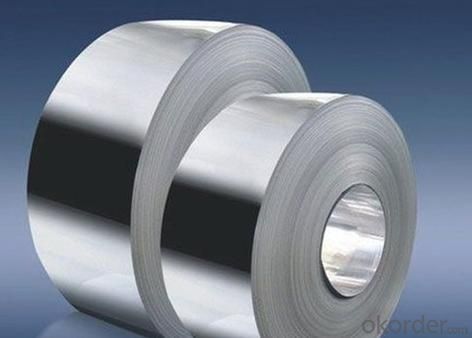

304 Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Strips

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.08 |

max1.00 |

max2.00 |

max0.045 |

max0.03 |

8.00-10.50 |

18.00-20.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥ 205 |

≥ 520 |

≥ 40 |

≤ 200 |

≤ 90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 18-600mm

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q: Can stainless steel wire hooks be used for hanging heavy objects?

- Yes, stainless steel wire hooks can be used for hanging heavy objects. Stainless steel is known for its strength and durability, making it suitable for supporting heavy loads.

- Q: Several ways of drawing stainless steel wire drawing.

- Change the wire diameter stainless steel brush, can obtain different thickness lines. Intermittent thread processing in general brush machine or satsumon machine system. By the principle: the two groups of the same to the differential wheel rotation, group for grinding roller fast rotating rollers, slow rotation of the aluminum group, or Aluminum Alloy plate from the two groups in the roller, brush out the delicate straight lines. Intermittent chaotic pattern drawing is in high speed wire brush, make a no rules, no obvious grain Matt silk pattern aluminum plate to move around the friction. This processing, surface requirements of aluminum or Aluminum Alloy plate the higher. In general corrugated brushing machine or machine by using satsumon. The grinding roller axial movement on the surface of the aluminum group, or Aluminum Alloy plate grinding brush, draw the wavy lines. Also known as optical rotation pattern is used, the cylindrical felt or nylon wheel installed in the gangue drilling machine, polishing with kerosene and ointment, A strip of thread obtained by rotating grinding on the surface of an aluminum or aluminum alloy plate. It is used in ornamental processes for round signs and small decorative dials

- Q: Is stainless steel wire resistant to intergranular corrosion?

- Yes, stainless steel wire is generally resistant to intergranular corrosion. This is because stainless steel contains chromium, which forms a passive oxide layer on the surface of the metal. This oxide layer acts as a protective barrier, preventing the penetration of corrosive agents and thus reducing the risk of intergranular corrosion. However, it is important to note that the resistance to intergranular corrosion can vary depending on the specific grade and composition of the stainless steel wire. Some grades of stainless steel, such as the low carbon 304L and 316L, are specifically designed to have improved resistance to intergranular corrosion. Therefore, it is advisable to select the appropriate grade of stainless steel wire based on the specific application and environmental conditions to ensure optimum resistance to intergranular corrosion.

- Q: Can stainless steel wire be used for wire crochet hooks?

- Yes, stainless steel wire can be used for wire crochet hooks. Stainless steel is a durable and corrosion-resistant material, making it suitable for crochet hooks that may come into contact with moisture or other elements. Additionally, stainless steel is a strong and flexible material, allowing for smooth and seamless crochet stitches. However, it's important to note that the gauge or thickness of the stainless steel wire should be appropriate for the desired crochet project.

- Q: What are the different wire mesh options available in stainless steel wire?

- There are several different wire mesh options available in stainless steel wire, each with its own unique features and applications. 1. Plain Weave: This is the most common and basic type of stainless steel wire mesh. It is made by weaving the wires under and over each other in a simple crisscross pattern, resulting in a strong and durable mesh. Plain weave wire mesh is widely used in filtration, sieving, and screening applications. 2. Twill Weave: Twill weave wire mesh is characterized by a diagonal pattern created by passing the weft wire over and under two warp wires. This type of mesh offers a tighter weave and increased strength compared to plain weave. Twill weave wire mesh is commonly used in industrial filtration, separation, and conveyor belt applications. 3. Dutch Weave: Dutch weave wire mesh features a combination of a plain weave and a twill weave. It is made by using thick wires for the warp and thin wires for the weft, resulting in a highly durable and fine mesh. Dutch weave wire mesh is ideal for applications that require precise filtration and separation, such as in the chemical, pharmaceutical, and food industries. 4. Welded Wire Mesh: As the name suggests, welded wire mesh is made by welding the intersections of the wires together. This type of mesh offers excellent strength and rigidity, making it suitable for applications that require a strong barrier or reinforcement, such as in construction, fencing, and animal enclosures. 5. Reverse Dutch Weave: Reverse Dutch weave wire mesh is similar to Dutch weave, but the warp wires are thicker than the weft wires. This type of mesh is frequently used for high-pressure filtration applications, as the thicker warp wires provide greater stability and resistance to pressure. 6. Crimped Wire Mesh: Crimped wire mesh is made by weaving wires with crimped patterns, creating a mesh with uniform openings. This type of mesh is known for its flexibility and resilience, making it suitable for applications that require vibration resistance, such as in mining, construction, and architecture. These are just a few of the many wire mesh options available in stainless steel wire. The choice of mesh depends on the specific requirements of the application, such as filtration precision, strength, flexibility, and durability.

- Q: What stainless steel screws are best?

- Stainless steel screw material is generally A2-70, and if the ocean and other special corrosive environment, you have to change to 316L;Building is mainly to ask what type of screw, then this still needs reference working conditions and installation conditions

- Q: What are the different types of stainless steel wire ropes used in bridges?

- There are primarily two types of stainless steel wire ropes commonly used in bridges: 1x19 construction and 7x19 construction. The 1x19 construction is composed of a single strand with 19 wires tightly packed together, providing high strength and minimal flexibility. On the other hand, the 7x19 construction consists of seven strands, each with 19 wires, offering increased flexibility and durability. Both types of stainless steel wire ropes are suitable for various bridge applications, depending on the specific requirements and load capacities.

- Q: The difference between brushed stainless steel and mirror stainless steel

- Brushed stainless steel refers to: stainless steel surface like filamentous texture, this is only a stainless steel processing technology.

- Q: Can stainless steel wire be used for bicycle spokes?

- Certainly, bicycle spokes can indeed be made using stainless steel wire. Stainless steel wire has gained popularity as a preferred material for bicycle spokes owing to its remarkable attributes of robustness, enduring quality, and resistance against corrosion. These stainless steel spokes possess the capability to endure immense tension, thereby serving as a reliable support system for the bicycle wheel. Moreover, stainless steel showcases a desirable characteristic of being relatively lightweight while striking an excellent balance between strength and flexibility, rendering it a perfect choice for bicycle spokes.

- Q: What is the difference between stainless steel wire and cold wire drawing

- Stainless steel wire is a big category, that is to say, a large range, some varieties, such as: cold drawn medium hard wire, hydrogen yarn, spring wire, and so on

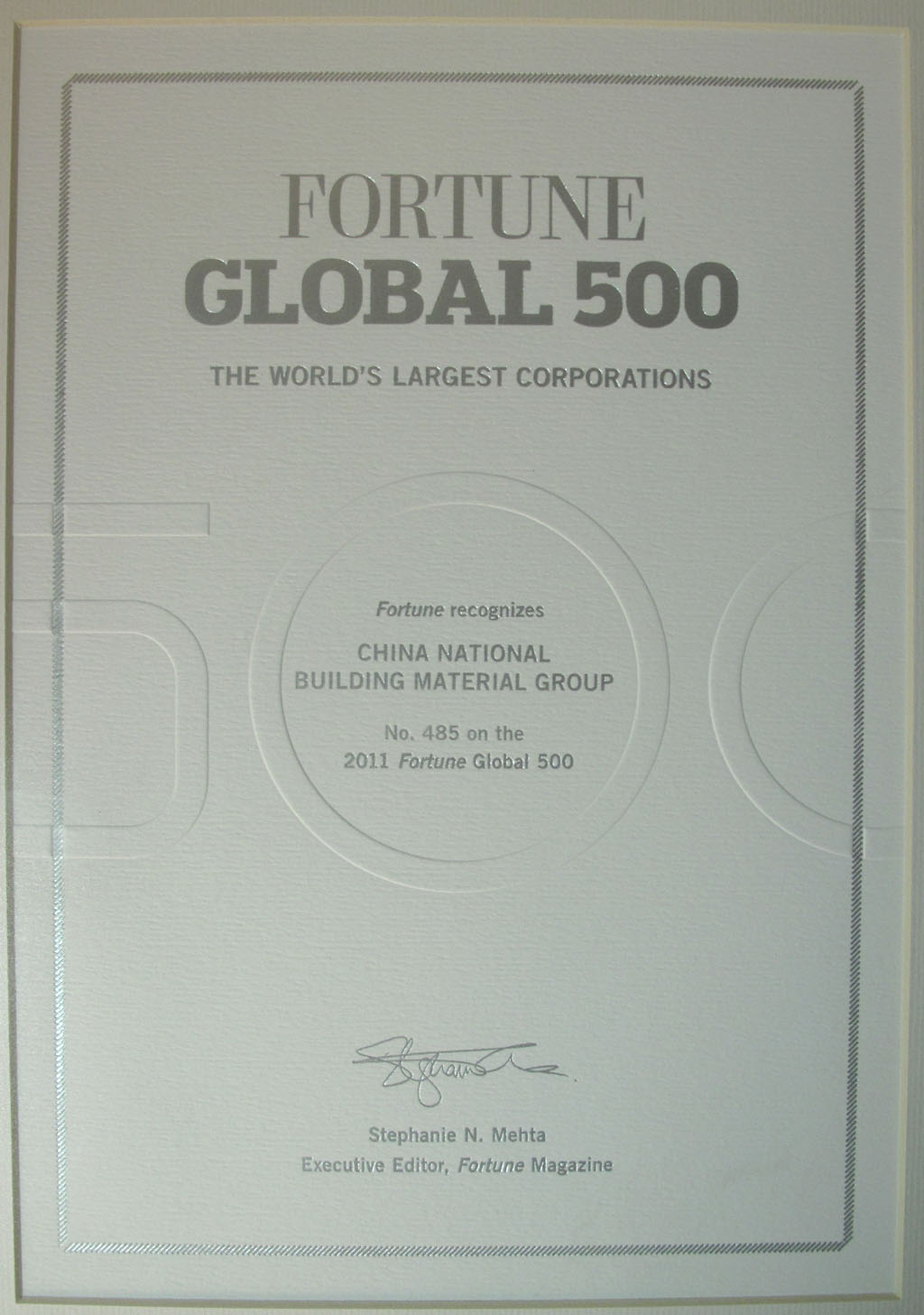

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

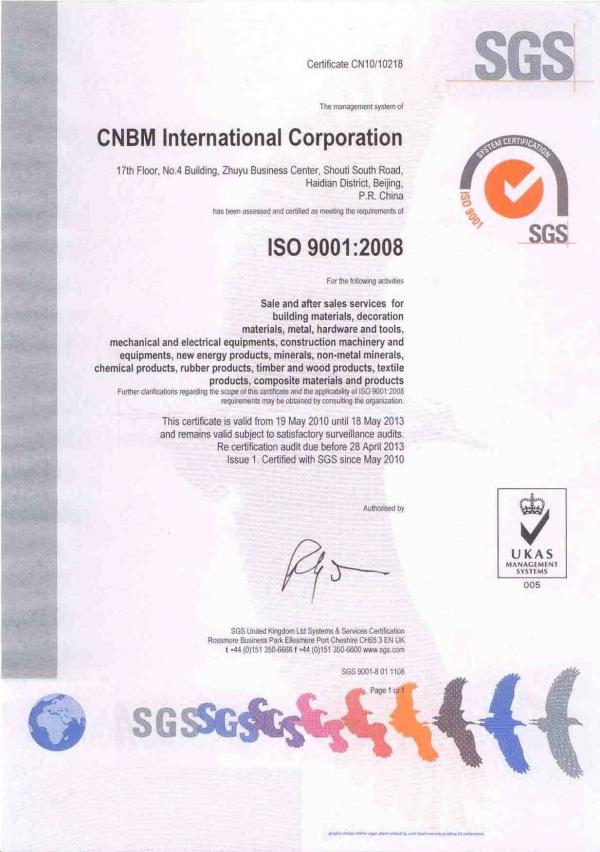

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords