ZYC series ZYC500B-B Multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

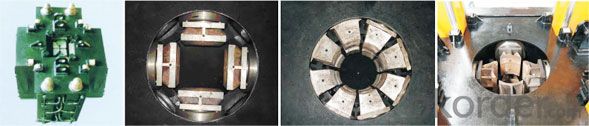

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 500 | suitable pile & specification(mm) | ¢300-600 | |

| Max. Piling speed(m/min) | 6.5 | Max. Crane lifting weight(t) | 16 | |

| Piling stroke(m) | 1.8 | Hanging pile length(m) | 15 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1380 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2800 | |

| Max. Rise stroke(m) | 1.1 | Intensity of pressure(tf/m²) | 12.5/15.0 | |

| Max.rotation angle per time(°) | 11° | Weight composition | (t) Machine weight | 158±2 |

| Rated hydraulic system pressure(mpa) | 23(20) | Added water weight(t) | 36 | |

| Hydraulic Pump (Unit × Ml/Turn) | 3×80 + 1×80 | Counter weight(t) | 306 | |

| Motor power (Unit × kw) | 3×37 + 1×30 | Total weight(t) ≥ | 500 | |

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q: How many meters can a small pile driver reach?

- The maximum diameter of the pile driver is 1.2 meters

- Q: Is there a pile driver in it?

- There's one in the neighborhood. Can find other counterparts to learn, skilled in their own open. However, the piling machine is not stable, but also a team together. And we're going out of town, this month, ten days.

- Q: Advantages and disadvantages of pile driving methods

- Here are some of the advantages and disadvantages of the above methods:Hammer method:The method is simple in construction, small in investment and convenient in construction, and has been widely used before.But there is a cut that doesn't go around. It's too noisy and doesn't work in hard soil or soft soil. It's being phased out.Static pile:Use the static pressure to press the pile into the ground, no vibration and no noise during construction. Applicable to weak soil and adjacent to the construction of structures that are afraid of vibration.But when there is a sandwich of medium thick sand with thickness greater than 2m, it is not suitable to use the static pressed pile. And there is soil squeezing effect.Vibration method:The vibration hammer is lifted to the top of the pile, pile head is connected with the vibration box pile cap or hydraulic pile clamping device for clamping, the exciting force generated by the vibration hammer pile to soil vibration, friction force between soil particles is greatly reduced, the pile under the action of self weight and mechanical force into the soil.The vibrating pile driving equipment has the advantages of simple structure, convenient operation and high efficiency. Suitable for heavy steel sheet pile, steel pipe pile and the length within the 15m slender reinforced concrete precast pile in the sand in the highest efficiency, poor little clay.

- Q: Piling of percussive drilling

- 7, the drilling process control should be rigorous, but also do not have to worry about failure, a reasonable choice of treatment methods, generally can be solved, the common, foot blade perforation, hole collapse, partial hole, cross hole, drilling, drilling, drilling buried crane, well preventive measures are generally not in advance, very important duty responsibility. 8, the remaining holes, steel cage decentralization, concrete pouring, sealing and other are more conventional, do not write more. But the bottom of the hole, sediment, sediment, etc. must be recycled clean, otherwise it will be buried in the later works of greater risk. When the concrete is poured, the bottom concrete under the impact of residue inclusion in steel or bond caused by defects in the pile in concrete, on the upper structure of the load transfer to the bottom of the pile, the structure will definitely should produce uneven settlement for residue.

- Q: What's the prospect of a small pile driver?

- Is it for architecture? It should be OK. Development is the eternal trend

- Q: What about the engine power of a hydraulic pile driver?

- The utility model has the advantages of stable performance and reliable use, and can be used for self loading, self unloading and moving transition. During transportation, the upper section of the main frame can be retracted and folded, thereby saving a great deal of expenses and troubles in lifting and dismounting. The pile machine is not only efficient, economical and practical, it is the best choice for customers, but also can adapt to various bad weather and working conditions of the operating environment.

- Q: I can drive an excavator and a hammer, but I want to learn how to drive a pile driver. How long will it take to learn?

- Very quickly, understand the working principle, work methods, basically on the line

- Q: Handan steel sheet piling machine a number of how much money

- Trough steel sheet pile 9m 200-300Reference data: 80 tonsI know the construction data, quasi quasi reference

- Q: AMD FX 8350 eight core CPU AM3+ piling machine and tin box what is the difference between the master pointing

- All one to。 Most of the cartons were in 2013. But in 2012, they were all iron boxes. And the radiator of the paper box doesn't have the radiator of the iron box. Although the AMD platform U original box radiator is no use. But I always feel sick. Bought on Jingdong.

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 19, the operation should always check whether the fasteners are loose, the moving parts are flexible. Diesel pile hammer after the operation note 20 after the operation, diesel hammer should be parked in a solid flat ground, diesel hammer should be placed on the ground plate or into underground pile, shutting down the fuel switch, barrel type hammer should be put in the net cooling water, mounted on the cylinder head, exhaust cover, safety screw etc., and mounted on the safety card. The pile holder shall be placed in a stop position, locking the safe and braking position. 21 rail type pile holder should clamp the rail clamp when it is not working. When the 22 pile stand is broken, the brake performance of the hoister shall be checked first, and then operated according to the procedures specified in the instruction manual. 23, long-term disabled, should be unloaded diesel hammer, loaded with safety board, the diesel hammer fuel, lubricating oil and cooling water all out, cleaning the combustion chamber, coated with anti rust oil on the ball bowl, and take rainproof measures.

Send your message to us

ZYC series ZYC500B-B Multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords