Aluminum Diamond Plate Sheets Lowes 0.1-16mm Aluminum Alloy Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

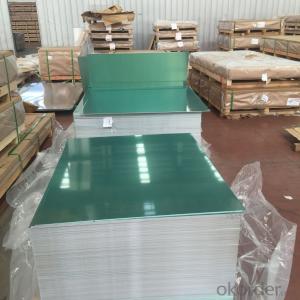

1.Dark green surface, color changed into light green after exposure.Image checked easily.

2.Surface Quality :be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3.Faithful reproduction capacity, result at clear images.

4.Highly durable, long impression available.

5.Excellent sensitive character.

6.Resolution : 2%-98%

7.Material:1050/1060/1070/1100/2A16/2A06/2A12/2024/3003/3A21/4A01/5052/5005/5083/5A05/6061-T6/6063-T5/6082/7021/7075-T6/8011,etc

8.Certificate: ISO9001:2000, SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO)

9.Packing:First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation,wooden pallets

10.Application:Aircraft, automobile, train,Building wall, ceilings, roofing, furniture cabinet, lighting plate,etc

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- When aluminum reacts with hydrochloric acid heat is produced as well as aluminum chloride. This heat is warming up the HCl, which you should remember is a gas dissolved in water, a little of which evolves from the water. You're smelling HCl gas. There shouldn't be any dense white smoke, unless you've got an open container of ammonia nearby. In that case the smoke is particulate ammonium chloride, produced by the reaction in the air of HCl and NH3.

- Q: how to connect copper pipe and aluminum sheet?

- it depends on the size and requirement, we can use ultrasonic wave rolling welding to connect copper pipe and aluminum sheet.for example, solar energy radiator-fan contains connection of copper pipe and copper sheet, ultrasonic wave rolling welding equipment is used here.ultrasonic wave welding of metals is suitable for the welding of copper to copper, copper to aluminum and aluminum to aluminum.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags.

- Q: What are the different surface finishes available for aluminum sheets?

- Some of the different surface finishes available for aluminum sheets are mill finish, brushed finish, anodized finish, and embossed finish. Mill finish is the natural appearance of the aluminum without any additional treatment. Brushed finish involves brushing the surface to create a textured appearance. Anodized finish involves an electrolytic process that forms a protective layer on the surface and can be colored. Embossed finish involves creating patterns or designs on the surface using pressure or heat.

- Q: Are aluminum sheets suitable for medical equipment?

- Medical equipment can indeed utilize aluminum sheets. Aluminum, a lightweight and durable metal, is highly resistant to corrosion, making it a popular choice in the manufacturing of medical equipment. Surgical instruments, diagnostic tools, and patient monitoring systems all benefit from the use of aluminum. The malleability of aluminum sheets allows for the creation of intricate designs in medical equipment fabrication. Furthermore, aluminum is non-toxic and non-magnetic, both of which are crucial qualities in medical environments. Its ability to withstand sterilization processes, like autoclaving, only adds to its suitability for medical equipment. Overall, aluminum sheets prove to be a dependable and adaptable material for the production of medical equipment.

- Q: Are the aluminum sheets suitable for electrical conductivity applications?

- Yes, aluminum sheets are suitable for electrical conductivity applications. Aluminum is a highly conductive material, with an electrical conductivity approximately 61% that of copper. This makes it a popular choice for various electrical and electronic applications where conductivity is important. Aluminum sheets are used in the construction of power transmission lines, electrical cables, bus bars, and heat sinks, among others. Additionally, aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which further enhances its suitability for electrical conductivity applications.

- Q: Which is better aluminum or stainless steel?

- Depending on what your using it for. Stainless steel is much stronger in strength seeing Aluminum has it's weak points and can bend under stress, and is also weak under large amounts of heat. I use stainless steel bolts and nuts for my exhaust systems, and starters on my truck, and they still haven't rusted as of yet.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- Brake cleaner will stain. You need to go to a local auto parts store, like Pep Boys, or Autozone and get a container of Mother's aluminum wheel cleaner and polish. Then go into the aisle with the rags and get a bundle of terry towels and a bundle of baby diaper towels. You will need to use the cleaner/polish on the terry towels first and work in a circular motion, and don't be afraid to apply pressure. You will start to see the cleaner working when it starts turning black, DONT QUIT YET, continue working in a circular motion, and keep at it. After you are happy with the look of the aluminum use the baby diaper towels and wipe them clean in a circular motion also. You may have to repeat to get the desired effect, but in no time your wheels will look like new (or even better)! I have personally hand polished out many small parts, and even the radiator in my 63 impala (which was raw aluminum) with this stuff and it really works.

Send your message to us

Aluminum Diamond Plate Sheets Lowes 0.1-16mm Aluminum Alloy Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords