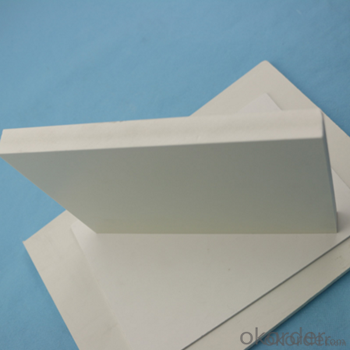

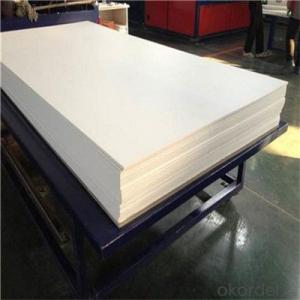

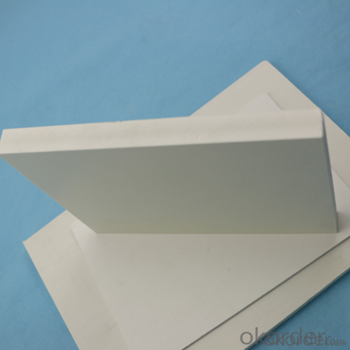

Plastic Sheets - PVC Sheet White 5mm / PVC Foam Sheet Outdoor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

What PVC foam boards can do?

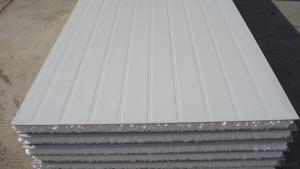

They are wildly used in furniture making,decoration,advertisement,construction and other fields.

such as:

1).Exhibition cabinet, shelf in supermarket

2).Advertisement board and sign board

3).the advertisement sheet for printing, engraving, cutting, sawing

4).Architectural decoration and upholstery

5).Decoration for partition wall and shopwindows

6).Furniture:cabinet,desk,chair,wardorbe,shoecase,window,door

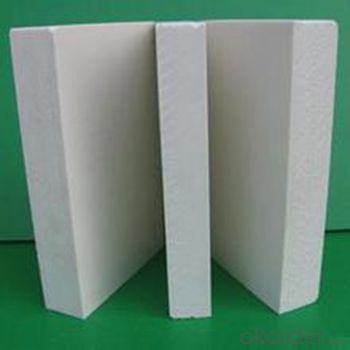

Performace of material

1. The product has the same processing performance, can nail, drilling, cutting, bonding, with a nail or bolt connection fixation, smooth surface, no need to sanding and paint, the paint adhesion also according to individual be fond of painting.

2.Better than wood dimensional stability,can be coated or composite colorant surface can be made of brilliant color, so no need to timely maintenance.

3. A variety of specifications, size, shape and thickness of the demand, which also includes a variety of design, color and grain products, provide more choices to customers.

4.The product is fireproof, waterproof, corrosion, resistant to moisture, not moth eaten, non-toxic, no pollution and other excellent performance, low maintenance cost

5 The use of products have similar wooden appearance, high hardness than plastic, long life, thermoplastic molding, high strength, saving energy

6.Light weight, heat preservation, smooth surface, no formaldehyde and other harmful substances, no poison, no pollution

Surface: printing color, can be coated or made of a variety of colors, with flame retardant, moisture, acid and alkali, long life, high strength, non-toxic, anti-aging ability, can be hot forming and so on;

Appearance: feel to elegant, comfortable feeling and nail, drill, planer, riveting, stick etc., easy to manufacture, with wood processing performance;

Environment protection: it is of great significance to save precious forest resources, save energy, protect the ecological environment and promote the sustainable development of human society.

Application: the advertising industry board, signs, decoration, furniture making, water and underground engineering, construction, packaging materials and containers such as containers and other packaging. In addition, it can be used in the interior decoration of automobiles, trains, subways, ships and aircraft industries.

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

- Q: Can plastic sheets be cut or shaped easily?

- Yes, plastic sheets can be cut or shaped easily using various tools and techniques such as saws, knives, laser cutting, or thermoforming methods.

- Q: Are plastic sheets suitable for outdoor furniture?

- Plastic sheets are generally suitable for outdoor furniture due to their durability, weather resistance, and ease of maintenance.

- Q: Are plastic sheets heat resistant?

- Yes, plastic sheets can be heat resistant depending on the type of plastic used. Some plastic sheets, such as polycarbonate or acrylic, have high heat resistance and can withstand moderate to high temperatures without melting or deforming. However, it is important to note that not all plastic sheets are heat resistant, and some may melt or warp under high temperatures.

- Q: Are plastic sheets resistant to yellowing or discoloration over time?

- Yes, plastic sheets are generally resistant to yellowing or discoloration over time.

- Q: Any type will do but I am primarily looking for the LG Versa phone.

- there are many places you can find screen protectors . you could check at wallmart or fye they usally have them . you could also look on OKorder they have everything! hope this helped...

- Q: What's the best glue for a plastic plate?

- Plastic board: plastic board is made of plastic, and plastic is synthetic macromolecule compound. It can change the shape of the body freely. The plastic is made of synthetic or condensation polymerization with monomer raw materials, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives, it is the main component of synthetic resin.

- Q: They smelled a little different than the surrounding fir and spruce trees but was still kind of a natural odor. The cardboard sheets were also wrapped in the white plastic lattice. Maybe they're something the forestry service uses? But for what??

- and you didn't eat a piece see if you would enjoy your trip? maybe it was a geocache

- Q: I have a 30 gallon plastic bucket that I cut a large square out of it and I have molded the acrylic sheet to the right shape, but is there anyway I can bond the acrylic to the plastic? It needs to be water proof and not leech any chemicals. It will be filled up with water and will hold some fish.

- All the plastic buckets I've seen so far are from PA, PP or PE - plastics chosen for their chemical inertness, which in turn also means that they're d*mn near impossible to glue (pretreatment with hot concentrated nitric acid is among the more accessible methods....). As is acrylic, btw. You might be able to weld them (chemically or thermally), but I wouldn't trust this weld if I did it for the life of the fish. If the overlapping area is large enough and the acrylic sheet goes on the inside of the bucket (so that the water pressure actually compresses the seam), you might try fish tank silicone. It won't really glue the parts together, but might stick well enough (probably until someone tries to poke it :-( ). But I doubt that you'll get that stuff in oe of the big box stores - ordinary builder's silicone or bathroom silicone are no good - they'll leach acetic acid and, in case of bathroom silicone, fungicides.

- Q: About a metre square, by about 7mm thick.

- You would have to visit your local DIY/hardware or glass/window store to find out. Prices can vary area to area based on how much they have to pay the local wholesaler who sells to them. Acrylic is not cheap, it is expensive stuff. Good luck.

- Q: Are plastic sheets resistant to fading?

- Yes, plastic sheets are generally resistant to fading.

Send your message to us

Plastic Sheets - PVC Sheet White 5mm / PVC Foam Sheet Outdoor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords