Grinding Glass Beads

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Kilograms kg

- Supply Capability:

- 500 Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

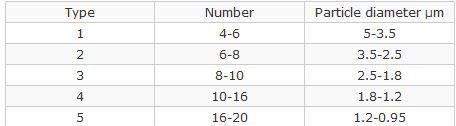

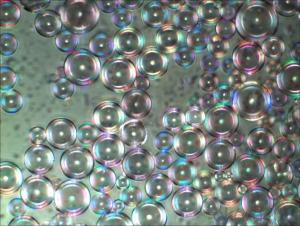

Grinding Glass Beads

strong hardness

new glasses for material

Round ratio above 85%

ISO, CE

Grinding Glass Beads

III. Hardness

HV, Loading 100g, residence time: 12s

the average of five point: 5270Mpa

standard

code(HV): ≥ 5000Mpa

IV. percentage of damage

1. test condition

(1)shot peening Target:Thickness:1.2mm (steel plate)

(2)air pressure of the nozzle:0.3Mpa

(3)the space between the nozzle and the Target: 200mm

(4) time of shot peening:5min

(5)the diameter of the glass beads: 250 microns

(6)Gross Weight of the tested glass beads: 1020g

(7) the weight of the damaged

glass beads after shot peening: 1.02g

2.percentage of damage of the test : 0.1%

V. Application

They are mainly used for the disperser, grinding media of industries, such as coloring, paint, ink, coatings, resins, chemical engineering, with the advantages of smooth surface, even size, high hardness, good chemical stability. Thanks to the characteristics of heat-resistant, wearable, compression strength, the filling-type bead could be used to improve glass fibre reinforced plastic, rubber, and so on.

- Q: If so, ask what it works forThe pile hammers I've seen before all have a steam hammer, and this one doesn't know how it works.

- Static pressure pile machine, the static pressure construction relies entirely on the hydraulic static pressure to push the pile into the ground. It's like nailing a nail into a wood, the jacked machine is pushing the nail in directly, and the other kind of diesel hammer can be seen as hammering in.

- Q: The distance is 400 meters. Is it possible to use 120 of the aluminum core cable? If not, how much cable should be used? Empty 20How big the cable 250KW piling machine, the distance is 400 meters, can use the aluminum core cable 120, if not, the cable for much, much of the air distribution.

- This is the minimum limit. The air switch shall be 630 safe. With a soft starter box, if the star triangle is activated, two 240 square cables can be used to connect the six terminals of the motor and the starter box.

- Q: Invite friends together to buy a long spiral step of 30 meters of the pile driver, told me as long as the project profits are objective, you can package to 200W/, would like to ask the experts familiar with the bank bosses according to your local market if the annual package is how much money, how much is the monthly package, or by how many meters.. Thank you。。 Thank you

- The drilling system comprises a power head and the output shaft of the power drill head and screw drill is hollow, with long spiral hole, drill pipe through the center of the concrete [or] of the mud pumping concrete CFG pile construction, which can be a drilling machine once completed, can also be used to dry hole, grouting altering tool can also be taken deep mixing a variety of Engineering construction.

- Q: I have learned how to drive a pile driver. I want to know what the salary is. How can I find a job in the future?

- I drive a pile driver. What kind of pile driver do you learn?

- Q: What is the power of the pile driver?

- The power of the pile driver is between 50-150W, and the power of the different types of pile drivers is different.Pile driver is composed of pile hammer, pile support and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..

- Q: Does the mud come up with the shovel? Can you tamper with a stone? 1.2 traction? How many meters per hour can the ramming mud fall? And the price of the equipment! It's better to have a talk with that big brother! Thank you on your knees

- 80 generally refers to the 456080 common hammer and so on is 60 of the hammer that I is the 60 80 hammer is not a lot of major areas this is not to say the price is equipped with 80 hammer down the price is a full set of 45W-50W including the hammer cable wire rope mechanical appearance does not include cable wire rope.

- Q: How many tons of pile drivers are used to hit 400X400 square piles?

- Usually with 6.3 ton or 8.3 tons of guide rod, diesel hammer will be able to hit. The static pile machine is not clear.

- Q: What is a loading type road pile driver?

- The emergence of the loader pile driver is a breakthrough in the piling machine industry. It not only improves the efficiency of drilling, but also has the ability to work at night as well as the ability to prevent rain and water. It has longer life, better quality and, of course, more expensive prices. But in general, it's good value for money.Traditional road pile driverThe traditional highway pile driver doesn't have the working conditions at night and rainy day, but the punching efficiency is high, but it is not as good as that of the loading type road pile driver. It looks shabby.

- Q: What is the noise of a static pile and a diesel pile driver?

- The noise of the static pile is small, so it is suitable for the construction in the city and the construction cost is higher.The diesel pile driver has large noise and is suitable for field construction, and the construction cost is low.

- Q: What is the maximum CPU of a pile driver? What about the performance of graphics will be piling machine CPU?

- The official use of Bulldozer as the core code shows the unmatched performance of the CPU series.The bulldozer is the United States AMD company to re design of the CPU architecture, officially launched in October 2011, have a fever for high-end user, with DDR3-1866MHz native memory support, XOP instruction set, the modular design and a number of new features, fully replace the phenom processor of II series.

1. Manufacturer Overview

| Location | Liaoning, China (Mainland) |

| Year Established | 2000 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications | ISO:9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Grinding Glass Beads

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Kilograms kg

- Supply Capability:

- 500 Tons per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords