Tungsten Carbide PM200 Spectacle Wear Plate and Cutting Ring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

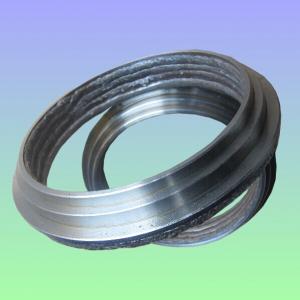

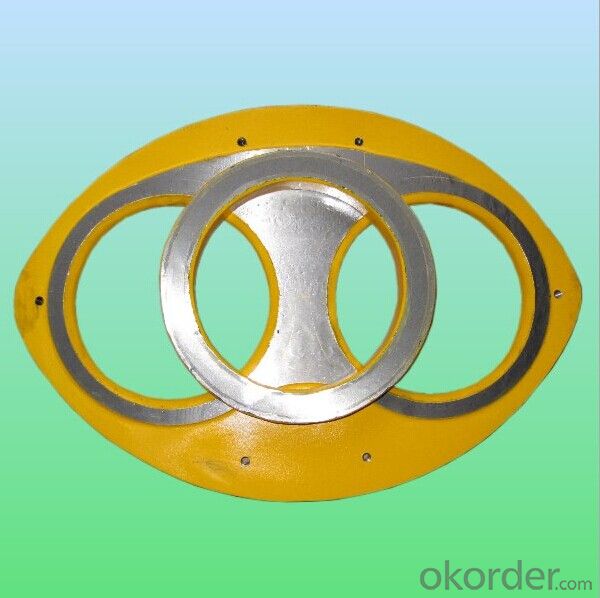

Product Name: Tungsten Carbide PM200 Spectacle Wear Plate and Cutting Ring

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Putzmeister concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Trailer and track mounted Putzmeister concrete pump. Our Concrete Pump Spectacle Wear Plate and Cutting Ring have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs Concrete Pump Bend DN125 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump Spectacle Wear Plate and Cutting Ring according to customers request?

A4: Yes, we can produce Concrete Pump Spectacle Wear Plate and Cutting Ring according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | |

- Q: What is the purpose of a concrete pump agitator motor?

- The objective of a concrete pump agitator motor is to guarantee the uniformity and excellence of the concrete mixture being transported. Its role involves ensuring that the concrete mixture remains well-blended and prevents any settling or separation during the pumping procedure. The agitator motor aids in maintaining a consistent and homogeneous mixture, which is essential for achieving sturdy and long-lasting concrete structures. Through continuous agitation of the concrete inside the pump, the motor assists in averting any obstruction or congestion that may potentially disrupt the pumping operation. In general, the purpose of a concrete pump agitator motor is to optimize the efficiency and effectiveness of the concrete pumping process, ultimately leading to improved construction outcomes.

- Q: What are the advantages of using carbon fiber components in concrete pump spare parts?

- There are several advantages of using carbon fiber components in concrete pump spare parts. Firstly, carbon fiber is known for its high strength-to-weight ratio. This means that carbon fiber components can provide the same strength as traditional materials such as steel or aluminum but with significantly less weight. This results in lighter spare parts, making them easier to handle and install, and also reducing the overall weight of the concrete pump system. Secondly, carbon fiber is highly resistant to corrosion. Unlike steel, carbon fiber does not rust or corrode when exposed to moisture or chemicals. This makes carbon fiber components ideal for use in concrete pump spare parts, as they are constantly exposed to water, cement, and other corrosive substances. The corrosion resistance of carbon fiber ensures the longevity and durability of the spare parts, reducing the need for frequent replacements and maintenance. Another advantage of carbon fiber components is their high stiffness. Carbon fiber is known for its rigidity and low flexural deformation, which means that the spare parts made from carbon fiber will have minimal deflection under load. This stiffness helps to maintain the overall stability and performance of the concrete pump system, ensuring accurate and efficient pumping of concrete. Additionally, carbon fiber has excellent fatigue resistance. Concrete pump spare parts are subjected to continuous cyclic loading and unloading, which can lead to fatigue failure over time. However, carbon fiber components have the ability to withstand these cyclic loads without compromising their structural integrity. This improves the reliability and lifespan of the spare parts, reducing downtime and maintenance costs. Lastly, carbon fiber offers design flexibility. It can be easily molded into complex shapes and geometries, allowing for customized spare parts that can be tailored to specific requirements. This flexibility in design enables the optimization of the spare parts' performance, enhancing the overall efficiency and productivity of the concrete pump system. In conclusion, the advantages of using carbon fiber components in concrete pump spare parts include their high strength-to-weight ratio, corrosion resistance, stiffness, fatigue resistance, and design flexibility. These qualities contribute to the improved performance, durability, and cost-effectiveness of the concrete pump system.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: How do I find the right part number for a specific concrete pump spare part?

- To find the right part number for a specific concrete pump spare part, there are a few steps you can follow: 1. Identify the specific part you need: First, determine the exact part you are looking for. This could be a specific component or a replacement part for a particular area of the concrete pump. 2. Consult the equipment manual: Check the equipment manual or documentation that came with the concrete pump. The manual often includes a parts list or diagram, which can help you identify the part number you need. 3. Contact the manufacturer or supplier: Reach out to the manufacturer or supplier of the concrete pump to inquire about the specific part you require. Provide them with the make, model, and serial number of the pump, as well as a detailed description or photograph of the part if possible. They should be able to provide you with the correct part number and any additional information you may need. 4. Use online resources: Utilize online resources such as manufacturer websites, spare parts catalogs, or specialized equipment platforms. These platforms often have search functions where you can input the make and model of the concrete pump to find the corresponding part numbers. 5. Seek assistance from industry experts: If you are still unable to find the right part number, consider reaching out to industry experts or professionals who specialize in concrete pump equipment. They may have the knowledge and experience to help you identify the correct part number based on your specific needs. Remember to double-check the part number provided by the manufacturer or supplier to ensure accuracy before making any purchases. Additionally, it is advisable to keep a record of the part number for future reference in case you need to reorder or replace the part again.

- Q: How often should concrete pump gearboxes be inspected and maintained?

- Concrete pump gearboxes should be inspected and maintained at regular intervals, typically every 6 to 12 months. However, the frequency may vary depending on the specific operating conditions and usage of the concrete pump. It is important to follow the manufacturer's recommendations and guidelines for maintenance to ensure optimal performance and longevity of the gearboxes.

- Q: How often should a hopper filter be cleaned or replaced?

- A hopper filter should ideally be cleaned or replaced every 3 to 6 months, depending on the usage and the level of contamination.

- Q: How does a concrete pump piston work?

- A concrete pump piston works by using hydraulic pressure to push the concrete mixture from the hopper into the delivery pipeline. The piston moves back and forth inside a cylinder, creating suction on one side and pressure on the other. As the piston retracts, it creates a vacuum that draws the concrete mixture into the cylinder. On the forward stroke, the piston compresses the concrete, forcing it out through the discharge valve and into the delivery pipeline, allowing for efficient and continuous concrete pumping.

- Q: What is the function of a concrete pump water pump?

- The function of a concrete pump water pump is to supply water to the concrete pump system for various purposes. It is responsible for providing a continuous flow of water to the concrete pump, which helps in the mixing and pumping of concrete efficiently. The water pump ensures that the concrete mix remains at the desired consistency by adding water as needed during the pumping process. It helps to control the hydration process of the cement, preventing it from drying out and becoming unworkable. Additionally, the water pump also serves to clean the concrete pump system after use. It flushes out any excess concrete residue or debris that may have accumulated inside the pump, ensuring that it remains in good working condition. In summary, the function of a concrete pump water pump is to supply water for the mixing of concrete, maintain the desired consistency, and clean the concrete pump system.

- Q: How long do concrete pump hoses typically last?

- Concrete pump hoses typically last between 3 to 5 years, depending on factors such as usage frequency, maintenance, and the type of material being pumped.

- Q: Can I get spare parts for concrete pump wear plates and cutting rings?

- Yes, spare parts for concrete pump wear plates and cutting rings are typically available. They can be purchased from various suppliers and manufacturers specializing in construction equipment parts.

Send your message to us

Tungsten Carbide PM200 Spectacle Wear Plate and Cutting Ring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords