Stainless Steel Coil ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Coil

• Decoration

• Daily Necessities

•,Medical Treatment

• Daily Necessities

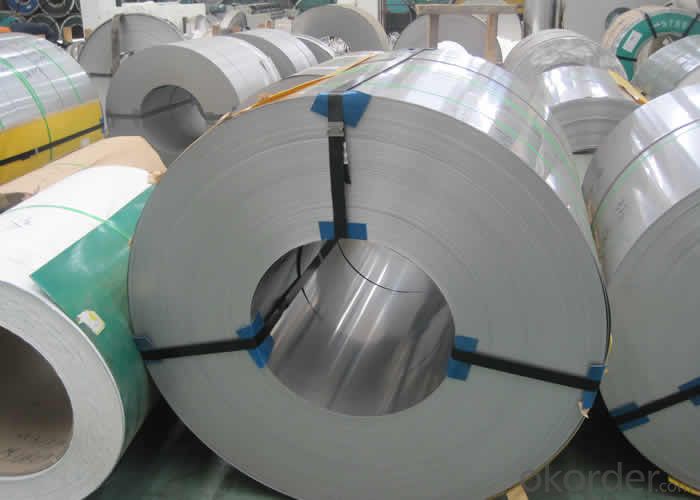

3. Stainless Steel Coil Images

4. Stainless Steel Coil Specification

Product Name | ASTM Standard 200,300,400 Series Stainless Steel Coil |

Standard | JIS AISI ASTM GB DIN |

Grade | 200/300/400 Series |

Thickness | 0.2mm-100mm |

Width | 100mm-2000mm |

Length | According to clients’ requirement |

Surface Finish | 2B ,BA ,8K ,NO4,NO2, NO1 ,Hair line ,EMBOSSED... |

Technique | Cold rolled ,Hot rolled |

Package | Seaworthy packing or as the consumers’ demand |

Application | Be used in manufacture of medical equipment, auto parts, heat-resistant kitchen utensils, electrical accessories , construction decoration ,etc |

Trade Term | FOB CIF |

Payment | T/T , L/C, D/P, D/A, Western Union, MoneyGram |

LoadingPort | Shanghai OR Qingdao |

Delivery Time | 3-7days,mainly in accordance with the quantity |

Report | Material report ,Mechanical performance report |

Certification | ISO9001 |

5.FAQ of Stainless Steel Coil

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: Are steel strips used in the production of oil and gas equipment?

- Yes, steel strips are commonly used in the production of oil and gas equipment. They are utilized for various applications such as manufacturing pipes, tanks, valves, and other components that require high strength, durability, and resistance to corrosion. Steel strips provide the necessary mechanical properties to withstand the demanding conditions of the oil and gas industry.

- Q: How are steel strips processed for plating?

- Steel strips are typically processed for plating through a series of steps. First, the strips are cleaned to remove any impurities or contaminants. This is followed by surface preparation, which may involve mechanical processes like grinding or sanding to ensure a smooth and even surface. Next, the strips are often treated with chemicals or acid solutions to further clean and activate the surface, promoting better plating adhesion. Finally, the steel strips are immersed in a plating bath where a layer of the desired metal, such as nickel or zinc, is deposited onto the surface through an electrochemical process.

- Q: How are steel strips used in the production of metal shelving?

- Steel strips are used in the production of metal shelving to provide structural support and stability. These strips are typically shaped and formed into brackets or supports that reinforce the shelves, ensuring they can hold heavy loads without bending or collapsing. The strips may also be used to create the frame or framework of the shelving unit, providing a strong and durable structure.

- Q: Are steel strips suitable for making electrical transformers?

- Yes, steel strips are suitable for making electrical transformers. Steel strips are commonly used as the core material in transformers due to their magnetic properties and ability to efficiently conduct and distribute electrical energy.

- Q: How do steel strips contribute to the durability of infrastructure?

- Steel strips, also known as steel reinforcement or rebar, play a crucial role in enhancing the durability of infrastructure. These strips are incorporated into various construction elements, such as concrete, to provide additional strength and prevent potential structural failure. One of the key contributions of steel strips to infrastructure durability is their ability to resist tension forces. Concrete is excellent in compression but weak in tension, making it prone to cracking or failure when subjected to excessive loads or environmental conditions. By adding steel strips to concrete elements, the overall structure becomes more resistant to tension, as the strips absorb and distribute the forces, thereby preventing cracks and enhancing its overall durability. Additionally, steel strips also improve the structural stability of infrastructure by reinforcing against bending and shearing forces. In bridges, for example, these strips are often used in the construction of beams and columns, providing strength and preventing excessive deflection or collapse under heavy traffic loads. Similarly, in high-rise buildings, steel strips are used to reinforce columns, walls, and slabs, ensuring the structure can withstand the vertical and lateral loads it may encounter. Furthermore, steel strips contribute to the durability of infrastructure by improving its resistance to corrosion. Steel is naturally susceptible to rust when exposed to moisture and air, which can weaken the structure over time. However, modern steel reinforcement is typically protected with a layer of epoxy coating or embedded within a concrete layer, safeguarding it against corrosion and extending its lifespan. In summary, steel strips significantly enhance the durability of infrastructure by reinforcing against tension, bending, and shearing forces. They prevent cracking, increase structural stability, and improve resistance to corrosion. By incorporating steel strips into construction elements, infrastructure can withstand various external factors, ensuring longevity and safety for years to come.

- Q: How are steel strips processed for interlocking?

- Steel strips are processed for interlocking through a series of steps that involve precision cutting, shaping, and assembly. The process begins with the selection of high-quality steel strips that meet the required specifications. These strips are then cut into specific lengths and widths using advanced cutting techniques such as shearing or laser cutting. After the initial cutting, the strips may undergo further processing to create interlocking features. This can involve shaping the edges of the strips to create interlocking profiles or adding specialized notches or grooves that allow for secure connections. Various machining techniques such as milling or grinding may be employed to achieve the desired interlocking design. Once the interlocking features are formed, the steel strips are carefully inspected for accuracy and quality. Any imperfections or burrs are removed through deburring or polishing processes to ensure smooth and precise interlocking. The final step in processing steel strips for interlocking involves assembly. The interlocking profiles of the strips are carefully aligned and joined together using welding, riveting, or other appropriate methods. This assembly process ensures that the interlocking steel strips form a strong and secure connection that can withstand the intended application's requirements. Overall, the processing of steel strips for interlocking involves a combination of cutting, shaping, and assembly techniques to create precise interlocking profiles. This ensures that the resulting interlocking system provides a reliable and durable solution for various applications such as construction, manufacturing, or infrastructure projects.

- Q: Can steel strips be used in the medical industry?

- Indeed, the medical industry has found great use for steel strips. These versatile strips have a multitude of applications within the field. Surgical instruments, medical implants, and medical equipment are just a few examples of the many uses for steel strips. The exceptional qualities of steel strips, such as strength, durability, and resistance to corrosion, make them ideal for applications requiring precision and reliability. They can be easily molded and shaped into various medical devices, ensuring that they meet the specific needs of both patients and healthcare professionals. In addition, steel strips can be treated on their surface to enhance their biocompatibility, rendering them suitable for use in implantable medical devices. The surface treatment offers added benefits, such as reducing the risk of infections and promoting better integration with the patient's body. Furthermore, steel strips possess excellent mechanical properties, allowing for precise machining and fabrication. They can be easily sterilized and cleaned, making them perfect for use in sterile environments. It is worth noting that stainless steel is commonly employed in the medical industry due to its resistance to corrosion and ability to withstand harsh sterilization processes. However, other types of steel can be used depending on the specific requirements of the medical application. In conclusion, the medical industry has embraced the use of steel strips due to their many advantageous properties. Their strength, durability, corrosion resistance, and compatibility with surface treatments make them a dependable choice for manufacturing surgical instruments, medical implants, and other medical equipment.

- Q: Can steel strips be used for making musical instrument strings?

- Yes, steel strips can be used for making musical instrument strings. Steel strings are commonly used in instruments such as guitars, pianos, and string instruments like violins and cellos. Steel offers durability, strength, and a bright, clear tone that is preferred by many musicians. The steel strips are typically processed and shaped into thin wires that are then wound or stretched to create the desired pitch and sound quality. However, it is worth noting that the specific characteristics and requirements of each instrument may vary, and different materials such as nylon or gut may be used for strings in certain instruments.

- Q: Can steel strips be used in the production of beverage cans?

- Yes, steel strips can be used in the production of beverage cans. Steel is a commonly used material for manufacturing cans due to its strength, durability, and ability to be easily shaped into the desired form. It is also known for its resistance to corrosion, which helps to maintain the quality and freshness of the beverages inside the cans.

- Q: How are steel strips processed for corrosion resistance?

- Steel strips are processed for corrosion resistance through a variety of methods, including surface treatments and coatings. One common method is hot-dip galvanizing, where the steel strip is immersed in a bath of molten zinc. This creates a protective layer of zinc on the surface of the steel, preventing corrosion and extending its lifespan. Another method is electroplating, which involves passing an electric current through the steel strip while it is submerged in an electrolyte solution containing a metal coating, such as zinc or nickel. The metal coating is then deposited onto the surface of the steel, providing a barrier against corrosion. Additionally, steel strips can be coated with organic coatings, such as paints or polymer films, to enhance corrosion resistance. These coatings form a protective barrier between the steel and the surrounding environment, preventing moisture and other corrosive agents from reaching the surface. Furthermore, steel strips can undergo a process called passivation, where a thin layer of oxide is formed on the surface of the steel. This oxide layer acts as a protective barrier against corrosion, preventing the steel from coming into direct contact with corrosive elements in the environment. Overall, the processing of steel strips for corrosion resistance involves various techniques, such as galvanizing, electroplating, organic coatings, and passivation. These methods help to enhance the longevity and performance of steel strips in corrosive environments.

Send your message to us

Stainless Steel Coil ASTM Standard 200,300,400 Series

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords