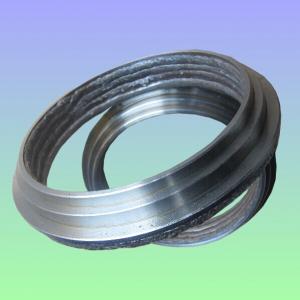

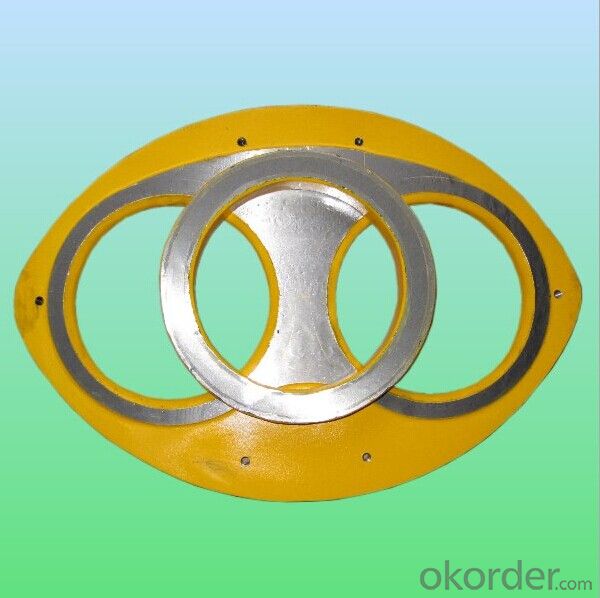

Putzmeister Spectacle Wear Plate and cutting Ring DN200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Putzmeister Spectacle Wear Plate and cutting Ring DN200

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Putzmeister concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our Putzmeister Spectacle Wear Plate and cutting Ring DN200 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

3. Package

Every 60pcs Tungsten Carbide Putzmeister Spectacle Wear Plate and cutting Ring DN200 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Tungsten Carbide Putzmeister Spectacle Wear Plate and cutting Ring DN200 according to customers request?

A4: Yes, we can produce Putzmeister Spectacle Wear Plate and cutting Ring DN200 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: Can concrete pump spare parts be resold or traded in for new parts?

- It is possible to resell or trade in concrete pump spare parts for new ones. The viability of reselling them depends on the condition and demand for the parts. There are different platforms, both online and offline, where individuals or businesses can sell their used spare parts. Moreover, some manufacturers or distributors may have trade-in programs that allow customers to exchange old parts for new ones, offering a cost-effective way to upgrade their equipment. However, the resale value or trade-in options may differ based on factors like the age, condition, and market demand for the specific parts.

- Q: How often should concrete pump gearboxes be inspected and maintained?

- Concrete pump gearboxes should be inspected and maintained at regular intervals, typically every 6 to 12 months. However, the frequency may vary depending on the specific operating conditions and usage of the concrete pump. It is important to follow the manufacturer's recommendations and guidelines for maintenance to ensure optimal performance and longevity of the gearboxes.

- Q: What is the function of a concrete pump control lever?

- The function of a concrete pump control lever is to control the flow and direction of the concrete being pumped. It allows the operator to start and stop the pump, adjust the speed of the pump, and control the placement and placement speed of the concrete. The control lever also enables the operator to switch between different pumping modes, such as pumping vertically or horizontally, and adjust the pressure of the concrete being pumped. Overall, the control lever is essential in ensuring accurate and efficient concrete pumping operations.

- Q: What are the indications of a faulty concrete pump hydraulic motor?

- Some indications of a faulty concrete pump hydraulic motor may include decreased pumping efficiency, irregular or inconsistent flow of concrete, unusual noises or vibrations, leaks or drips in the hydraulic system, excessive heat in the motor, or difficulty in starting or stopping the motor.

- Q: How do I properly maintain and replace hydraulic motors in concrete pump spare parts?

- To ensure smooth operation and long-lasting performance of concrete pump spare parts, it is crucial to properly maintain and replace hydraulic motors. Here are some effective steps to guide you: 1. Regularly inspect the hydraulic motors to detect any signs of wear, damage, or leaks. Ensure the fluid levels are at the recommended levels. 2. Keep the hydraulic motors clean by removing dirt, debris, and contaminants. This prevents overheating and minimizes the risk of internal component damage. 3. Follow the manufacturer's recommendations and regularly check and change the hydraulic fluid. Clean and replace filters to prevent damage-causing particles. 4. Lubricate the hydraulic motors according to the manufacturer's instructions. This reduces friction and wear on moving parts, improving overall performance and lifespan. 5. Operate the concrete pump within the recommended load and pressure limits specified by the manufacturer. Excessive pressure or overloading can stress the hydraulic motors, leading to premature failure. 6. Keep track of the service life and usage of hydraulic motors. Over time, they may become less efficient. Promptly replace them to avoid disruptions to concrete pumping operations. 7. If unsure about maintenance or replacement, seek professional assistance. Professionals have the expertise to carry out tasks correctly, ensuring safety and optimal performance of concrete pump spare parts. By following these steps, you can effectively maintain and replace hydraulic motors in concrete pump spare parts, ensuring equipment longevity and efficiency.

- Q: Are there any specific guidelines for the installation of control panels or electronic components in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control panels or electronic components in concrete pump spare parts. These guidelines typically recommend ensuring proper grounding, protection from moisture and vibration, and compliance with electrical codes and safety standards. It is crucial to follow these guidelines to ensure the efficient and safe operation of the equipment.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 500 hours of operation or at least once a year, whichever comes first. However, it is important to note that the frequency of inspections may vary depending on the specific conditions and usage of the concrete pump. During inspections, qualified technicians should thoroughly examine the hydraulic cylinders for any signs of wear, damage, or leaks. They should also check the alignment, piston rods, seals, and other components to ensure proper functioning. If any issues are found, such as excessive wear or leaks, it is recommended to replace the hydraulic cylinders promptly to prevent further damage and maintain optimal performance. Regular inspections and timely replacements of hydraulic cylinders are crucial for ensuring the safety, efficiency, and longevity of a concrete pump. Neglecting proper maintenance can lead to costly repairs, decreased productivity, and even accidents. Therefore, it is essential to follow manufacturer's guidelines and consult with professionals to determine the appropriate inspection and replacement intervals for hydraulic cylinders in a concrete pump.

- Q: Are there any specific quality control measures for the production of concrete pump spare parts?

- Concrete pump spare parts are subject to specific quality control measures to guarantee that they meet the necessary specifications and are of excellent quality. Standardized production processes are one of the primary quality control measures employed. Manufacturers adhere to particular procedures and guidelines during the production of spare parts, ensuring consistency and accuracy. This involves using high-quality materials, precise measurements, and advanced manufacturing techniques. To further ensure quality, rigorous testing and inspection take place throughout the production process. Dimensional checks, hardness tests, and material composition analysis, among others, are conducted to identify any defects or deviations from the required standards. Prompt corrective actions can then be taken. To continuously improve production processes, manufacturers may implement quality management systems like ISO 9001. These systems establish quality objectives, monitor performance, and implement corrective actions when needed. Furthermore, manufacturers may seek third-party quality assessment and certification. Independent organizations conduct audits and inspections to ensure that the spare parts meet the required quality standards. Certifications from these programs provide customers with assurance regarding the quality and reliability of the spare parts. In conclusion, the production of concrete pump spare parts undergoes strict quality control measures to meet necessary specifications and ensure high quality. These measures contribute to the performance, durability, and reliability of the spare parts in concrete pump applications.

- Q: Can a concrete pump pipe be repaired or should it be replaced?

- A concrete pump pipe can typically be repaired rather than replaced, depending on the extent of the damage.

- Q: What are the key considerations when purchasing spare parts for a concrete pump?

- When buying spare parts for a concrete pump, there are several important factors to think about. These factors include making sure that the spare parts are compatible with the concrete pump's make and model, checking their quality and reliability, ensuring their availability, and considering their cost-effectiveness. First and foremost, it is crucial to make sure that the spare parts you purchase are suitable for the concrete pump you have. Concrete pumps come in different makes and models, and each may have specific requirements for spare parts. Therefore, it is essential to carefully match the specifications and requirements of the concrete pump with the spare parts you buy to ensure proper functionality and performance. The quality and reliability of the spare parts are also important considerations. Investing in high-quality spare parts can have a significant impact on the efficiency and lifespan of the concrete pump. It is advisable to choose spare parts from reputable manufacturers or suppliers who have a proven track record of producing reliable products. Doing thorough research and reading customer reviews can help assess the quality and reliability of the spare parts. Availability is another crucial factor to consider when purchasing spare parts for a concrete pump. It is important to ensure that the spare parts you need are easily accessible, either from local suppliers or through efficient delivery channels. Delays in obtaining the necessary spare parts can result in extended downtime and increased costs. Therefore, it is recommended to choose suppliers with a reliable and efficient distribution network. Cost-effectiveness is also a key consideration when buying spare parts. While it is important to prioritize quality and reliability, it is equally important to find spare parts that offer good value for money. Comparing prices from different suppliers and considering the lifespan and potential maintenance costs of the spare parts can help make a cost-effective decision. It is crucial to strike a balance between cost and quality to ensure the best return on investment. In conclusion, when purchasing spare parts for a concrete pump, it is important to consider compatibility, quality, availability, and cost-effectiveness. By carefully evaluating these key factors, you can ensure that the spare parts you choose will meet the specific needs of your concrete pump, maintain its performance and reliability, and provide value for your money.

Send your message to us

Putzmeister Spectacle Wear Plate and cutting Ring DN200

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords