Stainless Steel Round Bar 304_304L with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Round Bar 304_304L with High Quality

Details of Stainless Steel Round Bar 304_304L with High Quality

Name | Stainless Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

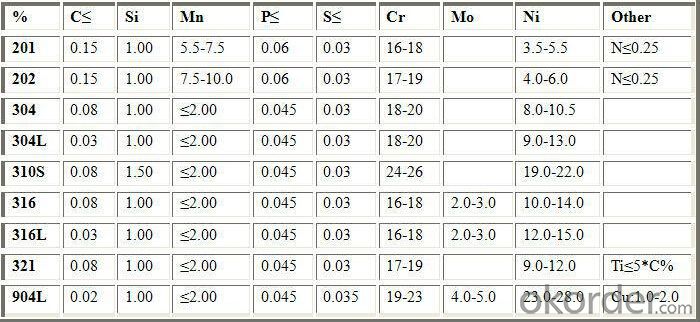

Specification of Stainless Steel Round Bar 304_304L with High Quality

CNBM Introduction of Stainless Steel Round Bar 304_304L with High Quality

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Stainless Steel Round Bar 304_304L with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different mechanical properties of steel round bars?

- The different mechanical properties of steel round bars include tensile strength, yield strength, elongation, hardness, and impact resistance. Tensile strength refers to the maximum amount of stress a material can withstand before breaking. Yield strength is the stress at which a material begins to deform permanently. Elongation measures the amount of deformation a material can undergo before breaking. Hardness determines the material's resistance to indentation or scratching. Impact resistance is the ability of a material to absorb energy during sudden impacts without breaking.

- Q: Can steel round bars be used in the production of bearings?

- It is not possible to use steel round bars in the production of bearings. Bearings necessitate particular materials capable of enduring heavy loads and providing minimal friction. Steel round bars lack the essential attributes required to meet these criteria. Instead, bearings are typically manufactured from specialized materials such as chrome steel, stainless steel, or ceramics. These materials exhibit exceptional durability and performance, even in the challenging conditions under which bearings function.

- Q: Can steel round bars be used in the automotive manufacturing?

- Yes, steel round bars can be used in automotive manufacturing. Steel round bars offer high strength and durability, making them suitable for various automotive components such as crankshafts, camshafts, axles, and suspension parts. They also provide excellent machinability and can be easily fabricated into the required shapes and sizes, making them a preferred choice in the automotive industry.

- Q: What are the different types of steel round bar surface finishes for corrosion resistance?

- Corrosion resistance in steel round bars can be achieved through various surface finishes. These finishes effectively shield the bar from corrosive elements, reducing the risk of rust or degradation over time. Hot-dip galvanizing is a popular choice for corrosion resistance. It entails immersing the steel round bar in molten zinc, which creates a protective zinc coating. This sacrificial anode corrodes before the steel, providing long-lasting protection against rust and corrosion. Stainless steel is another common surface finish for corrosion resistance. With a minimum chromium content of 10.5%, it forms a passive oxide layer when exposed to oxygen. This layer acts as a barrier, preventing further oxidation and corrosion, making stainless steel round bars highly resistant to rust. Electroplating is a method used to provide corrosion resistance. By immersing the bar in an electrolyte solution and passing an electric current through it, a layer of metal like zinc or nickel is deposited onto the surface, offering a protective coating. For steel round bars that require both corrosion resistance and aesthetic appeal, powder coating is a popular choice. This process involves applying a dry powder coating to the surface and curing it under heat. The resulting hard, durable finish not only offers excellent corrosion resistance but also provides a variety of color options. There are also specialized coatings available for specific applications, such as epoxy or polymer coatings. These coatings offer superior resistance to particular corrosive environments, like exposure to chemicals or high humidity. In conclusion, there are several types of surface finishes for corrosion resistance in steel round bars. These include hot-dip galvanizing, stainless steel, electroplating, powder coating, and specialized coatings. The choice of finish depends on factors such as the specific application, environmental conditions, and desired aesthetics.

- Q: What are the environmental impacts of steel round bar production?

- The production of steel round bars has several environmental impacts. Firstly, the extraction of raw materials such as iron ore and coal required for steel production leads to habitat destruction, deforestation, and disruption of ecosystems. Mining activities also generate large amounts of waste, including tailings and waste rock, which can contaminate soil, water bodies, and air. The process of converting iron ore into steel involves high energy consumption, primarily from fossil fuels. The burning of these fuels releases greenhouse gases, such as carbon dioxide and nitrogen oxides, contributing to climate change and air pollution. Additionally, steel production releases particulate matter, sulfur dioxide, and other pollutants that can have detrimental effects on human health and ecosystems. Steel manufacturing also requires significant amounts of water for cooling, cleaning, and processing. This can lead to water scarcity and pollution if proper water management practices are not in place. Discharge of untreated or inadequately treated wastewater from steel production can contaminate nearby water sources, affecting aquatic life and potentially harming human populations who rely on these water bodies. Furthermore, the transportation of raw materials and finished steel products over long distances contributes to carbon emissions and air pollution. The energy-intensive nature of steel production and transportation further exacerbates the overall environmental impacts of the industry. To mitigate these environmental impacts, the steel industry has been implementing various measures. These include the use of more efficient technologies, such as recycling and minimization of waste, improving energy efficiency, and adopting cleaner production processes. Additionally, the industry has been focusing on reducing its carbon footprint by increasing the use of renewable energy sources and implementing carbon capture and storage technologies. Overall, while steel round bar production contributes to environmental degradation, there are ongoing efforts within the industry to minimize its negative impacts and transition towards more sustainable practices.

- Q: Why do I use the M25 round bar for the embedded bolt M24?

- Because there is no 24 of the bar specifications, only 25

- Q: Can steel round bars be used in the manufacturing of automotive parts?

- Yes, steel round bars can indeed be used in the manufacturing of automotive parts. Steel round bars offer several advantages that make them suitable for this purpose. Firstly, steel is a strong and durable material, making it ideal for automotive components that require high strength and structural integrity. Additionally, steel round bars can be easily machined and formed into various shapes and sizes, allowing for the production of customized automotive parts. Moreover, steel has excellent heat resistance and can withstand high temperatures, making it suitable for engine components and other parts exposed to extreme heat. Lastly, steel is a cost-effective material, making it a popular choice in the automotive industry. Overall, steel round bars are a reliable and versatile option for the manufacturing of automotive parts.

- Q: Are steel round bars suitable for the production of gears?

- Yes, steel round bars are suitable for the production of gears. Steel is a common material used in gear manufacturing due to its high strength, durability, and resistance to wear and tear. The round bar shape allows for easy machining and shaping of the gear teeth. Steel round bars also provide excellent hardness and toughness, ensuring that the gears can withstand heavy loads and operate smoothly. Additionally, steel can be heat treated to further enhance its mechanical properties, making it an ideal choice for gear production.

- Q: What are the advantages of using nickel-silicon alloy steel round bars?

- There are several advantages of using nickel-silicon alloy steel round bars. Firstly, nickel-silicon alloy steel has excellent high-temperature strength and resistance to oxidation and corrosion. This makes it a suitable material for applications that involve exposure to extreme temperatures or harsh environments, such as in the aerospace and automotive industries. Secondly, nickel-silicon alloy steel round bars offer superior mechanical properties, including high tensile and yield strength. This makes them ideal for use in structural components that require high strength and durability, such as in construction and engineering projects. Additionally, nickel-silicon alloy steel round bars have excellent resistance to fatigue and wear, making them suitable for applications that involve repetitive stress or abrasive conditions. This ensures a longer lifespan and reduced maintenance requirements for the components made from this material. Furthermore, nickel-silicon alloy steel is known for its excellent magnetic properties, making it suitable for use in electromagnetic applications such as transformers, motors, and generators. Lastly, nickel-silicon alloy steel round bars can be easily machined and fabricated, allowing for greater design flexibility and ease of manufacturing. This makes it an economical choice for various industries, as it reduces production costs and lead times. In summary, the advantages of using nickel-silicon alloy steel round bars include high temperature resistance, excellent mechanical properties, resistance to fatigue and wear, superior magnetic properties, and ease of machining and fabrication.

- Q: What is the maximum molybdenum content allowed for steel round bars?

- The maximum molybdenum content allowed for steel round bars varies depending on the grade and specific requirements of the steel. Generally, the maximum molybdenum content for standard carbon and alloy steels is around 0.25-0.30%. However, for high-performance steels such as tool steels or stainless steels, the maximum molybdenum content can be higher, ranging from 1-10%, depending on the specific grade and application. It is crucial to consult the relevant industry standards, specifications, or material data sheets to determine the precise maximum molybdenum content allowed for a specific steel round bar.

Send your message to us

Stainless Steel Round Bar 304_304L with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords