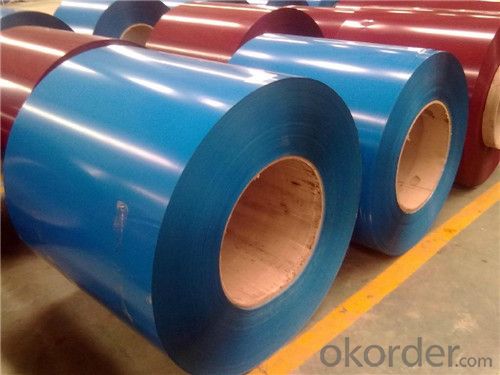

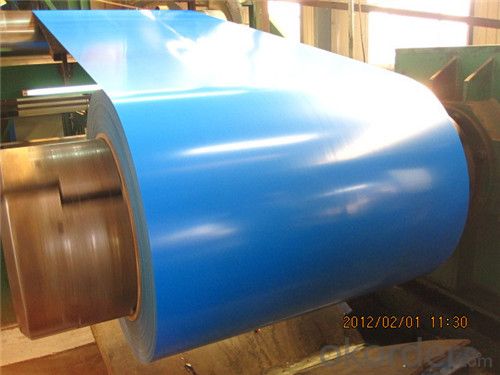

Z44 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z44 BMP Prepainted Rolled Steel Coil for Construction

Description of Z44 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z44 BMP Prepainted Rolled Steel Coil for Construction

SGCC, DX51D, ASTMA653, commercial quality, cs type A, locking forming type, S250, S280GD, S350GD, G550, SGC400, SGC440, S250GD, S350GD, G550, SGH340, SGH440.

HDGI Manufacture

THICKNESS 0.15-5.0MM, WIDTH, 914, 925, 1000, 1219, 1220, 1250, 1500, Galvanized steel coil, HDGI

Thick: 0.15 to 5.0mm

Reference standard: JIS G3302-1998, EN10142-2000, GB/T2518-2004, ASTM A653M

Zinc coating: Z60-Z300, G30-G90,

Regular Spangle, No-spangle or Mini Spangle

Applications of Z39 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z44 BMP Prepainted Rolled Steel Coil for Construction

Product | Z44 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z44 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel processing techniques for coils?

- There are several different types of steel processing techniques for coils, including hot rolling, cold rolling, galvanizing, and annealing.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment as they are typically shaped and welded to create various components such as pipes, tanks, and pressure vessels. These coils provide a strong and durable foundation for the equipment, ensuring it can withstand the harsh conditions and high pressures associated with oil and gas extraction and processing.

- Q: What are the different types of steel processing equipment for coils?

- There are several types of steel processing equipment for coils, including slitters, cut-to-length lines, leveling machines, coil cars, and stackers. Slitters are used to cut wide coils into narrower strips, while cut-to-length lines can cut coils into specific lengths. Leveling machines are used to flatten and remove any imperfections on the surface of the coils. Coil cars are used to transport the coils within the processing facility, and stackers are used to neatly stack the coils for storage or transportation.

- Q: What are the different types of steel coil treatments?

- There are several types of steel coil treatments, including pickling, oiling, and galvanizing. Pickling involves immersing the steel coil in an acid bath to remove impurities and scale, resulting in a clean surface. Oiling is the process of applying a thin film of oil to the coil to prevent corrosion during storage and transportation. Galvanizing is a treatment where a layer of zinc is applied to the steel coil, providing excellent protection against corrosion.

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- It sure will. It will also be a major pain in the back side to move it to where you can safely shoot at it.

- Q: What are the benefits of using stainless steel coils?

- There are several benefits to using stainless steel coils in various applications. Firstly, stainless steel coils are known for their exceptional strength and durability. This makes them highly resistant to corrosion, rust, and stains. As a result, stainless steel coils can withstand harsh environmental conditions and are suitable for both indoor and outdoor use. This longevity ensures that the coils will last for a long time, reducing the need for frequent replacements and saving costs in the long run. Additionally, stainless steel coils offer excellent heat resistance. They can withstand high temperatures without warping or losing their structural integrity. This makes stainless steel coils ideal for use in applications that involve extreme heat or thermal cycling, such as in industrial furnaces or heating systems. Another advantage of using stainless steel coils is their versatility. Stainless steel is a highly adaptable material that can be easily formed into various shapes and sizes. This allows for customization and flexibility in design, making it suitable for a wide range of applications in different industries. Whether it is used in construction, automotive, aerospace, or even household appliances, stainless steel coils can be tailored to meet specific requirements. In addition to their physical properties, stainless steel coils are also favored for their hygienic properties. Stainless steel is non-porous, which means it is resistant to bacteria, mold, and other contaminants. This makes it an excellent choice for applications that require strict cleanliness and hygiene standards, such as in the food and beverage industry or medical equipment. Lastly, stainless steel coils are also environmentally friendly. They are fully recyclable, meaning they can be melted down and reused to create new products. This helps to reduce waste and conserve resources, making stainless steel coils a sustainable choice for many industries. Overall, the benefits of using stainless steel coils include their strength, durability, heat resistance, versatility, hygiene, and environmental friendliness. These qualities make stainless steel coils a reliable and cost-effective solution for a wide range of applications.

- Q: I know that mild steel is more brittle than cast iron....but that is all.......please help??Thank you in advance......Ruby:D

- I know that mild steel is more brittle than cast iron You know wrong - cast iron is very brittle and mild steel is easy to bend and work. Cast iron is a high carbon product while mild steel is much lower carbon

- Q: Galvanized Steel or Standard Steel. This will be for the grilling surface.

- Bare steel. Galvanized or ANY coated racks will produce deadly chemicals in the food when heated. Galvanizing is a tin coating applied to the surface of the iron. Cadmium is a deadly chemical when ingested and is one of the chemicals on refrigerator racks. I'm not sure about Stainless Steel. The safest way is if in doubt DON'T.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: What are the different coil winding methods used for steel coils?

- The different coil winding methods used for steel coils include cross-winding, helical winding, and layer winding. Cross-winding involves winding the steel coil in a crisscross pattern to ensure even distribution of the material. Helical winding involves winding the steel coil in a spiral pattern, which provides strength and stability to the coil. Layer winding involves winding the steel coil in layers, with each layer placed on top of the previous one, ensuring efficient use of space and easy unwinding of the coil.

Send your message to us

Z44 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords