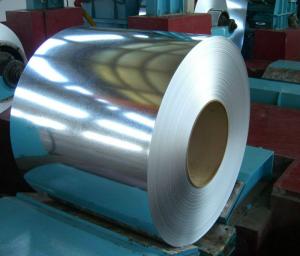

galvanized steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t. m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Grade: SGH340, DX51D and SGCC (customized)

Surface treatment: passivation, oiling, chromed, unoiled

Spangle types: minimal, zero and large

Thickness: 0.37 to 3.5mm

Width: greater than 1,000mm

Inner diameter: 508 to 610mm

Zinc coating: greater than 80g/m2

Applications:

Construction, home appliance, hardware and machinery

Standards:

JIS g3302 1998, ASTM a653 2003, EN10142 1990

EN10327 2004, AS1397 2001, GB2518-2004

Packing: export packing/sea worthy for international delivery

- Q: I noticed a friend's appliances are not magnetic, and mine are. Both are stainless steel. Are there two types of stainless steel or something? Thanks

- There are many types of stainless steel. Some are magnetic and some are non-magnetic. The magnetic properties of stainless steel are very dependent on the elements added into the alloy, and specifically the addition of nickel can change the structure from magnetic to non-magnetic. Poor heat treatment or high heat input welding of normal or high carbon austenitic stainless steels will cause sensitization, ie formation of chromium carbides. The formation of carbides not only reduces the corrosion resistance of the stainless steel but also tends to form martensite around the carbide. This martensite is magnetic and the more severe the sensitisation, the stronger are the magnetic properties. When nickel is added, for instance, the austenite structure of iron is stabilized. This crystal structure makes such steels non-magnetic and less brittle at low temperatures. Martensitic stainless steels are magnetic. *Wrought, austenitic stainless steels, such as 304 and 316, are generally regarded as non-magnetic in the annealed condition, ie they are not attracted significantly by a magnet. However, if they are cold worked they will be attracted to a permanent magnet. The change occurs because the cold work deformation induces a transformation of the microstructure from austenite to martensite. The effect is less marked in alloys with high concentrations of austenite stabilisers such as nickel, nitrogen and carbon. Once the martensite is formed, it may also become magnetised. *In contrast to the austenitic alloys, ferritic stainless steels such as 409 or 3Cr12/5Cr12 and martensitic stainless steels such as 420, are strongly attracted to a magnet even in the annealed state. The duplex and super-duplex stainless steels will also be strongly attracted because they contain about 50% ferrite in their microstructure. *

- Q: What is galvanized steel coil?

- Galvanized steel coil is a type of steel that has been coated with a layer of zinc to protect it from corrosion. The process of galvanization involves immersing the steel coil in a bath of molten zinc, which forms a protective layer on the surface of the steel. This layer not only prevents corrosion but also provides a barrier against scratches and other damage. Galvanized steel coil is commonly used in various industries, including construction, automotive, and manufacturing, due to its durability and resistance to rust. It is often used for making roofing materials, pipes, and automotive parts, among other applications. Overall, galvanized steel coil is a versatile and cost-effective solution for ensuring the longevity and integrity of steel products.

- Q: What are the dimensions of steel coils used in the structural component industry?

- The dimensions of steel coils utilized in the structural component sector are subject to variation, contingent upon the particular application and specifications. Nevertheless, standard dimensions for steel coils in this industry encompass a width that ranges between 600mm and 2000mm, as well as a thickness that spans from 0.25mm to 10mm. The weight of these coils may also differ, typically ranging from a few kilograms to numerous tonnes. Furthermore, the length of the steel coils can be customized to fulfill the specific demands of the structural component industry, with commonplace lengths including 2000mm, 2500mm, and 3000mm. It is vital to acknowledge that these dimensions are not exhaustive and are susceptible to variation based on the specific product and manufacturer.

- Q: i have recently gotten into DIY and am planning on making my own knife. My question is what kind of steel would be good to use for heat treating if i plan on using water and not oil in the process.

- Go to junkyard get old leaf spring, cut out knife, start sharpening. Why waste time heat treating steel when the spring steel as already be done.

- Q: What are the applications of stainless steel coils?

- Stainless steel coils have a wide range of applications across various industries due to their unique properties and characteristics. Some of the key applications of stainless steel coils include: 1. Manufacturing industry: Stainless steel coils are extensively used in the manufacturing sector for the production of various products such as automotive parts, kitchen appliances, machinery components, and construction materials. The high corrosion resistance and durability of stainless steel make it an ideal choice for these applications. 2. Construction industry: Stainless steel coils are widely used in the construction industry for applications such as roofing, cladding, structural supports, and reinforcement. The strength, resistance to harsh weather conditions, and aesthetic appeal of stainless steel make it a popular choice in architectural designs. 3. Food processing industry: Stainless steel coils are commonly utilized in the food processing industry for equipment such as food storage tanks, conveyors, and processing machinery. Stainless steel's hygienic properties, resistance to corrosion, and ease of cleaning make it suitable for maintaining the purity and safety of food products. 4. Chemical industry: Stainless steel coils find extensive usage in the chemical industry due to their excellent resistance to corrosion from chemicals and harsh environments. They are used in the production of storage tanks, pipelines, and reactors that handle various chemicals and corrosive substances. 5. Energy industry: Stainless steel coils are widely employed in the energy sector for applications such as power generation, oil and gas exploration, and renewable energy systems. They are used in heat exchangers, turbine components, pipelines, and offshore structures due to their high resistance to corrosion, strength, and longevity. 6. Medical and pharmaceutical industry: Stainless steel coils are commonly used in medical and pharmaceutical applications due to their biocompatibility and resistance to corrosion. They are used in the production of surgical instruments, medical implants, and medical equipment that require sterilization and durability. 7. Automotive industry: Stainless steel coils are utilized in the automotive sector for various components like exhaust systems, fuel tanks, catalytic converters, and structural parts. Stainless steel's high heat resistance, strength, and resistance to corrosion and oxidation make it suitable for these applications. These are just a few examples of the wide range of applications of stainless steel coils. Their versatility, durability, and resistance to corrosion make them indispensable in numerous industries where reliability and longevity are crucial factors.

- Q: How much should someone sell a 6 ft stainless steel counter? How about one with a sink?

- Ask for the best offer on OKorder and find out.

- Q: How are steel coils used in the manufacturing of shipbuilding?

- Steel coils are used in shipbuilding to create various components and structures. These coils serve as a primary material for fabricating ship hulls, decks, bulkheads, and other structural elements. They are typically cut, bent, and shaped to fit specific design requirements, providing strength and durability to the ship's construction. The steel coils are also often used to produce pipes, cables, and other fittings essential for the ship's mechanical systems. Overall, steel coils play a crucial role in the manufacturing of ships, ensuring their structural integrity and seaworthiness.

- Q: I need to know what steel's weakness is.

- look okorder

- Q: Hey everyone.I have a whetstone and a honing steel. I purposely tried to make one of my knives less sharp twice to see how well the whetstone and honing steel would work.It even seemed that when I was using my whetstone it wasn't as sharp as it was when I used my honing steel, but when I also used my honing steel after having sharpened my knife on the whetstone, it was razor sharp.I was wondering, is the whetstone only supposed to be used when the knife edge isn't as flat anymore or something? Like, only when it doesn't really have an edge anymore?Please explain your answer.Thanks everyone.

- In general, whetstones will actually remove metal in order to sharpen a blade, and the angle they're used at is important too. A steel will just straighten the blade between uses, not actually remove metal. The effect is to make it sharper than it was just before, but only because it's straighter. Using a knife makes the very thin edge kind of flatten or even fold over a bit, or get wavy, etc...so the steel just straightens it back out (imagine what happens when the very thin blade gets pressed down repeatedly on a cutting board, or even cuts through foods repeatedly). (A whetstone is used only when steeling finally just isn't enough to get the blade sharp as needed.) .

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve assessing the extent of the damage, ensuring proper safety precautions are in place, and following industry best practices for handling and storing damaged coils. It is important to inspect the damaged coils for any potential hazards, such as sharp edges or protruding objects, and to use appropriate lifting equipment and protective gear when moving or transporting them. Additionally, damaged coils should be segregated from undamaged ones to prevent further deterioration and potential safety risks.

Send your message to us

galvanized steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t. m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords