Sheet Pile Driver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

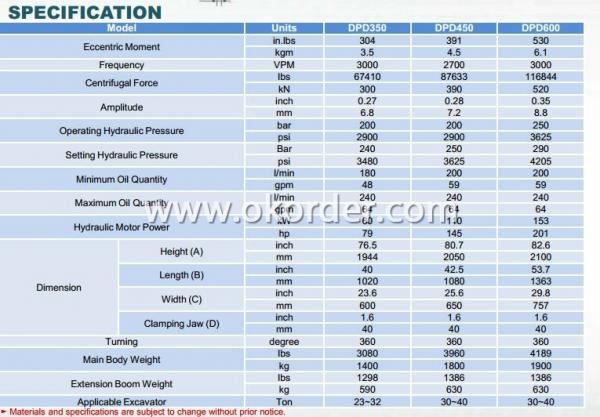

Detailed Product Description of Vibro Ripper, Hammer (Pile Driver)

- 360 degrees rotation of middle bracket

- Proven economic feasibility, mobility, safety

- Driving & Extraction sheet pile, tube, H-beam

- Most representative hydraulic vibro hammer

- Suitable equipment for construction working site

-Excellent performance and mechanisms without power pack.

-Proven workability: With the advantage of the excavator’s mobility, High performance operation at overpasses, under high voltage lines, on bridges and populated cities.

-Maximized the life of the equipment by using a special bearing designed for high frequency

-Best quality of Cushion elastomers are adopted in order to isolate vibration being transmitted to excavator.

-Easy installation using breaker hydraulic line of the excavator with electric cable device and operation control

-Mounting and dismounting can be easily done at all times

-The upper body allows 360 degree free rotation for easy operation and automatically anchors itself during operation

-Sheet pile, H beam and tube can be used by hooking up a wire on the main body of pile driver

-Double clamping devices can be fitted for pipe driving and extracting (Option)

- Q: Like bored pile machines and precast pile machines, they have no wheels, and they are very bulky. How do they move?Some people say that the demolition and then installed, a construction site three hundred or four hundred piles, it is difficult to dismantle three hundred or four hundred times?

- Walking pile machine, first with the 4 hydraulic cylinder (leg) to pile up the top, bottom rail pile machine to reach out, take back the leg pile machine down, and then pile machine by hydraulic cylinder thrust along the upper part of the track before reaching out to the track, work efficiency low. Our company is now producing crawler pile driver, mobile flexible, convenient location, electrical, hydraulic, centralized control, operation is very convenient.

- Q: My family is in the countryside, and now more than 100 meters behind the house in the pile is the kind of shock, our house is built in 99 years, has been very good. Since the piling, I have been shaking the door, the construction party every day for more than 8 hours, has been more than 10 days, and now I have a lot of cracks in the floor. What's the influence of our family, please? Are there any rules for investigating what should be done before piling?

- In engineering piling, because of the huge impact force, it can produce shock wave, which will cause some damage to the surrounding building.

- Q: Mechanical piling machine about how much money?

- Eight tons of assembly, probably one hundred and seventy thousand to one hundred and eighty thousand

- Q: A pile driver 1 team can play many 12mI36b steel sheet pile

- According to the geological conditions are different450 pile driverThe number of 9m Larson steel sheet piles is about 100 a day300 times the pile driverTrough sheet steel piles 9m in 200-300 days at a timeGive you a reference: 80 tonsThis is my construction data, I do not know, quasi accurate, you can refer to the next slightly!

- Q: Pile driver model, which brand is better?

- Small rotary drilling rig and small pile driver, the foundation pile foundation, compared to the screw pile driver, can meet all kinds of large-scale infrastructure construction requirements.As for the piling machine brand small piling machine is recommended a Matlock in Hunan, the drilling machine is widely used in city high-rise buildings, railways, highways, bridges, airports, ports and other pile foundation engineering irrigation pile construction, has wide application range, high construction efficiency, stable performance, and thoughtful service, environmental protection and energy saving the advantages of.

- Q: Handan steel sheet piling machine a number of how much money

- Trough steel sheet pile 9m 200-300Reference data: 80 tonsI know the construction data, quasi quasi reference

- Q: Several common pile foundations and pile driving techniques

- At the bottom of the drill bit, when rotating, the soil layer becomes loose and becomes slag. It is suspended by mud and overflowed with mud. The well wall is protected by water head and mud. Reverse circulation rotary drilling: the mud flows into the borehole from the mud pool and is mixed with drilling slag. Suction role in vacuum pump, drill into a slag mixture into the mouth, through the drill pipe, and a slurry pump debris control raft excreted into the sedimentation tank cleaning, for further use. Because the bore diameter of drill pipe is much smaller than that of well bore, the water slurry in drill pipe is increased by 4~5 times faster than that of positive circle, and it is dominant in drilling hole of bridge drilling pile.

- Q: Precast pile, artificial dig hole pile, sinking pipe filling pile, spiral drilling pouring pile and powder spraying pile.

- You need to use the term piling machine and every possible operation and maintenance costs have a general understanding, if each year period divided by total amount plus maintenance costs less than the lease, you can consider buying, similar or greater, or lease more appropriate.

- Q: Why should the pile foundation be excavated after the pile driving?

- If it is high-level, there are first excavation to the bottom of the foundation and then piling

- Q: The principle of pile driver

- (3) vibration hammer. Using the mechanical vibration force of the pile hammer to make the pile sink into the ground, it is suitable for carrying less precast concrete pile, steel sheet pile and so on.(4) static pile pressing machine. Produced by mechanical hoist or the pressure of the hydraulic system, the pile in the hydrostatic pressure under the action of pressure in the soil, various types of precast pile used in general bearing capacity.

1. Manufacturer Overview

| Location | South Korea |

| Year Established | 1982 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | Certificate of conformity with the following European Directives;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sheet Pile Driver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords