Stainless Steel Sheet SS 201/304/316/304L/316L/309S/310S/430

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Sheet Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Sheet

• Hardness (HB): ≤ 187

• Tensile strength (Mpa): ≥ 520

• Yield strength (Mpa): ≥ 205

• Elongation %: ≥ 40

• Reduction in area %: ≥ 50

• Recommended heat Treatment: 1030 ' C -1180 ' C

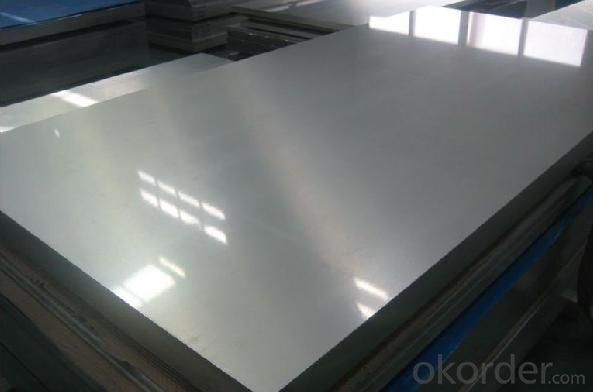

3. Stainless Steel Sheet Images

4. Stainless Steel Sheet Specification

| Grade: | 200series.300series. | Standard: | JIS,AISI,ASTM | Length: | as request |

| Thickness: | 0.3-3mm | Width: | 30-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | ss201/304/316/304L/316L/309S/310S/430 | Type: | Plate |

| Application: | hardware, foodstuff, manufacture, medic | Certification: | SGS | Item: | ss202/304/316/309s/310/410/420 stainless steel sheet |

| Packaging: | Export standard package or as your requirement | Delivery: | In 15 days | Stock: | Available |

5.FAQ of Stainless Steel Sheet

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: Can steel strips be used in the manufacturing of consumer goods?

- Consumer goods can indeed utilize steel strips in their manufacturing process. With their versatility and wide range of applications, steel strips find their place in various industries, including consumer goods manufacturing. From appliances to automotive parts, electronics to furniture, and numerous other consumer products, steel strips play a significant role. The advantages they offer, including high strength, durability, and corrosion resistance, make them an ideal choice for consumer goods that prioritize these properties. Furthermore, steel strips can be effortlessly shaped, formed, and adjusted to meet specific product specifications.

- Q: What are the storage guidelines for steel strips?

- To ensure the longevity and prevent damage of steel strips, it is important to adhere to storage guidelines. Firstly, it is crucial to store them in a dry and well-ventilated area to avoid the accumulation of moisture which can lead to corrosion. Direct exposure to sunlight should be avoided as it can cause discoloration and degradation of the steel's surface. Furthermore, steel strips should be stored horizontally, either stacked or on racks, to prevent bending or warping. It is advisable to place wooden or rubber spacers between layers to provide support and prevent contact between the strips which may cause scratching or other surface damage. When stacking the strips, it is necessary to evenly distribute the weight to avoid excessive pressure on the lower strips. Additionally, they should be kept away from chemicals or substances that may stain or react with the steel. Regular inspections should be carried out to identify any rust or damage. If any issues are found, appropriate measures such as cleaning, applying rust inhibitors, or seeking professional assistance should be taken. By following these storage guidelines, steel strips can be preserved in optimal condition, ensuring their quality and performance in various applications.

- Q: What are the different types of corrosion protection for steel strips?

- There are several different types of corrosion protection methods for steel strips, including galvanization, painting, powder coating, and the use of corrosion inhibitors. Galvanization involves coating the steel strips with a layer of zinc, which provides a sacrificial barrier, protecting the underlying steel from corrosion. Painting and powder coating involve applying a protective layer of paint or powder on the steel, which acts as a barrier against moisture and corrosive elements. Corrosion inhibitors are chemical compounds that can be applied to the steel strip's surface to prevent corrosion by forming a protective layer.

- Q: How are steel strips used in the production of automotive exhaust systems?

- Automotive exhaust systems rely heavily on steel strips as a vital element. These strips are typically crafted from top-notch stainless steel due to its exceptional endurance, heat resistance, and ability to resist corrosion. One of the primary functions of steel strips in exhaust systems is the production of exhaust pipes. These pipes must be capable of enduring extreme temperatures and corrosive gases released by the engine. Steel strips are shaped into cylindrical forms and fused together to create the main body of the exhaust pipe. The strength and heat resistance of the steel strips guarantee that the pipe can withstand the harsh conditions within the exhaust system. Furthermore, steel strips are also utilized in the manufacturing of various components found in the exhaust system, such as mufflers and resonators. Mufflers are responsible for reducing engine noise by employing baffles and chambers to disperse sound waves. Steel strips are molded and formed to construct the outer shell of the muffler, providing it with structural integrity and durability. On the other hand, resonators are employed to fine-tune the exhaust sound and minimize unwanted vibrations. Steel strips are used to fashion the internal chambers and baffles within the resonator to achieve the desired acoustic effects. Moreover, steel strips play a crucial role in the production of the exhaust manifold, which gathers exhaust gases from each cylinder and directs them into the exhaust system. The steel strips are skillfully shaped and welded together to create a robust and leak-free manifold that can withstand high temperatures and pressures. In conclusion, steel strips are an essential aspect of automotive exhaust system production. Their strength, heat resistance, and corrosion resistance properties make them ideal for constructing various components within the system, ensuring durability, performance, and longevity.

- Q: Can steel strips be used in the production of food packaging materials?

- Yes, steel strips can be used in the production of food packaging materials. Steel strips are often used to make cans and other food packaging containers because they provide strength, durability, and protection for the food inside. Additionally, steel is a non-toxic material that does not interact with or contaminate the food, making it a safe choice for food packaging.

- Q: How are steel strips used in the manufacturing of electronic components?

- Steel strips are used in the manufacturing of electronic components as a base material for various purposes such as shielding, connectors, and brackets. They provide structural support, electromagnetic interference (EMI) protection, and mechanical stability to ensure the proper functioning and durability of electronic devices.

- Q: Can steel strips be used for making precision turned parts?

- Certainly! Precision turned parts can indeed be made using steel strips. These strips possess great versatility and can be machined into a wide range of shapes and sizes, all while maintaining strict tolerances. Consequently, they are highly suitable for precision turning procedures. The exceptional hardness and strength of steel strips render them perfect for applications demanding endurance and resistance to wear, such as precision turned parts utilized in the automotive, aerospace, and manufacturing sectors. Moreover, steel strips can be readily obtained in diverse grades and compositions, thereby facilitating customization to meet specific needs.

- Q: Steel industry, strip 195, where can strip be used?

- Q195 carbon content is low, the strength is not high, plasticity, toughness, processing and welding performance is better.

- Q: Are steel strips suitable for construction purposes?

- Yes, steel strips are suitable for construction purposes. Steel strips are strong, durable, and resistant to corrosion, making them an excellent choice for various construction applications such as framing, support structures, and reinforcement. They provide stability and structural integrity to buildings and can withstand heavy loads, making them ideal for construction purposes.

- Q: What are the different lengths available for steel strips?

- Steel strips come in various lengths to accommodate different applications and requirements. The lengths of these strips can vary from a few inches to several feet, depending on the intended purpose and the industry. Standard sizes for steel strips include 12 inches, 24 inches, 36 inches, and so forth. However, it is also possible to obtain custom lengths by cutting longer strips to the desired size. Furthermore, steel strips can be supplied in rolls or coils, which can have different lengths depending on the thickness and width of the strip. Ultimately, the length of steel strips is determined by factors such as the specific industry, the intended purpose, and the customer's specifications.

Send your message to us

Stainless Steel Sheet SS 201/304/316/304L/316L/309S/310S/430

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords