ZYC series ZYC700B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

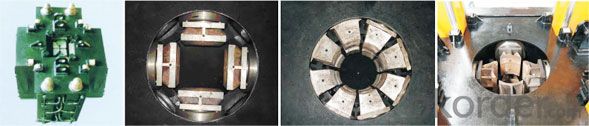

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 700 | suitable pile & specification(mm) | ¢300-800 | |

| Max. Piling speed(m/min) | 5.9 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 2.0 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | / | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | / | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 14.2/19.4 | |

| Max.rotation angle per time(°) | 11 | Weight composition | (t) Machine weight | 170±3 |

| Rated hydraulic system pressure(mpa) | 25(20) | Added water weight(t) | 48 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 482 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 700 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: I'm a rural resident, close to the town;A building will be built behind my house and the pile driver is only 10 meters away from my house..Although the use of hydraulic pile driver, there is no sound like that. There was no sound at all, but every time they moved the pile, it was going to be a big shock, and my house was shaking badly. I'm very upset, and I don't know if there is any influence on the house, the dirt and the ground because of the driving at such a short distance..My country's rural housing is three storey building, two house facade, 8 meters wide or so, built in 92 years.So I specifically asked about the laws and regulations on the construction of pile driving and future formal construction of the surrounding residential housing what protective provisions?Thank you

- You should say is static pressure pile, is the smallest influence of all the filling pile, if it is immersed pipe pile will not, the safety distance is 28 meters

- Q: How much can a pile driver make in a year?

- Hello Can contact Huilong spiral drill, rotary drilling is burning diesel, the average is 40 or so, to see what much of the diesel engine, what brand of Oh ~ what needs, you can consult a wylong machinery in Hunan!

- Q: How many hydraulic pile drivers or diesel pile drivers are used in high-rise residential buildings?

- Diesel hammer pile machine imports (mostly self-propelled) and domestic two categories, according to pile hammer points from 1T to 8T range; the corresponding price is very different, domestic about 40-80.

- Q: What is the starting current for a 55 kW pile driver? What's the big leakage switch, please?

- In addition, there are friends who recommend you to use the "people" brand, the people of this brand, there are three in China, namely: the people of Shanghai, the people of Beijing and the Chinese people. Of these three brands, the people of Shanghai are the best. Besides, Changshu switches are also good.

- Q: How much voltage does a tower crane need, and how much voltage does the 160A meter equal?

- The site of the hydraulic piling machine and crane are in need of three-phase power supply of 380/220V, the general piling machine power is about 40KW, the crane power is about 70KW, so probably need 110~130KW power, three-phase 160A meter can take 105KW, general electric meter overload ability than the wall, with 1 sets of hydraulic piling machines and 1 sets of tower crane very reluctantly can.

- Q: All say that it is a solid foundation, anti settlement, but what is the specific principle of the ah? To the ground where a few concrete pillars will be able to prevent settlement?

- It supports the whole building. (some very it takes long, the friction between the pile and soil to provide capacity, do not need to enter the good earth.)And in the composite foundation pile, cement mixing pile, such as fly ash gravel pile, equivalent is used to reinforce the foundation.

- Q: How much is a steel sheet pile driver?

- According to the machine model, 8-10 or so, no oil, with the driver and a worker.

- Q: Want to buy a small pile driver, I do not know whether it is good track or wheeled good?

- The track is better, the practicability is very wide, not stuck in the mud, and the good wylong machinery!

- Q: What is the noise of a static pile and a diesel pile driver?

- The noise of the static pile is small, so it is suitable for the construction in the city and the construction cost is higher.The diesel pile driver has large noise and is suitable for field construction, and the construction cost is low.

- Q: The principle of pile driver

- (3) vibration hammer. Using the mechanical vibration force of the pile hammer to make the pile sink into the ground, it is suitable for carrying less precast concrete pile, steel sheet pile and so on.(4) static pile pressing machine. Produced by mechanical hoist or the pressure of the hydraulic system, the pile in the hydrostatic pressure under the action of pressure in the soil, various types of precast pile used in general bearing capacity.

Send your message to us

ZYC series ZYC700B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords