ZYC series ZYC40B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

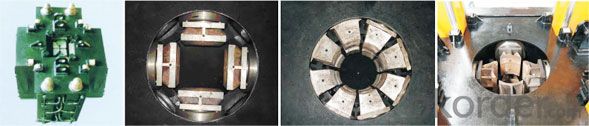

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 40 | suitable pile & specification(mm) | 200-250 | |

| Max. Piling speed(m/min) | 4 | Max. Crane lifting weight(t) | 3 | |

| Piling stroke(m) | 1.2 | Hanging pile length(m) | 7 | |

| Max. Longitudinal pace(m) | 1.4 | Minimum side piling space(mm) | / | |

| Max. Transverse pace(m) | 0.26 | Minimun corner piling space(mm) | / | |

| Max. Rise stroke(m) | 0.6 | Rated hydraulic system pressure(mpa) | 15(14) | |

| Intensity of pressure(tf/m²) | 9.3/11.8 | Weight composition (t) | Host machine(t) | 23±1.0 |

| Hydraulic pump (Unit × Ml/Turn) | 1×63 + 1×25 | Counter weight(t) | 17 | |

| Motor power (Unit × kw) | 1×63 + 1×25 | Total weight(t) | 40 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

1.Reply your inquiry in 24 working hours.

2.Experienced staffs answer all your questions in professional and fluent English.

3.Customized design is available. OEM is welcome.

4.Exclusive and unique solution can be provided to our customer by well-trained and professional engineers and staffs.

5.Special discount and protection of sales area provided to your distributor.

6.Do the best reliable heavy-duty single drum vibratory road roller in China.

7.Warranty period is 1-year or 1500 working hours against Bill of Lading.

- Q: Which price is low for a pile driver?

- Specializing in sales of steel sheet pile, steel sheet pile construction, leasing, model complete, high quality, the construction of steel sheet pile, the price is more favorable, and exquisite design, honest and trustworthy business purposes, in full accordance with the market-oriented, large-scale, standardized operation requirements specification, through the implementation of brand strategy to build the core competitiveness of enterprises

- Q: What is the power of the pile driver?

- Hello, there are many kinds of power in the pile driver. How big do you need?.

- Q: I can drive an excavator and a hammer, but I want to learn how to drive a pile driver. How long will it take to learn?

- Very quickly, understand the working principle, work methods, basically on the line

- Q: Does the mud come up with the shovel? Can you tamper with a stone? 1.2 traction? How many meters per hour can the ramming mud fall? And the price of the equipment! It's better to have a talk with that big brother! Thank you on your knees

- 80 generally refers to the 456080 common hammer and so on is 60 of the hammer that I is the 60 80 hammer is not a lot of major areas this is not to say the price is equipped with 80 hammer down the price is a full set of 45W-50W including the hammer cable wire rope mechanical appearance does not include cable wire rope.

- Q: Why do some people need to dig the foundation and pile it up to dig a hole?

- First of all, depends on the type of your pile, prefabricated or bored pile.If it is a bored pile, then it is obvious to dig first.If it is a prefabricated pile, then pile it directly, then dig it.

- Q: Can the piling machine be built at night?

- In principle, it is not allowed to work at night, unless it does not affect anyone's life, study and work, and does not constitute noise pollution.

- Q: Such as the title... Phenomenon: quiet with a sound to length, rises again, continuous... Better knowledge about this point for more,...

- This is a hammer driven pile driver that uses diesel fuel to ignite, hammer upward, then drop free, and pile the pile by gravity. Generally used for concrete precast pile and steel pipe pile and so on.

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 1, the pile driver walking and slewing, hanging pile, hammer should not be carried out simultaneously. The pile driver shall not turn or walk in full swing after hanging the pile. 2 Side Piling and long distance pulling pile are not allowed in pile driver. When the pile is hoisted in front, the horizontal distance of concrete shall not be greater than 4m, and the steel pile shall not be larger than 7m, and the pile shall be prevented from colliding with the post. 3 when the column is turned into place and the column is locked, the piling frame of the double guiding post can be operated. 4 before the start of the diesel hammer, the pile hammer, the pile cap and the pile should be on the same axis, and shall not be driven by eccentric piling. 5 in soft soil pile driving, should first close the throttle, cold beat, to each attack penetration is less than 100mm, can start the pile hammer. 6 after the start of the diesel hammer, the landing gear should be lifted. The distance between the landing gear and the top of the cylinder of the cylinder hammer shall not be less than 2m during the hammering process. 7 when the diesel hammer is running, the jumping height of the impact part shall be visually observed, and the requirements of the instruction manual shall be strictly enforced. When the required height is reached, the throttle shall be reduced and the stroke of the impact part shall be controlled. 8 during the operation, attention should be paid to the change of the soil layer and the operation of the pile driver, and the necessary measures should be taken in time. 9 diesel hammer appear early ignition, should stop working, according to the instructions for processing. 10 when the piston jumps on the cylinder hammer, the grease should be observed to flow out of the drain hole. The lubricating oil of the lower piston shall be filled according to the instruction manual.

- Q: What machinery is suitable for a PV pile driver?

- Are you talking about a small hammer pile driver for excavators? If you are playing a photovoltaic pile (hollow pipe pile) below 9 meters,

- Q: What machinery is used for piling?

- In fact, in some places with artificial, you can go to buy a wylong machinery piling machine equipment is good, driving fast and convenient and money

Send your message to us

ZYC series ZYC40B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords