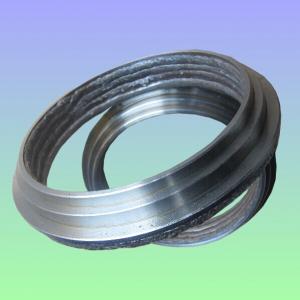

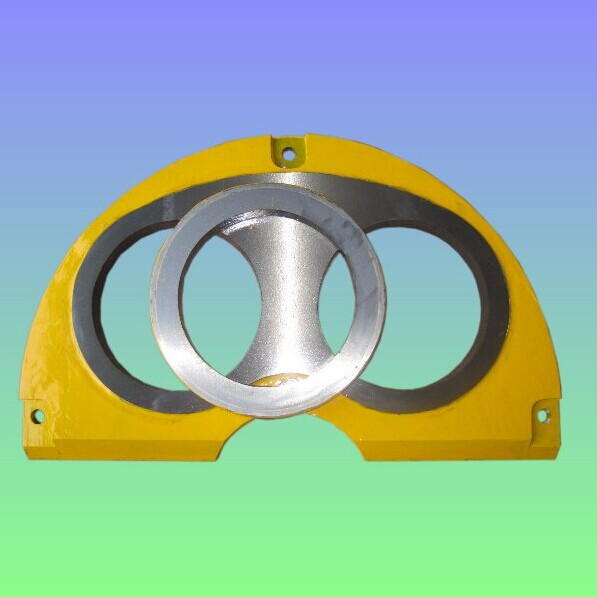

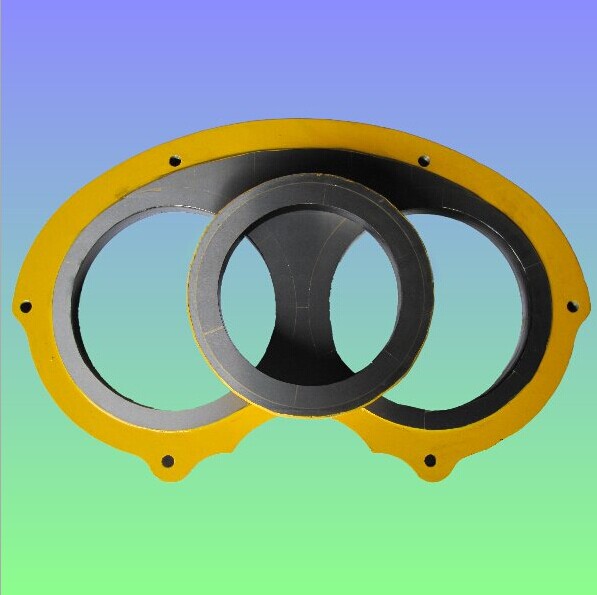

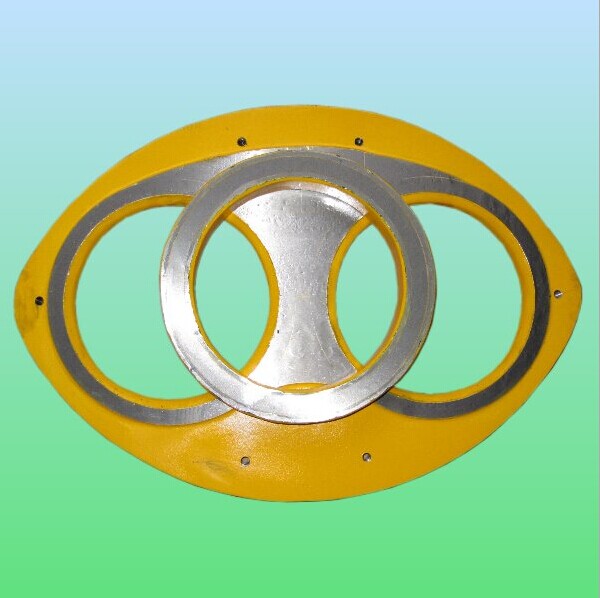

Zoomlion Spectacle Wear Plate and Cutting Ring DN200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name:Zoomlion Spectacle Wear Plate and Cutting Ring DN200

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade.

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 25000 N/mm2

6. Application: trailer and trunk mounted Zoomlion concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our Zoomlion Spectacle Wear Plate and Cutting Ring DN200 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs Zoomlion Spectacle Wear Plate and Cutting Ring DN200 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Zoomlion Spectacle Wear Plate and Cutting Ring DN200 according to customers request?

A4: Yes, we can produce Zoomlion Spectacle Wear Plate and Cutting Ring DN200 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What are the different types of concrete pump hopper pins?

- There are several types of concrete pump hopper pins, including snap pins, lynch pins, and clevis pins. These pins are used to secure the hopper to the pump and ensure it stays in place during operation.

- Q: What are the signs of a malfunctioning hydraulic oil cooler?

- Some signs of a malfunctioning hydraulic oil cooler include overheating of the hydraulic system, decreased performance and efficiency of the equipment, increased hydraulic fluid leakage, abnormal noises or vibrations, and visible signs of coolant or oil leakage around the oil cooler.

- Q: How can one ensure proper functioning of concrete pump spare parts after installation?

- To ensure the proper functioning of concrete pump spare parts after installation, there are a few key steps that can be followed: 1. Quality Assurance: It is crucial to purchase spare parts from reputable manufacturers or suppliers. Ensure that the spare parts are of high quality, made from durable materials, and comply with industry standards. This will significantly reduce the risk of malfunctioning parts. 2. Proper Installation: It is essential to follow the manufacturer's guidelines and recommendations for the installation of concrete pump spare parts. Each component should be installed correctly, with the right torque and alignment. It is advisable to seek professional assistance if needed to ensure proper installation. 3. Regular Maintenance: Regular maintenance is crucial for the proper functioning of concrete pump spare parts. Create a maintenance schedule and follow it diligently. This includes inspecting and cleaning the spare parts, checking for any signs of wear or damage, and lubricating moving parts as required. 4. Timely Replacement: Over time, concrete pump spare parts may wear out or become damaged due to continuous use. It is essential to monitor the condition of the spare parts and replace them when necessary. Regularly inspecting the parts and promptly replacing any worn-out or damaged components will help maintain the proper functioning of the pump. 5. Training and Education: Ensuring that the operators and maintenance personnel are properly trained and educated is crucial for the proper functioning of concrete pump spare parts. They should be familiar with the equipment, its spare parts, and the correct procedures for installation and maintenance. Regular training sessions can help improve their knowledge and skills, resulting in better maintenance and performance of the spare parts. By following these steps, one can ensure the proper functioning of concrete pump spare parts after installation, enhancing the overall efficiency and longevity of the equipment.

- Q: What is the purpose of a concrete pump electric motor?

- The purpose of a concrete pump electric motor is to provide the necessary power and torque to pump concrete from one location to another, eliminating the need for manual labor and increasing efficiency in construction projects.

- Q: What are the indications of a malfunctioning concrete pump water pump?

- A malfunctioning concrete pump water pump can be identified through several indicators. 1. Insufficient water flow: A clear sign of a faulty water pump is the lack of water flow. If the pump is not operating correctly, it may fail to supply water to the concrete pump, leading to reduced or no water flow. 2. Decreased water pressure: Another indication of a malfunctioning water pump is reduced water pressure. If the pump is not working properly, it may struggle to generate sufficient pressure for effective water delivery to the concrete pump. This can result in a weaker or inconsistent stream of water. 3. Abnormal noises or vibrations: Strange noises or vibrations emitted by the water pump can suggest a malfunction. Mechanical issues or loose components within the pump can cause these unusual sounds or vibrations. 4. Excessive heat: A malfunctioning water pump can also overheat due to various reasons such as a clogged filter, worn-out bearings, or a faulty motor. Overheating can cause further damage and eventually lead to the pump's complete failure. 5. Leakage: The presence of visible leaks around the water pump indicates a malfunction. Damaged seals or gaskets, loose connections, or cracks in the pump housing can cause leaks. These leaks result in water loss and reduced pump efficiency. 6. Inconsistent or unpredictable water flow: When the water pump is not functioning properly, it can cause irregular or unpredictable water flow. This uneven distribution of water to the concrete pump affects the quality and consistency of the pumped concrete. Regular inspection and maintenance of the water pump are crucial to ensure its proper functioning. If any of these signs are observed, it is advisable to promptly address the issue by seeking professional assistance to diagnose and repair the malfunctioning water pump.

- Q: Are there any specific guidelines for the disposal of packaging materials of concrete pump spare parts?

- Packaging materials of concrete pump spare parts have specific guidelines for disposal. It is advised to adhere to local waste management regulations and authorities' guidelines. To begin with, it is essential to separate the various packaging materials, such as cardboard boxes, plastic wraps, foam inserts, and other materials used for packaging the spare parts. This will facilitate efficient recycling or appropriate disposal of each material. Cardboard boxes can usually be recycled by flattening them and placing them in designated recycling bins. Plastic wraps should also be separated and discarded in specific plastic recycling bins. Foam inserts, commonly used for spare parts protection, may not be recyclable in all areas, so specific recycling instructions should be checked. If recycling is not possible, foam inserts can be disposed of in regular waste bins. Before disposal, it is important to ensure that all packaging materials are free from any residual concrete or other hazardous substances. Any contamination should be cleaned or removed properly to prevent environmental pollution. If the packaging materials cannot be recycled or disposed of through regular waste management methods, it is recommended to contact local recycling centers or waste management facilities to inquire about specific disposal options. They may offer guidance or accept these materials for specialized processing or disposal. Overall, responsible waste management practices should be prioritized, and compliance with local authorities' specific guidelines is crucial to ensure proper disposal of packaging materials for concrete pump spare parts.

- Q: Are there any specific guidelines for the installation of control valves or solenoids in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control valves or solenoids in concrete pump spare parts. These guidelines typically include proper alignment, mounting, and connection procedures to ensure optimal performance and longevity of the components. Additionally, it is important to follow manufacturer's instructions and recommendations for the specific model of control valve or solenoid being installed.

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- To ensure optimal functionality, it is necessary to regularly inspect the antennas of the concrete pump remote control. The frequency of these inspections will vary depending on the usage and working conditions of the pump. In general, it is advisable to conduct inspections at least once a year or after every 500 hours of usage, whichever occurs first. However, if the pump is subjected to harsh environments or experiences frequent wear and tear, more frequent inspections may be required. It is crucial to carefully examine the antennas for any indications of damage, such as cracks, corrosion, or loose connections. If any damage is detected, immediate replacement of the antenna is essential to prevent disruptions in the remote control signal. By conducting regular inspections and promptly replacing antennas when necessary, the concrete pump can operate smoothly and efficiently.

- Q: Can I repair concrete pump spare parts instead of replacing them?

- Yes, it is possible to repair concrete pump spare parts instead of replacing them in some cases. Many concrete pump spare parts can be repaired, such as seals, gaskets, valves, and hydraulic components. However, the feasibility of repair depends on the extent of the damage and the specific part in question. Some damaged parts may be too worn or damaged to be effectively repaired, and in those cases, replacement may be necessary. It is important to consult with a professional or contact the manufacturer to determine if repair is a viable option for your specific concrete pump spare parts.

- Q: What are some common issues with concrete pump pipes and how can they be prevented?

- Concrete pump pipes can experience several common issues, including blockages, leaks, and wear and tear. These problems can be avoided by implementing appropriate maintenance and operational practices. 1. Blockages: Concrete hardening inside the pipe can obstruct the flow, resulting in blockages. Regularly cleaning the pipes after each use is crucial to prevent blockages. Flushing the pipes with water or using a high-pressure air hose can eliminate any remaining material and prevent buildup. Furthermore, using concrete mixtures with the correct consistency and avoiding excessive use of additives can minimize the chances of blockages. 2. Leaks: Cracks or gaps in the pipe can cause concrete to leak out. Regularly inspecting the pipes is vital to detect any signs of damage or wear. Promptly repairing or replacing damaged sections can prevent leaks. It is also essential to use high-quality pipes that resist abrasion and chemical corrosion as they are less likely to develop leaks. 3. Wear and Tear: The operation of concrete pump pipes exposes them to significant stress and abrasion. This can eventually lead to wear and tear, resulting in weakened pipes or even breakages. To prevent excessive wear, it is important to utilize pipes made from durable materials like hardened steel or composite materials. Regularly inspecting the pipes for signs of wear, such as thinning or deformation, and replacing them as needed can help prevent sudden failures. 4. Pipe movement and alignment issues: During operation, concrete pump pipes may shift or become misaligned, which can decrease efficiency and potentially cause damage. To prevent this, ensure that the pipes are securely fastened to the pump and properly aligned. Using clamps and brackets or employing anti-vibration measures can help maintain the stability and alignment of the pipes during pumping operations. 5. Operator errors: Improper handling and operation can also contribute to problems with concrete pump pipes. Operators should receive adequate training in pump operation and pipe handling. Following recommended operating procedures, avoiding excessive pressure or flow rates, and exercising caution while maneuvering the pipes can prevent unnecessary strain and damage. In conclusion, proactive maintenance, proper handling, and the use of high-quality pipes can greatly reduce common issues with concrete pump pipes, ensuring smooth and efficient concrete pumping operations.

Send your message to us

Zoomlion Spectacle Wear Plate and Cutting Ring DN200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords