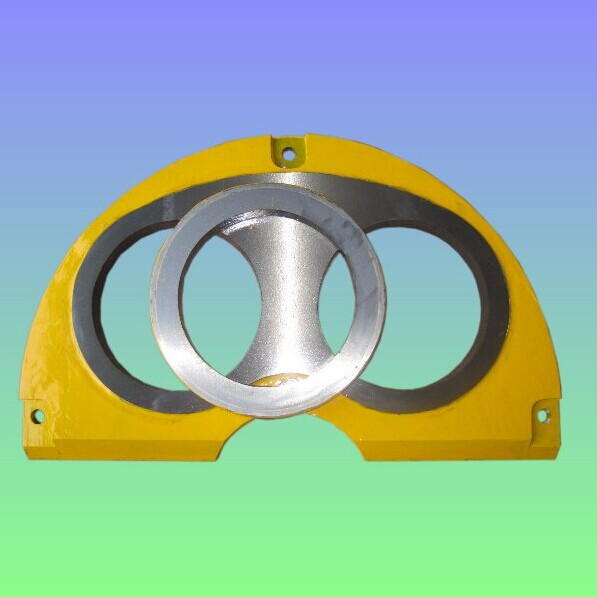

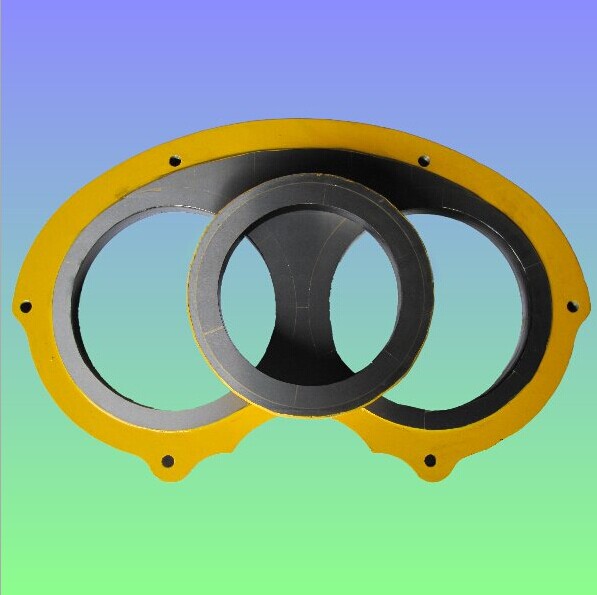

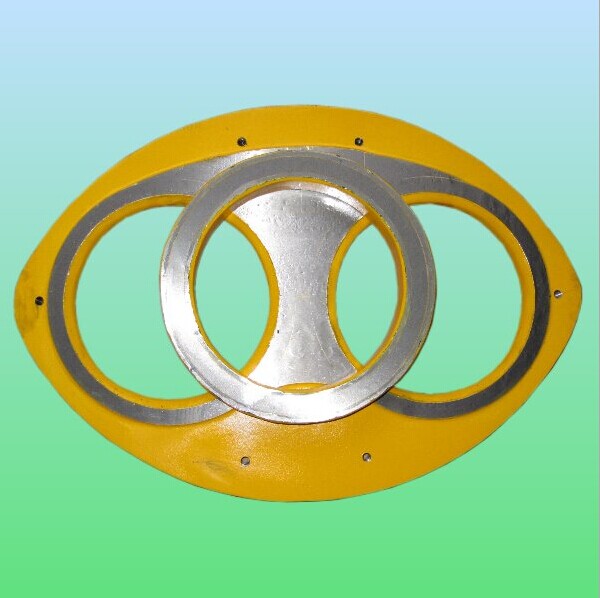

SANY DN200 Spectacle Wear Plate and Cutting Ring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: SANY DN200 Spectacle Wear Plate and Cutting Ring

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Sany concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our Concrete Pump Spectacle Wear Plate and Cutting Ring have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs SANY DN200 Spectacle Wear Plate and Cutting Ring put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump Spectacle Wear Plate and Cutting Ring according to customers request?

A4: Yes, we can produce Concrete Pump Spectacle Wear Plate and Cutting Ring according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: How often should concrete pump outriggers be inspected and maintained?

- Concrete pump outriggers should be inspected and maintained regularly to ensure their safe and efficient operation. It is recommended to inspect and maintain concrete pump outriggers before each use and at least once every six months. However, the frequency of inspections may vary depending on the specific conditions and intensity of use. Regular inspections should include checking the condition of the outrigger pads, hydraulic cylinders, and other components for any signs of wear, damage, or leaks. Any necessary repairs or replacements should be carried out promptly to prevent further damage and ensure the outriggers are in proper working condition. Additionally, proper lubrication of moving parts and regular cleaning of the outriggers can help prolong their lifespan and maintain their performance.

- Q: How often should hopper screens be cleaned or replaced?

- Hopper screens should be cleaned or replaced regularly, ideally on a quarterly basis, to ensure proper functioning and prevent clogging or damage to the equipment.

- Q: What is the difference between concrete pump and ground pump?

- The pump is actually the day Linuo arm frame of concrete pump boom is known, a few day, after mixing through the boom pump, the efficiency is very high

- Q: What are the signs of a malfunctioning lubrication system?

- There are several signs that can indicate a malfunctioning lubrication system. Firstly, if you notice any unusual noises coming from the engine, such as grinding or squealing, it could be a sign that the lubrication system is not properly lubricating the moving parts. Additionally, if you start to experience a decrease in engine performance or a loss of power, it could be due to insufficient lubrication. Another common sign is the presence of oil leaks, which can indicate a problem with the lubrication system seals or gaskets. If you notice a burning smell or smoke coming from the engine, it could be a sign of oil leaking onto hot engine components. Finally, monitoring the oil pressure gauge is essential, as a malfunctioning lubrication system can result in low oil pressure, which can lead to engine damage if not addressed promptly. Overall, it is important to pay attention to these signs and address any potential issues with the lubrication system to ensure the proper functioning and longevity of your engine.

- Q: How do I properly maintain and replace filters in concrete pump spare parts?

- Properly maintaining and replacing filters in concrete pump spare parts is essential for ensuring optimal performance and longevity of your equipment. Here are some steps to follow: 1. Understand the different types of filters: Concrete pumps typically have different filters for various components, such as hydraulic oil, fuel, air, and water. Familiarize yourself with the specific filters used in your equipment. 2. Refer to the manufacturer's guidelines: Read the equipment manual and follow the guidelines provided by the manufacturer regarding filter maintenance and replacement intervals. This will help ensure that you are following the recommended practices. 3. Regularly inspect filters: Periodically inspect the filters to identify any signs of damage, clogging, or excessive debris accumulation. This can be done visually or by checking the pressure differential across the filter. If the pressure differential exceeds the recommended limit, it may indicate a need for filter replacement. 4. Clean or replace filters as needed: If the filters are clogged or dirty, they need to be cleaned or replaced. Some filters can be cleaned by blowing compressed air in the opposite direction of the airflow to remove debris. However, it is important to note that some filters are disposable and cannot be cleaned. 5. Use genuine spare parts: When replacing filters, always use genuine spare parts recommended by the manufacturer. This ensures compatibility and performance. 6. Follow proper handling and installation procedures: When installing new filters, make sure to handle them with clean hands or gloves to prevent contamination. Follow the correct installation procedure, such as tightening the filter housing to the recommended torque value. 7. Keep a maintenance schedule: Establish a regular maintenance schedule for filter inspection, cleaning, and replacement. This will help you stay on top of filter maintenance and prevent any potential issues caused by dirty or clogged filters. By following these steps, you can properly maintain and replace filters in concrete pump spare parts, ensuring that your equipment operates efficiently and has an extended lifespan.

- Q: How often should concrete pump seals be replaced?

- Concrete pump seals should be replaced every 500 to 800 hours of operation or whenever signs of wear, leakage, or decreased performance are observed.

- Q: How do I properly maintain and replace hydraulic motors in concrete pump spare parts?

- To ensure smooth operation and long-lasting performance of concrete pump spare parts, it is crucial to properly maintain and replace hydraulic motors. Here are some effective steps to guide you: 1. Regularly inspect the hydraulic motors to detect any signs of wear, damage, or leaks. Ensure the fluid levels are at the recommended levels. 2. Keep the hydraulic motors clean by removing dirt, debris, and contaminants. This prevents overheating and minimizes the risk of internal component damage. 3. Follow the manufacturer's recommendations and regularly check and change the hydraulic fluid. Clean and replace filters to prevent damage-causing particles. 4. Lubricate the hydraulic motors according to the manufacturer's instructions. This reduces friction and wear on moving parts, improving overall performance and lifespan. 5. Operate the concrete pump within the recommended load and pressure limits specified by the manufacturer. Excessive pressure or overloading can stress the hydraulic motors, leading to premature failure. 6. Keep track of the service life and usage of hydraulic motors. Over time, they may become less efficient. Promptly replace them to avoid disruptions to concrete pumping operations. 7. If unsure about maintenance or replacement, seek professional assistance. Professionals have the expertise to carry out tasks correctly, ensuring safety and optimal performance of concrete pump spare parts. By following these steps, you can effectively maintain and replace hydraulic motors in concrete pump spare parts, ensuring equipment longevity and efficiency.

- Q: Can I use alternative materials for concrete pump spare parts?

- Yes, it is possible to use alternative materials for concrete pump spare parts. However, it is important to consider the specific requirements and performance characteristics of the parts before making any substitutions. Concrete pump spare parts are designed to withstand high pressures and abrasive materials, so using alternative materials that can withstand these conditions is crucial. It is recommended to consult with the manufacturer or a professional in the field to ensure that the alternative materials chosen will not compromise the performance or safety of the concrete pump.

- Q: If the concrete pump valve jam how to judge and deal with?

- After pumping concrete, be sure to use high-pressure water to pump the body and S pipe clean. When the rinse is not available, tap the tap to remove the residue until it is thoroughly clean.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 6 to 12 months, to ensure their proper functioning. Replacement of hydraulic cylinders should be done only when necessary, such as in cases of significant wear and tear, severe damage, or if they fail to meet safety standards.

Send your message to us

SANY DN200 Spectacle Wear Plate and Cutting Ring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords