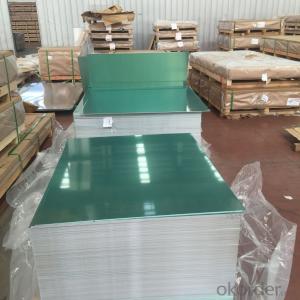

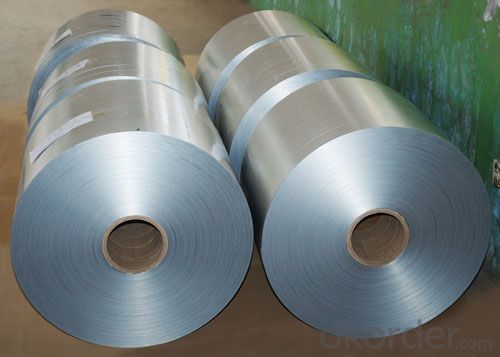

Lennox Aluminum Coils 5083 H112 / H116 6063 Aluminum Sheet Plate 0.1-16mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5083 H112 / H116 6063 Aluminum Sheet Plate 0.1-16mm

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: What are the production processes of aluminum coil and what are the functions of various industrial furnaces in the production of aluminum? The more detailed, the better. Thank you! Points!

- There are aluminum annealing furnace, aluminum alloy quenching furnace, aging furnace and smelting furnace.

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Yes, aluminum coils can be used in the production of heat exchanger fins.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q: Is it possible to utilize steel wires in the creation of jewelry or decorative items?

- <p>Yes, you can use steel wires for making jewelry or decorations. Steel wires are durable and can be shaped into various forms, making them suitable for a range of designs. They are often used in wire wrapping techniques and can be combined with beads or other materials. However, it's important to consider the type of steel used; stainless steel is more resistant to rust and is commonly preferred for jewelry making. Additionally, steel wires may require special tools for cutting and bending, and proper safety measures should be taken during the crafting process.</p>

- Q: What are the steps to properly store an unused aluminum coil to prevent it from rusting?

- <p>To store an unused aluminum coil and prevent rusting, follow these steps: 1. Clean the coil thoroughly to remove any dirt or moisture. 2. Apply a thin layer of a rust inhibitor or light oil to the surface. 3. Wrap the coil in a protective plastic or wax paper to prevent moisture and air exposure. 4. Store the coil in a cool, dry place away from direct sunlight and humidity. 5. Ensure the storage area is well-ventilated to prevent condensation. 6. Periodically check the coil for any signs of rust and clean if necessary. By following these steps, you can effectively prevent rusting and maintain the quality of the aluminum coil.</p>

- Q: What are the differences between aluminum coil 3003h24 and 3a21h14?

- The mechanical property references of rolled plate 3003 H24and 3A21 H14 are as follows: 3003 H24--Rm/MPa≧140-180;Rp0.2/MPa≧115;A(%)≧1-5(thickness 0.2mm-4.5mm)3A12 H14--Rm/MPa≧145-215;A(%)≧6

- Q: Are there any specific installation requirements for aluminum coils?

- Yes, there are specific installation requirements for aluminum coils. When installing aluminum coils, it is important to consider a few factors. Firstly, it is crucial to ensure that the coils are properly supported and secured during installation. Aluminum coils can be quite heavy, so adequate support is essential to prevent sagging or damage. This may involve using appropriate brackets or support structures to ensure the coils are securely mounted. Secondly, it is important to consider the location and environment where the coils will be installed. Aluminum coils are often used in HVAC systems, and it is crucial to ensure that the installation area is free from any corrosive substances or chemicals that could potentially damage the coils. Additionally, proper ventilation should be provided to prevent any buildup of heat or moisture, which can affect the performance and lifespan of the coils. Furthermore, it is essential to follow the manufacturer's guidelines and recommendations for installation. This may include specific instructions regarding the type of fasteners or connectors to use, proper spacing between coils, and any other specific requirements for the particular aluminum coil being installed. Adhering to these guidelines will ensure the optimal performance and longevity of the coils. Lastly, it is highly recommended to have the installation of aluminum coils carried out by a professional who is experienced in handling and installing these components. This will ensure that the installation is done correctly, minimizing the risk of any issues or damage that may arise from improper installation. In summary, specific installation requirements for aluminum coils include proper support, consideration of the installation environment, adherence to manufacturer guidelines, and professional installation. Following these requirements will help ensure the optimal performance and longevity of the aluminum coils.

- Q: What is the temperature range within which aluminum coil can be used?

- <p>Aluminum coil can be used within a wide temperature range, typically from -200掳C to 150掳C. At low temperatures, it retains good ductility and strength, while at higher temperatures, it maintains its form and conductivity. However, it's important to note that prolonged exposure to temperatures above 150掳C can lead to a loss of mechanical properties over time. Always refer to specific product data sheets for precise temperature limits.</p>

- Q: What are the potential health risks associated with aluminum coils?

- Aluminum coils find common usage in HVAC systems due to their durability and excellent heat transfer properties. Although they are generally regarded as safe, there exist potential health hazards associated with aluminum coils if specific conditions are not met. One primary concern is the possibility of aluminum leaching into the air or water supply. Aluminum is a known neurotoxin, and prolonged exposure to it can result in various health problems, especially in individuals with pre-existing conditions like kidney disease or weakened immune systems. However, the quantity of aluminum that typically leaches from coils is minimal and unlikely to pose a significant risk to most people. Another potential health hazard pertains to the buildup of dust, dirt, and other particles on the aluminum coils. These particles can serve as a breeding ground for bacteria, mold, and other allergens, negatively impacting indoor air quality. If not adequately maintained and cleaned, these contaminants can lead to respiratory issues, allergies, and even infections in susceptible individuals. Moreover, aluminum coils can generate electromagnetic fields (EMFs) due to the electric currents passing through them. While the health effects of EMF exposure are still subject to ongoing research, certain studies indicate a potential connection between high levels of EMFs and specific health conditions, including cancer. However, it is essential to note that the levels of EMFs emitted by aluminum coils are generally deemed to be within safe limits and unlikely to present significant health risks. To mitigate these potential health hazards, it is crucial to ensure proper maintenance and cleaning of aluminum coils. Regular inspections, professional cleaning, and frequent air filter changes can help prevent the buildup of contaminants and maintain good indoor air quality. Additionally, it is advisable to consult with HVAC professionals to guarantee proper installation and maintenance of the coils, minimizing the risk of aluminum leaching or excessive EMF exposure. In conclusion, although potential health risks are associated with aluminum coils, they are typically considered safe when adequately maintained. By taking necessary precautions and adhering to recommended maintenance practices, it is possible to minimize any potential health concerns related to aluminum coils in HVAC systems.

- Q: What are the common international standards and certifications for aluminum coils?

- Some common international standards and certifications for aluminum coils include ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and ISO 45001 (Occupational Health and Safety Management System). Other certifications specific to aluminum coils may include ASTM (American Society for Testing and Materials) standards and certifications from industry associations such as the Aluminum Association.

Send your message to us

Lennox Aluminum Coils 5083 H112 / H116 6063 Aluminum Sheet Plate 0.1-16mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords