Pile Driver (DPD Fixed Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pile Driver (DPD Fixed Clamp Type Series)

-Proven economic feasibility, mobility, safety

-360 degrees rotation devices of middle brackets

SHEET PILE DRIVER (GENERAL TYPE)

DPD Fixed Clamp Series - DPD350

- 360 degrees rotation of middle bracket

- Proven economic feasibility, mobility, safety

- Driving & Extraction sheet pile, tube, H-beam

- Most representative hydraulic vibro hammer

- Suitable equipment for construction working site

Excellent performance and mechanisms without power pack.

Proven workability: With the advantage of the excavator’s mobility, High performance operation at overpasses, under high voltage lines, on bridges and populated cities.

-Maximized the life of the equipment by using a special bearing designed for high frequency

-Best quality of Cushion elastomers are adopted in order to isolate vibration being transmitted to excavator.

-Easy installation using breaker hydraulic line of the excavator with electric cable device and operation control

-Mounting and dismounting can be easily done at all times

-The upper body allows 360 degree free rotation for easy operation and automatically anchors itself during operation

-Sheet pile, H beam and tube can be used by hooking up a wire on the main body of pile driver

-Double clamping devices can be fitted for pipe driving and extracting (Option)

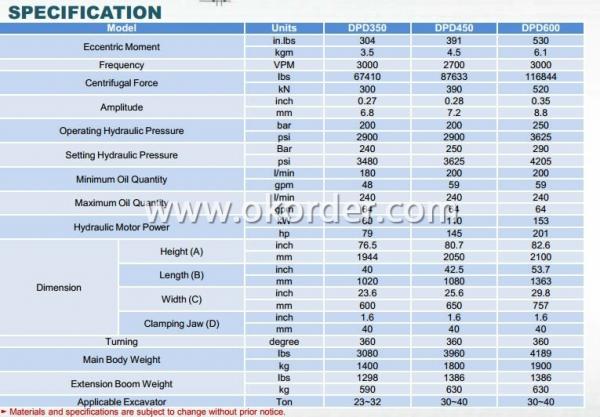

Specification of Pile Driver (DPD Fixed Clamp Type Series)

- Q: If so, ask what it works forThe pile hammers I've seen before all have a steam hammer, and this one doesn't know how it works.

- Static pressure pile machine, the static pressure construction relies entirely on the hydraulic static pressure to push the pile into the ground. It's like nailing a nail into a wood, the jacked machine is pushing the nail in directly, and the other kind of diesel hammer can be seen as hammering in.

- Q: The working principle of a pile driver ship

- The pile hammer is attached to two parallel vertical guide rods at the front of the pile support frame and is hoisted by the pile frame, and the front of the pile support is provided with a guide frame.

- Q: There are also some related costs. Originally wanted to buy a pile driver, the budget of 100-200. I hope my friends will give me some advice.. Thank you

- Depends on what project you do, if there is no noise requirements, diesel hammer piling machine is better, a price at about 500000, back to Ben faster. The hydrostatic press is a bit heavy.

- Q: Is the spiral pile driver still being dug? Is it easy to operate? How many people do you need?

- Shandong strong pile driver without manual shovel, the operation panel is very simple, a day will be able to operate skillfully, an operator can work, save worry and effort.

- Q: Why should I pull it up a few times? Because the friction should stop gradually

- The working principle of diesel hammer, hammer force pull up several times in the ignition, ignition after diesel combustion explosive can put the hammer from the top, the hammer reaches a certain height to fall under gravity, in the moment of contact pressure the light diesel (compression diesel can make its combustion is its characteristics), and was the top hammer, again and again.

- Q: How deep can a pile driver work?

- The deepest foundation piling machine can hit 20 meters, five or six floors are generally enough, in a special customer service Huilong piling machine three insurance contract, you can personally to visit the company, can also visit the construction site.

- Q: Which is better for the building foundation treated by a pile driver and a rammer?

- Compaction can not deal with: 1. around the fear of loess foundation soft soil /2. /3./ fall of vibration building. But the cost is cheap. The long-term effect is good.Piling can basically cope with any situation, but the cost will be high

- Q: I can drive an excavator and a hammer, but I want to learn how to drive a pile driver. How long will it take to learn?

- Very quickly, understand the working principle, work methods, basically on the line

- Q: What are the types of hammer pile drivers?

- There are diesel tube pile driver, power source brand, Zhong Zhong brand, and Zhejiang is very popular guide rod hammer

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 11 water cooled diesel hammers shall be maintained with sufficient cooling water for continuous work and shall not be used without water. 12 operation, diesel hammer final ten hit penetration should comply with the provisions of the use manual, when every ten hit penetration is less than 20mm, should stop hammering or replace pile hammer. 13 during the piling process, lubrication and repair shall not be performed. 14 when the hammer (pile) of pile driver is used, the minimum distance of hammer (pile) from the top of column shall be ensured. 15 after the pile is inserted, the verticality of the pile should be corrected in time. When the pile is embedded in the 3M, the pile should not be taken for walking or turning to correct it. The 16 batter pile, the vertical pile should be vertical, the pile into fixed, and then began to tilt, tilt 18.5 degrees in the post, should not raise diesel hammer. Track three fulcrum type pile frame in the backward of batter pile, should use the rear leg cylinder; track type pile frame should be increased after the support platform, and clamping rail clamp. 17 when driving, the diesel hammer shall be lowered to the lowest position, and the slope shall be in accordance with the instruction manual. Self propelled pile drivers should be manned by hand. When walking on the ramp, the center of gravity should be moved to the top of the ramp. The distance from the pipe type piling machine to the end of the roller tube shall not be less than 1m. 18 during operation, the slewing brake should be slow, and the track type and walking type pile stand shall be turned in the same direction, not more than one week.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pile Driver (DPD Fixed Clamp Type Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords