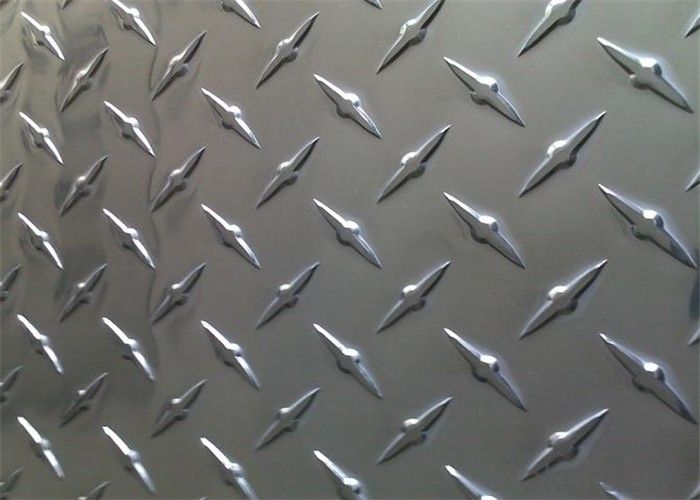

Large Aluminum Foil Sheets - 1.5mm AA1100 H16 Colored Embossed Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alloy | 1. A1050 , 1060 1100 |

Temper | 1. O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38/H114 |

Width | 500-2200mm |

Length | 500-10000mm |

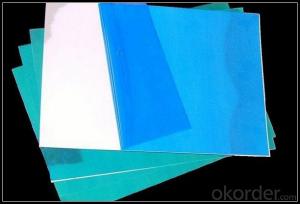

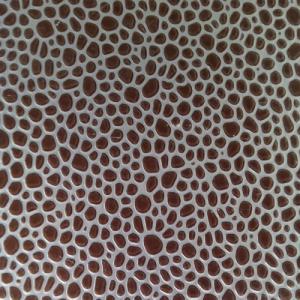

Surface | Bright , Mill finish,Color Coating, PE & PVC Coated |

Metal powder coating entails:

1.) Part preparation (pre-treatment)

2.) Application of powder

3.) Curing

The Properties of 5052 Aluminum disc:

1.Alloy 1050 1060 1100 1200 3003 3004 3105 5052 5005 5754 aluminium disc, deep drawing quality, good spinning quality, excellent forming and anodizing, no four ears.

2.Excellent reflectivity, good for Polishing.

3.Good anodized quality, suitable for hard anodizing and enameling.

4.Clean surface and smooth edge, hot rolled quality, fine grains and after deep drawing no looper lines.

5.Excellent pearl color anodizing.

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: Can aluminum plate resist acid and alkali?

- Aluminum is a more active metal, easy to react with the acid and alkali of the outside world. If it is in water for a long time, aluminum will react with acid and alkali substances in water. How to improve the acid and alkali resistance of aluminum alloy?Mainly through the oxidation of aluminum alloy, so that its surface with a layer of oxide film, to prevent the external acid-base substances on aluminum alloy corrosion.In order to reduce the surface hardness and wear resistance of aluminum alloy and prolong its service life, the surface oxidation surface treatment technology has become an indispensable part of the use of aluminum alloy.

- Q: How could two pieces of aluminium flakes be welded together?

- its welding strength is very high. you can use the following methods to weld two pieces of aluminum sheets together: 1, strict deformation control requirement. 3, it can prevent some flux remnant during welding. 3,the welding wire welding of low temperature M51 and M51-F is operated under 179?C.or they are welded in the situation of being especially thin.4, it can solve the welding of 3 series aluminium alloys and casting, and its welding temperature is 380-400?C.its advantage is that you don't need any flux during welding. WE53 low temperature aluminium welding wire has a high affinity in welding 7 series aluminium alloys. and Q303 low temperature aluminum welding wire has a high affinity for the welding of 1 series aluminium alloys, die casting or 6 series welding materials.

- Q: 1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- 1) Aluminum forms a natural oxide coating in air that is very unreactive, so when you put it from air into water, nothing happens. 2) Mercury chloride reacts with the aluminum to form an amalgam (mercury-aluminum alloy) and is very reactive. 3) Amphoteric behavior 4) No idea. Check you textbook or class notes. 5) No idea. 6) To form aluminum sulfate

- Q: Are aluminum sheets suitable for reflective signage?

- Indeed, reflective signage can effectively utilize aluminum sheets. This adaptable material is frequently employed for such signs because of its resilience, lightness, and capacity to reflect light. With a noteworthy reflectivity index, aluminum proves itself ideal for situations where visibility is of utmost importance, such as road signs, traffic signs, and safety signs. By applying reflective films or paints to aluminum sheets, their reflective properties can be further enhanced, guaranteeing optimal visibility even in dimly lit environments. Furthermore, aluminum's resistance to weathering, corrosion, and fading ensures that it remains a durable and economical option for reflective signage in the long run.

- Q: Can aluminum sheets be used for automotive body panels?

- Certainly, automotive body panels can indeed utilize aluminum sheets. In reality, the automotive industry is progressively incorporating aluminum due to its lightweight attributes and remarkable strength-to-weight ratio. By employing aluminum sheets for body panels, the overall weight of the vehicle is diminished, thereby enhancing fuel efficiency and performance. Moreover, aluminum exhibits exceptional resistance to corrosion, rendering it an enduring selection for automotive purposes. The use of aluminum sheets for automotive body panels has gained considerable popularity, particularly in the manufacturing of electric vehicles, as their lightweight structure optimizes the vehicle's range.

- Q: Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- Brothers, there are several kinds of bubble gum, first to check is not part of the foam glue strip plug is not good, should be smooth, playing in a plastic bubble, not to leave the air, also can't have water, air water will bubble. In addition, glue when the temperature is very important no, when hot hit. Glue master experience play a decisive role, there is a great work in absolute don't let coolie, evenness and speed are very important.

- Q: Are aluminum sheets suitable for HVAC systems?

- Yes, aluminum sheets are suitable for HVAC systems. Aluminum is a lightweight and durable material that provides excellent thermal conductivity, making it ideal for use in HVAC systems. It is commonly used for making ductwork, heat exchangers, and fins in air conditioning units. Aluminum sheets are corrosion-resistant, which is advantageous in environments with high humidity or exposure to moisture. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for HVAC systems. Overall, aluminum sheets offer numerous benefits and are widely used in the HVAC industry.

- Q: I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- Lydney Aluminum, I don't think that I have heard of them in the boating industry. T.

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated.

Send your message to us

Large Aluminum Foil Sheets - 1.5mm AA1100 H16 Colored Embossed Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords