Drilling Rig for Construction of SMWBored Pile Drilling Rig

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drilling Rig for Construction of SMWBored Pile Drilling Rig

Product Features:

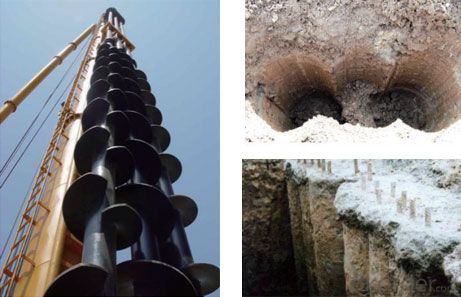

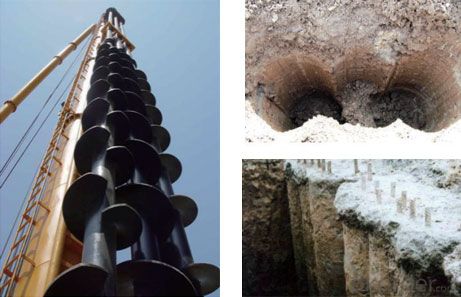

| SMW, which is short of Soil Mixing Wall, is a construction method developed in Japan in 1976. Now it consists 50% of underground continuous wall constructions in Japan, and widely adopted in countries in southeast Asia, the United States, France etc. In Shanghai, Hangzhou, Nanjing and other cities of China, SMW becomes quite popular after its introduction years ago. SMW uses multi-shaft auger to drill soil in situ, meanwhile pumps cement grout from the tips of the augers into the drilled holes. After sufficient mixing of the grout, H-shaped steel or other types of steel are embedded into the columns before the soil-cement mixture hardened, forming a underground continuous wall with rigidity and intensity. The wall could be used as retaining support or water seal. Three-shaft auger machine is commonly used. |

| SMW method has the following advantages: |

| 1.Low cost. Foundation retaining using SMW method with three-shaft auger machine is much more competitive in price than traditional method when constructing underground continuous wall. 2.Shorter construction period. SMW method consumes much less time than other methods. Under normal geographical conditions, it could build 70-80m² walls per shift. 3.Good seal quality. The wall is continuous without any cracks. Hydraulic conductivity can reach as much as 10-7cm/s. 4.No disturbance in nearby soils. SMW method would not cause hazards like ground subsidence, building inclining, road cracks or shift of underground facilities. 5.Wide range in use. It can be applied on cohesive soil, silt , sandy soil, gravel soil. 6.the waste soil is far less than other construction methods. |

| Name | Unit | Parameters |

|---|---|---|

| Hole dia. | mm | 600 |

| Center distance of rig | mm | 450 |

| Max drilling depth | m | 30 |

| Max output torque | kn·m | 84 |

| Rod rotary speed | r/min | 20 |

| Motor power | kw | 2X75 |

| Total weight | t | 19.8 |

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Multilayer, six layers! Real Estate Company real estate. I would like to ask you to build the foundation is a good pile or independent column good? May I have some questions from insiders?! Thank you

- Depends on geological reports, can not pile, it is best to save a lot of money Oh!

- Q: How many prestressed concrete pipe piles can a pile driver hit in a day?

- The degree of proficiency of your worker has something to do with geology. Normally, it's about 400 meters a day.

- Q: How to select the configuration of the pile driver, which parts are the key concerns?

- (5) diesel hammer pile machine, hoist hammer, hanging pile must use the winch ratchet insurance. Start piling hammer should be opened before the mechanical lock, the hammer claw retracts, starting out before starting the hook, prevent the hammer hanging from the pile top pile accident.(6) the diesel hammer hammer machine must adjust the amount of fuel supplied to control the height of the drop hammer, and must stop hammering when the second piston ring of the upper piston is seen.(7) diesel hammer pile machine, the end of the piling operation, the cylinder should be placed on the piston seat. The application of timber pile hammer pad or pin lock.(8) when the pile is driven by vibration, no one is allowed to stay in the lower part of the frame. When pulling out the vibration, it should be vertical upward and pull out at the same time.(9) the construction site of the static pile driver shall be flat and compacted, with a slope of no more than 3%, without any water accumulation, and no underground burial shall be confirmed.(10) power cable static pile pressing machine must overhead, electric box and motor ground zero protection line electric shock protector is firm and reliable, sensitive and effective action, not in high voltage wires under the pressure of pile, pile machine must be mobile and high-pressure line safety distance is not less than 6m.

- Q: I have a pile machine construction record card, but Supervision said or not, please master pointing.

- If there is any nonconformity, the rectification shall be completed and checked by the supervision.

- Q: What kind of industry can use a pile driver?

- Foundation piling machine, mainly used in the construction aspect of the piling machine and spiral wheel points, driving depth and diameter of pile are also different. Solar photovoltaic power station pile driver is widely used in desert and Gobi zone construction. The same Baoding also has developed a suitable electromechanical dual-purpose spiral piling machine, to meet the needs of different customer qualification and the environment.Hydraulic pile driver is a kind of multi-function highway guardrail steel pipe pile construction machinery. A new type of pile driver is adopted to adjust the hydraulic pressure according to the different stratum of the soil and drive the pile with proper impact force.

- Q: Why do some people need to dig the foundation and pile it up to dig a hole?

- how to do?You say the digging and then piling, probably because the pile is the need for technology, such as filling piles, you do not dig, you can not do, or that you have obstacles on the surface, to dig into the original soil piling, so good control piling quality

- Q: What is a loading type road pile driver?

- Loading type road pile driverThe utility model relates to a loading type road pile driver, which has the advantages of high efficiency and punching efficiency, is 1.5 times as much as that of a traditional pile driver, and has a special driving room. Ability to work at night and on rainy days. The power consumption is the same as that of a general pile driver. He looks very handsome, too.Turn left and turn right |From the picture we can see briefly that the loading type road pile driver is much better than the general road piling machine and looks better. The operating room is not as simple as this.

- Q: Does the pile driver belong to special equipment?

- Special equipment is the safety of life, the risk of large boilers, pressure vessels (including gas cylinders, the same below), pressure piping, elevator, crane, passenger ropeway, large recreation facilities and special motor vehicle factory. Piling machine does not belong to special equipment

- Q: How much is it to put a pile driver on the tractor?

- In fact, it is better to buy one directly on the tractor. We all have a cheap and good mechanical pile driver, and the quality is good. For details, please Baidu "Teng Teng machinery."".

- Q: Clean the dirt and grease piling machine how much money

- The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation.

Send your message to us

Drilling Rig for Construction of SMWBored Pile Drilling Rig

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords