Stainless Steel Angles SS200,300,400 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

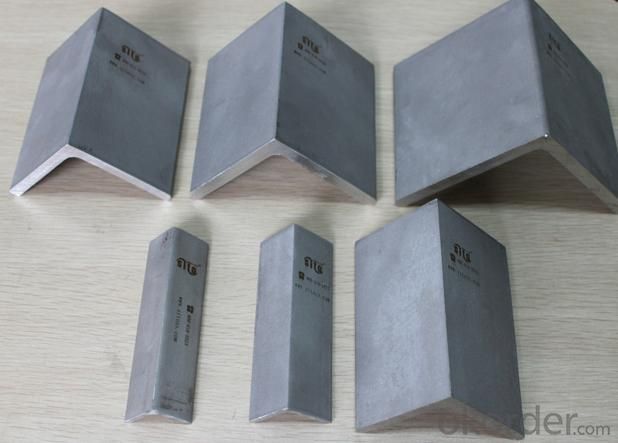

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

| |||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 |

| ||

Mo |

|

|

| 2.0-3.0 |

| ||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

- Q: How are stainless steel angles measured?

- Stainless steel angles are typically measured using two main dimensions: the length of each leg and the thickness of the material. The length of each leg refers to the distance from the point of intersection to the end of the leg, while the thickness is the measurement of the material from one edge to the other. These dimensions are usually expressed in inches or millimeters. Additionally, the angle itself is often referred to by its nominal size, which is based on the length of the legs. For example, a stainless steel angle with equal leg lengths of 2 inches would be referred to as a 2-inch angle. Overall, measuring stainless steel angles involves taking into account the length of the legs, the thickness of the material, and the nominal size of the angle.

- Q: Can stainless steel angles be used in industrial shelving systems?

- Yes, stainless steel angles can be used in industrial shelving systems. Stainless steel is highly durable and resistant to corrosion, making it suitable for industrial environments. It provides strength and stability to support heavy loads, making it an ideal choice for shelving systems in industries.

- Q: What is the maximum thickness for stainless steel angles?

- The maximum thickness for stainless steel angles can vary depending on the specific grade and manufacturing process, but it typically ranges from 1/8 inch to 1 inch or more.

- Q: How does stainless steel angle perform in high-velocity wind environments?

- Stainless steel angle performs exceptionally well in high-velocity wind environments. Stainless steel is known for its high strength and durability, making it an ideal material for withstanding extreme weather conditions, including high winds. The angled shape of stainless steel angle also helps in diverting wind forces and reducing the risk of structural damage or failure. Additionally, stainless steel is highly resistant to corrosion, meaning it can withstand the harsh elements associated with high-velocity winds, such as saltwater and intense rainfall. Overall, stainless steel angle is a reliable and robust choice for structures that need to withstand high-velocity wind environments.

- Q: Is stainless steel angle recyclable?

- Yes, stainless steel angle is recyclable. Stainless steel is a highly recyclable material and can be recycled repeatedly without losing its properties. The recycling process for stainless steel involves melting down the metal and then reshaping it into new products. This makes stainless steel angle a sustainable and eco-friendly choice for various applications. Additionally, recycling stainless steel helps to conserve natural resources and reduces the need for mining and extraction of raw materials.

- Q: Can stainless steel angles be used in food and beverage industries?

- Yes, stainless steel angles can be commonly used in the food and beverage industries. Stainless steel is highly resistant to corrosion, easy to clean, and does not react with food or beverages, making it a safe and hygienic material choice. It is also strong, durable, and able to withstand extreme temperatures, making it suitable for various food processing and storage applications.

- Q: Are stainless steel angles suitable for decorative applications?

- Yes, stainless steel angles are suitable for decorative applications. Their sleek appearance, durability, and corrosion resistance make them a popular choice for various decorative elements such as trim, edging, accents, and frames. They can be easily shaped, polished, and finished to match different design concepts, making them a versatile option for adding a touch of elegance and modernity to any decorative project.

- Q: Are stainless steel angles resistant to saltwater?

- Indeed, saltwater poses no threat to stainless steel angles. Renowned for its exceptional resistance to corrosion, stainless steel exhibits remarkable durability against the detrimental impact of saltwater. This resilience can be attributed to the abundant chromium content within stainless steel, which engenders the formation of a safeguarding oxide layer on the surface, effectively prohibiting the occurrence of corrosion and rust. Consequently, stainless steel angles find extensive utilization in marine settings, as well as diverse saltwater applications including shipbuilding, offshore platforms, marine structures, and coastal construction.

- Q: Can stainless steel angle be used in automotive or transportation applications?

- Yes, stainless steel angle can be used in automotive or transportation applications. Stainless steel is known for its high strength, durability, and corrosion resistance, making it an ideal material for various components in vehicles and transportation systems. Stainless steel angle can be used for structural support, framing, reinforcement, and bracketry in automotive applications such as chassis, body panels, exhaust systems, and suspension components. It can also be used in the construction of transportation infrastructure, including bridges and rail systems. Additionally, stainless steel angle is often used in the fabrication of trailers, truck beds, and other transportation equipment due to its ability to withstand heavy loads and harsh environmental conditions. Overall, the unique properties of stainless steel make it a reliable and versatile choice for automotive and transportation applications.

- Q: How do you calculate the torsional resistance of a stainless steel angle?

- To calculate the torsional resistance of a stainless steel angle, you need to consider its geometry, material properties, and loading conditions. The torsional resistance is a measure of how much torque the angle can withstand without deformation or failure. Here is a step-by-step process to calculate the torsional resistance: 1. Determine the cross-sectional properties: Measure or obtain the dimensions of the stainless steel angle, including the thickness, width, and length of the legs. Using these dimensions, calculate the area and moment of inertia of the cross-section. 2. Determine the material properties: Stainless steel has various grades, each with different mechanical properties. Identify the specific grade of stainless steel you are working with and obtain the necessary material properties, such as the shear modulus (G), yield strength (σy), and ultimate tensile strength (σu). 3. Calculate the polar moment of inertia: The polar moment of inertia (J) represents the resistance of the cross-section to torsion. It can be calculated using the moment of inertia (I) and the area (A) of the cross-section, using the equation J = 2I/A. 4. Determine the maximum allowable shear stress: The maximum allowable shear stress (τmax) is typically a fraction of the yield strength of the stainless steel. It ensures that the material remains within its elastic limits and avoids permanent deformation. Common values for τmax range from 0.4 to 0.6 times the yield strength. 5. Calculate the torsional resistance: The torsional resistance (T) can be calculated using the equation T = τmax * J, where τmax is the maximum allowable shear stress and J is the polar moment of inertia. It is important to note that this calculation assumes a linear elastic behavior of the stainless steel angle. For more accurate results, additional factors such as stress concentrations, strain hardening, and boundary conditions should be considered. Consulting relevant design codes and standards specific to stainless steel angles is recommended to ensure safety and accuracy in your calculations.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | above US$16 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 30000 square meter |

| No. of Production Lines | above 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Angles SS200,300,400 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords