403 Stainless Steel

403 Stainless Steel Related Searches

409 Stainless Steel Stainless Steel 303 400 Stainless Steel 410 Stainless Steel 400 Series Stainless Steel 440 Stainless Steel 430 Stainless Steel 420 Stainless Steel Stainless Steel 430 300 Stainless Steel Stainless Steel 440 440 C Stainless Steel Stainless Steel 420 A4 Stainless Steel 440c Stainless Steel 330 Stainless Steel Stainless Steel 316 305 Stainless Steel 440a Stainless Steel 309 Stainless Steel 420c Stainless Steel 310 Stainless Steel Grade 304 Stainless Steel 301 Stainless Steel 455 Stainless Steel 300 Series Stainless Steel 420hc Stainless Steel 4 Stainless Steel 304 Grade Stainless Steel 304l Stainless Steel403 Stainless Steel Supplier & Manufacturer from China

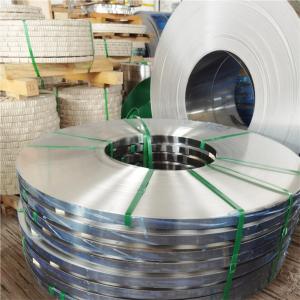

403 Stainless Steel is a type of martensitic stainless steel that is known for its excellent corrosion resistance and mechanical properties. This product is widely recognized for its ability to maintain strength and durability in various environments, making it a popular choice for numerous applications. The product's versatility allows it to be utilized in a wide range of industries, including automotive, aerospace, and construction, where it is used for components that require high strength and resistance to wear and tear. Okorder.com is a leading wholesale supplier of 403 Stainless Steel, boasting a substantial inventory that caters to the diverse needs of customers across different sectors. By offering a comprehensive selection of this product, Okorder.com ensures that clients have access to high-quality 403 Stainless Steel at competitive prices, making it an ideal choice for businesses looking to source this material for their projects.Hot Products