Plastic Sheets - Two Ton Fortified Multi-Wall Polycarbonate Sheet with UV Protection

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000KGS kg

- Supply Capability:

- 200,000KGS kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

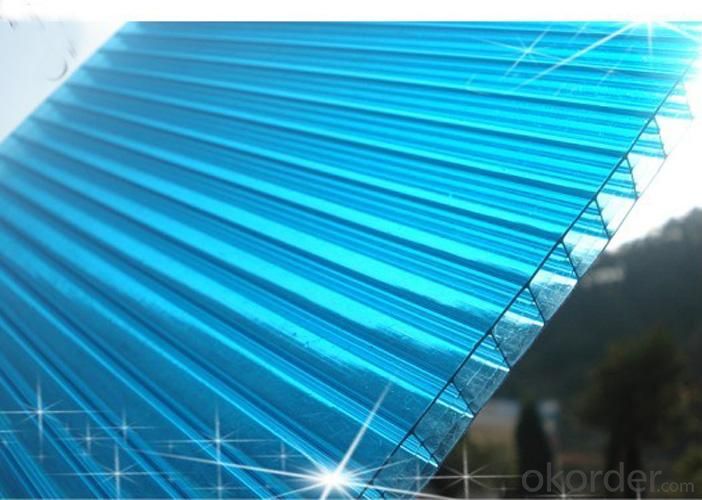

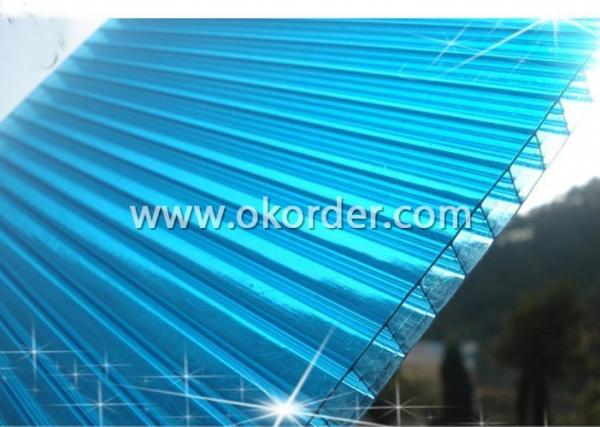

Specifications of Two-tone Fortified Multi-wall Polycarbonate Sheet With UV Protection And Different Colors

1 100% virgin Bayer material

2 Size : Length : 5800mm,11800mm ; Maximun width : 2100mm ; size can as customer requirement

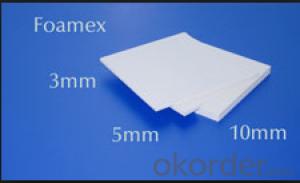

3 Thickness: 4mm-16mm

4 Color: clear, green, blue , light blue , brown , opal , red , yellow and so on.

5 UV protection(One side or two sides)

6 Warranty time:10 year

7 Payment : T/T , LC

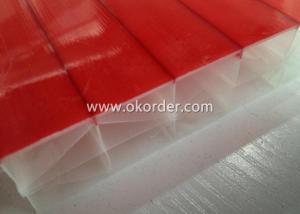

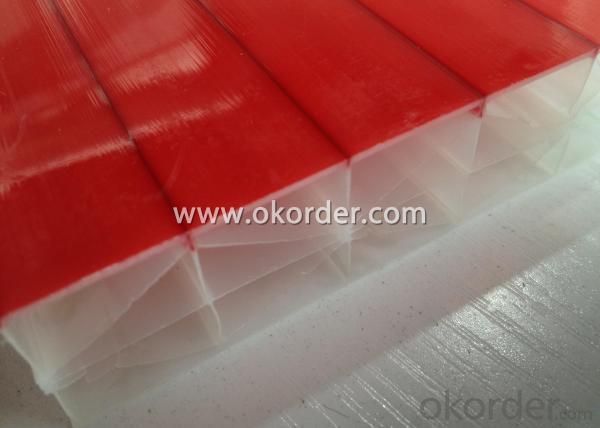

8 Package: Double sides are with PE films

9 Delivery time:25-30 days for 1*40FCL

Features of Two-tone Fortified Multi-wall Polycarbonate Sheet With UV Protection And Different Colors

1 Light weight

2 Very high impact strength

3 Good light transmission

4 Good weather resistance and UV protection

5 High heat insulation

6 Simply processed and installed

7 UV protection layer: 50um

8 Soften temperature : 148°C

9 Continuous use temperature :-40 ~120°C'

Applications of Two-tone Fortified Multi-wall Polycarbonate Sheet With UV Protection And Different Colors

1 Roofing light sheet and sunshade for office building, department store, hotel, stadium, school, amusement center, hospital, ect.

2 Skylight, lighting for corridors, balcony, passages and subway entries, walkways.

3 Do-It-Yourself (DIY), awning, canopy.

4 Advertising lamp boxes, sign board.

5 Anti-riot shield, bullet resistant material, Bank ATMs.

6 Conservatories, agricultural greenhouses, zoos, botanical gardens.

7 Industrial Roofing and Glazing

8 Swimming Pools roofing/cover/sheet

Pictures of Two-tone Fortified Multi-wall Polycarbonate Sheet With UV Protection And Different Colors

- Q: I was wondering if there were any places that you could purchase sheets of clear plastic board with about .5-1mm thickness, and if you can, how can it be cut down? I need a piece that is approximately 60x60 cm, would they even sell sheets large enough to cover this size? Any help or insight would be greatly appreciated.

- Sounds like you are looking for plexiglass. They have it at the big hardware stores. There is a special tool kind of like a box cutter that you can use to cut it yourself, or they will cut. You could certainly get one 60x60cm.

- Q: I'm looking for a custom plastic covering that repels water and covers a safe (1mX 1m)P.S SHIPS TO CANADA

- Go to a place which makes covers for boats, or awnings and tents. Look in your yellow pages under upholstery. A place that sells foam for cushions and bedding may also do this kind of work.

- Q: Can plastic sheets be used for safety windows?

- Yes, plastic sheets can be used for safety windows.

- Q: Can plastic sheets be used for medical purposes?

- Yes, plastic sheets can be used for medical purposes. They are commonly used as barriers for infection control, wound dressings, and protective coverings for medical equipment. Additionally, plastic sheets are also used in the manufacturing of medical devices and disposables.

- Q: With what glue can you stick glass and plastic board firmly?

- Room temperature (25 DEG C) the adherend processing clean, then the material mixed with the ratio of 1:1 with visual glue and B glue coated A after 3 minutes to be coated on the surface of the adhesive, fixed 5-10 minutes positioning.

- Q: Does anyone use rubber or plastic sheet on bed?

- A few of my friends that wet the bed sometimes use one under their sheets. It's no biggie and nothing to worry about if you wet the bed, and the rubber sheet does make clean up easier. Kindest thoughts, Hermes

- Q: Can plastic sheets be used for greenhouse walls?

- Yes, plastic sheets can be used for greenhouse walls. They are commonly used due to their affordability, ease of installation, and ability to allow sunlight to pass through while providing insulation. Additionally, they are lightweight, durable, and can withstand various weather conditions.

- Q: PVC how dirty is the plastic board? Can it be cleaned soon?

- Wash with toothpaste and toothbrushBecause it is not a big object, you can simply brush with toothpaste and then wipe it gently until you wipe it. This adds flavor to the purse.

- Q: Are plastic sheets flammable?

- Yes, plastic sheets can be flammable. The flammability of plastic sheets depends on the type of plastic used and its composition. Some plastics are more flammable than others, and if exposed to high heat or an open flame, they can ignite and burn.

- Q: Can plastic sheets be used for automotive windshields?

- No, plastic sheets cannot be used for automotive windshields. Automotive windshields are typically made of laminated glass, which provides the necessary strength and safety features required for a windshield.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2003 |

| Annual Output Value | US$ 20 Million |

| Main Markets | 15.00% Africa 15.00% South America 10.00% South Asia 10.00% Southeast Asia 8.00% Western Europe 8.00% Eastern Asia 8.00% Mid East 8.00% Eastern Europe 8.00% North America 5.00% Central America 5.00% Oceania |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;ISO 14001:2004; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo; Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 18000.00m2 |

| No. of Production Lines | Above 13 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Plastic Sheets - Two Ton Fortified Multi-Wall Polycarbonate Sheet with UV Protection

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000KGS kg

- Supply Capability:

- 200,000KGS kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords