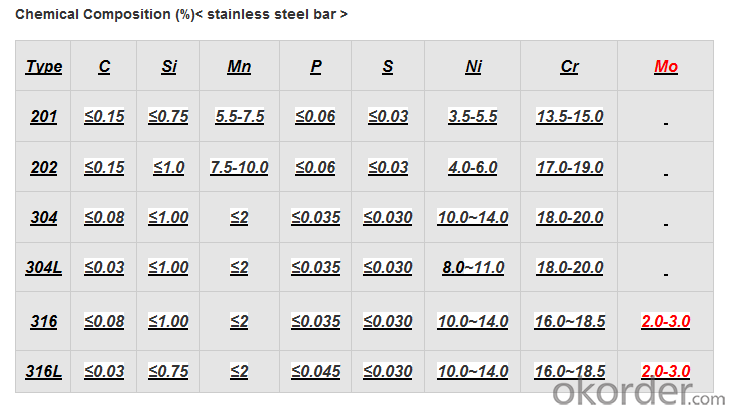

201 304 304L 316 316L Stainless Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201 304 304L 316 316L Stainless Steel Bar

Product information:

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: What are the different heat treatment processes used for special steel?

- Some of the different heat treatment processes used for special steel include annealing, tempering, quenching, and hardening.

- Q: How does special steel perform in terms of corrosion resistance in acidic environments?

- Special steel, also known as stainless steel, is highly regarded for its exceptional corrosion resistance in various environments, including acidic conditions. It contains a minimum of 10.5% chromium, which forms a protective layer on the surface of the steel known as a passive film. This passive film acts as a barrier, preventing the steel from coming into direct contact with the corrosive elements present in acidic environments. The chromium content in special steel enables it to react with oxygen in the atmosphere, creating a thin and transparent oxide layer. This oxide layer is highly stable and self-healing, making stainless steel highly resistant to corrosion caused by acids. The presence of other alloying elements such as nickel and molybdenum further enhances its resistance to acidic corrosion. In acidic environments, special steel exhibits excellent resistance to both general corrosion and localized corrosion, such as pitting and crevice corrosion. It can withstand a wide range of acid concentrations and temperatures, making it suitable for applications in industries such as chemical processing, pharmaceuticals, and marine environments where exposure to acidic solutions is common. It is important to note that the performance of special steel in acidic environments may vary depending on the specific grade and composition of the steel. Different grades of stainless steel have varying levels of alloying elements, which can influence their corrosion resistance properties. Therefore, it is essential to select the appropriate grade of special steel that matches the specific acidic environment to ensure optimal performance and longevity.

- Q: What are the different forming techniques used for special steel?

- Some of the different forming techniques used for special steel include forging, casting, rolling, and extrusion.

- Q: What are the properties of shock-resistant alloy steel?

- Shock-resistant alloy steel is a type of steel that possesses specific properties that make it highly resistant to shock and impact. These properties include high tensile strength, toughness, and hardness. It is also known for its ability to withstand sudden changes in temperature, making it suitable for applications in extreme environments. Additionally, shock-resistant alloy steel has excellent fatigue resistance, corrosion resistance, and wear resistance, making it ideal for use in industries such as aerospace, automotive, and defense.

- Q: Can special steel be used in the aerospace defense industry?

- Yes, special steel can be used in the aerospace defense industry. It is commonly used for manufacturing various components and structures in aircraft and defense systems due to its high strength, durability, and resistance to extreme temperatures and corrosion.

- Q: What are the requirements for special steel used in agricultural machinery?

- The requirements for special steel used in agricultural machinery include high strength and durability to withstand heavy loads and harsh working conditions, excellent impact resistance to handle rough terrains, good corrosion resistance to protect against rust and moisture, and high wear resistance to prolong the lifespan of components exposed to abrasive materials. Additionally, the steel should have good weldability and machinability to facilitate the manufacturing process of agricultural machinery.

- Q: How does bearing steel contribute to the manufacturing of bearings?

- Bearing steel is a crucial material in the manufacturing of bearings as it provides the necessary strength, durability, and wear resistance required for the efficient operation of bearings. The high carbon content in bearing steel enhances its hardness and strength, ensuring that the bearings can withstand heavy loads, high speeds, and extreme operating conditions. Additionally, the unique composition and heat treatment of bearing steel enable it to maintain dimensional stability and minimize friction, leading to improved performance and longer life of the bearings.

- Q: How does special steel contribute to the automotive parts industry?

- Special steel plays a crucial role in the automotive parts industry by providing enhanced strength, durability, and performance to various components used in vehicles. With its unique properties, special steel helps in improving the overall safety, reliability, and efficiency of automobiles. One of the key contributions of special steel to the automotive parts industry is its ability to withstand high temperatures, pressures, and extreme conditions. This makes it ideal for manufacturing engine parts such as crankshafts, camshafts, and connecting rods, which are subject to intense mechanical stress and heat. Special steel ensures that these critical components can endure the demanding conditions of combustion engines, resulting in improved engine performance and longevity. Another significant contribution of special steel is its corrosion resistance. Automotive parts are exposed to various corrosive elements like moisture, chemicals, and road salt. Special steel enables the production of corrosion-resistant parts such as exhaust systems, suspension components, and brake rotors, which are vital for maintaining the structural integrity and safety of vehicles over time. Moreover, special steel offers exceptional formability and weldability, allowing manufacturers to produce complex automotive parts with precision and ease. This versatility makes it possible to create lightweight yet strong components like chassis, body panels, and suspension arms, which contribute to fuel efficiency, handling, and overall vehicle performance. Furthermore, special steel's high tensile strength and toughness contribute to the safety of vehicles by ensuring the structural integrity of safety-critical parts such as steering columns, seat frames, and roll bars. These components play a vital role in protecting occupants during accidents and collisions, making special steel an essential material for enhancing overall vehicle safety. In conclusion, special steel's unique properties and characteristics significantly contribute to the automotive parts industry. Its strength, durability, corrosion resistance, formability, and weldability make it an ideal material for manufacturing critical components in automobiles. By incorporating special steel into various parts, vehicles can achieve improved performance, safety, and reliability while meeting the demands of modern automotive standards.

- Q: What are the challenges in surface treating special steel?

- Some of the challenges in surface treating special steel include achieving uniform and consistent coatings, ensuring adhesion of the coating to the steel substrate, overcoming the high hardness of the steel, preventing distortion or warping during the treatment process, and managing the potential for thermal degradation or oxidation. Additionally, the presence of unique alloying elements in special steel may require specialized treatment techniques to achieve the desired surface properties.

- Q: How is high-strength steel used in the automotive industry?

- High-strength steel is widely used in the automotive industry for its ability to enhance the safety and performance of vehicles. It is used in various components such as the frame, chassis, and body structure to improve structural integrity, reduce weight, and provide better crash protection. Additionally, high-strength steel allows automakers to design vehicles with improved fuel efficiency and increased load-carrying capacity, making it a crucial material in modern automotive manufacturing.

Send your message to us

201 304 304L 316 316L Stainless Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords