight

• Short delivery time, up to 15 days

• Long standing reputation with excellent service

Unique Selling Points

· strength, durability, resistance to damage

· lightness, flexibility

· ease of assembly and forming

· increased resistance to UV rays

· high air and water vapour permeability

· resistance to changes in weather conditions and temperature

· produced from the highest quality materials

· a wide range of thicknesses available

· versatility of applications

· very large range of colours

· competitive price.

Other Questions:

Question 1: What Information Should I Let You Know if I Want to Get a Quotation?

A.If you want our factory's design,pls advise the item No.or show me the pictures;

B.If you want to customize,please advise the size of the product (mainly thickness),If it is possible, pls also provide with pictures or design sketch for reference. Samples will be best for clarifying.

Question 2: Are You a Manufactory or Trade Company?

We are a professional manufacturer and exporter specializing in needle punch nowoven fabric for 8 years with 60 acres workshop area. More than 100 professional workers and advanced equipment can make sure the high quality.

Question 3: Where Is Your Factory Located? How can I Visit There?

Our factory located in the Largest Industrial Park in Jiangxi - Nanchang Xiaolan Industrial Park with convenient transportation and beautiful environment covering 60 acres.We can pick you up from Changbei airport to our factory and it takes about 1 hour by car. Warmly welcome you to visit our factory!

Question 4: How Many Days Will Samples Be Finished? How about The Mass Production?

We are honored to offer our existing free samples to be evaluated, the customer only pay for the international express fee.

Sample lead time: 2 days after confirm the artwork

Production lead time: 10-15days after payment

Question 5: When Can I Get the Price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your mail so that we will give priority to your inquiry.

Question 6: Can You do OEM or ODM Orders?

Yes, with 8 years of OEM & ODM experience, we will be extremely happy to offer OEM & ODM service. Warmly welcome your orderings!

Question 7: What about Your Payment Term?

We accept T/T, and others can be dicussed.As a rule, we ask for 50% deposit, and 50% balance before the shipping.

- Q: Trying to make a solar cooker and I'm wondering if glass would work better than plastic sheets to keep the heat in. Well?

- Yes A double pane glass could work even better, the gap insulates and helps retain heat. Note that double pane glass is sealed so you would have to work with the size you get. It also may have a coating inside that lets heat (infrared light) pass one way easier than the other. One way would keep heat inside in cold climates or reversed would help keep heat out in hot climates.

- Q: Are plastic sheets resistant to discoloration from sun exposure?

- Yes, plastic sheets are generally resistant to discoloration from sun exposure.

- Q: Brand new Compaq Laptop has a plastic cover sheet on its top. I want to keep protecting the frame and would like to know if I can get a new sheet in case the original one falls. Is there a way? Thanks,

- you can find the at best buy and circuit city.

- Q: Do plastic sheets require special cleaning or maintenance?

- Yes, plastic sheets do require special cleaning and maintenance. They should be cleaned regularly with a mild soap and water solution, avoiding harsh chemicals that can damage the plastic. It is also important to avoid using abrasive materials while cleaning to prevent scratching. Additionally, plastic sheets should be stored in a cool and dry place to prevent warping or discoloration.

- Q: How can the stains on the plastic steam plate be removed?

- Secret weapon: quick cleaning plastic chopping board 84 disinfectant.Step 1 cleaning with water, diluted 84 disinfectant, usually a bowl of water poured into a small bottle can, according to the number of cleaning items can also adapt to put a little more.

- Q: im trying to make a plexiglass longboard skateboard out of plexiglass

- I would recommend using a polycarbonate like Lexan or Hyzod instead of acrylic resin products like Plexiglas. They are considerably stronger, yet easier to work with. I think a 3/4 inch thickness would be lots if you went with Lexan, but at 4 feet long, any plastic sheet is going to be bouncy (Plexi will snap). You might have to edge it with something rigid to fix that. Usually anything over 1/4 inch (~6mm) is special order, but you never know, a local sign shop or glass shop might have some cutoff for you.

- Q: Would you please help me find clear, acetate sheets that are heat resistant and thick enough to be a card rather than just overlay a card?

- Definitely an art / craft supply shop would be a good starting point. Alternatively, you could try and research on the internet to find a shop which sells what you are seeking.

- Q: What kind of material is the GREE board? It looks like plastic, much harder than plastic

- The wear resistance of the acrylic plate is close to that of the aluminum, and the corrosion resistance of the resistant material is different

- Q: Can plastic sheets be used for outdoor signs?

- Yes, plastic sheets can be used for outdoor signs. They are durable, weather-resistant, and can withstand exposure to sunlight, rain, and other environmental elements. Plastic sheets such as PVC and acrylic are commonly used for outdoor signage due to their versatility and long-lasting properties.

- Q: Do plastic sheets have any fire-resistant properties?

- Yes, plastic sheets can have fire-resistant properties depending on their composition and additives. Some plastic sheets are manufactured with flame retardant additives that slow down the spread of fire and reduce the release of toxic gases. However, it is important to note that not all plastic sheets are inherently fire-resistant and selecting appropriate materials for specific applications is crucial.

Send your message to us

Plastic Sheets - EVA Foam EVA Sheet and EVA Roll for Automotive Interior 3mm Thickness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords