Z51 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

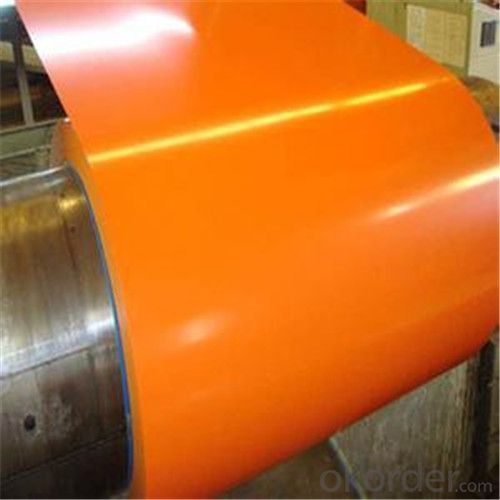

Structure of Z51 BMP Prepainted Rolled Steel Coil for Construction

Description of Z51 BMP Prepainted Rolled Steel Coil for Construction

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z51 BMP Prepainted Rolled Steel Coil for Construction

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3. Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle East, the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Applications of Z51 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z51 BMP Prepainted Rolled Steel Coil for Construction

Product | Z51 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z51 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

· ISO System. SGS and BV from third party.

· Finished Product Inventory-More Than 50000 Tons.

· Raw Material inventory -Over 80000 Mertic Tons.

· Shipment of stainless steel coil -More than 50 countries worldwide.

· We have the most convenient transport and prompt delivery.

· We offer competitive price with best service.

· We have high technical production line with top quality products.

· We have win high reputation based on best quality products.

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- In order to prevent rusting in the process of storage or transportation of steel roll, steel mills generally take the following packing: inner gas antirust paper wrapped with tape wrapped in plastic film sealing, intermediate, involute cardboard seal lining, cardboard corner, with iron and steel outer package corner protector, strapping fixed. If the inner package seal, so the steel coil is sank into the water, will not rust out.

- Q: How are steel coils used in the production of metal enclosures?

- Steel coils are used in the production of metal enclosures as they provide the raw material needed for forming and shaping the enclosure. The steel coils are processed and cut into sheets or strips, which are then bent, welded, or stamped to create the desired shape and structure of the enclosure. These steel sheets offer strength, durability, and a smooth surface finish to the final product, making them ideal for manufacturing metal enclosures used in various industries such as automotive, electronics, and construction.

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- You can indeed by using the correct flux as normal soldering fluxes as used by plumbers will not work. I believe to solder steel it requires an acid flux which will corrode copper so when its done make sure its well cleaned afterwards and if possible apply a corrosion proofer afterwards ie paint or even petroleum jelly. I am curious as to why you would want to solder wire to a steel nail.

- Q: I want to get a new knife but i cant decide if i wan a spyderco pacific salt or a cold steel ak47

- Hibben are even better in my opinion, but cold steel are reputable and do good quality high carbon steel knives and swords. Paul Chen does some knives and they are the best I've seen but a lot more expensive

- Q: How are steel coils used in the manufacturing of agricultural silos?

- Steel coils are used in the manufacturing of agricultural silos to create the cylindrical structure of the silo. These coils are rolled and shaped into large, seamless rings that form the walls of the silo. The coils provide strength and durability to withstand the weight of the stored grain or other agricultural products, ensuring the structural integrity of the silo.

- Q: i mean cor ten steel( rusted)

- Bill summed it up pretty quick and provided a link. For some reason you are focusing on the copper content when it really is insignificant in the overall picture of the sun hitting its surface. If you could elaborate more, maybe we could offer a better answer.

- Q: What are the different types of steel finishes available for coils?

- There are several types of steel finishes available for coils, including hot-dip galvanized, galvannealed, electro-galvanized, and painted finishes.

- Q: This question is directed to anyone who has played or know someone who plays a lap or pedal steel guitar.I've been a guitarist for about 8 years now and have played a variety of styles from rock, fingerstyle/classical, singer/songwriter acoustic stuff, ect, and now I've really had an interest in learning how to play a lap steel or pedal steel guitar. I am completely new to the instrument(s), so I'm seeking all the information I can. I do know that a pedal steel is a lot more expensive, so I'm probably looking to start on a lap steel for now. Basically how should I get started? Should I find a cheap lap steel at a pawn shop or purchase something new? Are there any good method books out there? I'm a pretty experienced guitarist, so should I expect to get the hang of it quickly? Is there much of a market for a lap/pedal steel player? haha.Also, I am left handed. How much trouble would it be to re-string a steel guitar? Or would I be better off getting a left-handed model?

- Hi, okorder /

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with zinc-nickel alloy.

- Q: mass of steel ball=66.80 gramsdiameter of steel ball=2.51 cm

- To calculate the density of any object you will always use the formula: Density = Mass / Volume (P=M/V). You have recorded the known values of the mass and the diameter of the ball (sphere), so we have everything needed to calculate the Density. Mass is 66.80g, but we shall need to use another formula to calculate the volume of the sphere. The formula to use is 4/3 X Pi X radius cubed. However, first of all we need to turn your measurement of the diameter of the steel sphere into the radius of the steel sphere (So that it can be substituted in place of the “radius” in the above formula). Simply half the diameter to find the radius. So 2.51 cm divided by 2 is 1.255 cm. Now insert the radius 1.255cm into the above formula. It would be read like this: 4/3 X 3.14159… X 1.255 ?cubed (OR 4/3 X 3.14159 X 1.255X1.255X1.255), = 8.2798. So, now we know that the sphere has a volume of 8.2798 cm cubed, we can use this number in place of the “V” in the density formula P=M/V, and we can also substitute in the Mass (66.80g). So now P=66.80 / 8.2798, which = 8.07g/cm cubed. Now we know that from your measurements, steel has a density of 8.07g/cm cubed! This is fairly close to the real life average density, which if I remember correctly is around 7.8 g/cm cubed. Just remember, though, that as steel is an alloy it’s density is not standard and varies due to carbon content etc. Anyway, I hope that helped you!

Send your message to us

Z51 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords