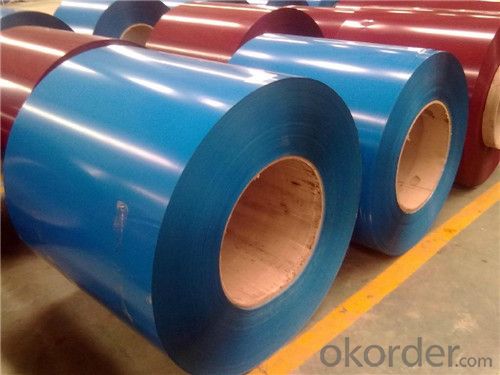

Z43 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z43 BMP Prepainted Rolled Steel Coil for Construction

Description of Z43 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z43 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z43 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z43 BMP Prepainted Rolled Steel Coil for Construction

Product | Z43 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z43 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the production of HVAC ductwork?

- Steel coils are used in the production of HVAC ductwork as they are rolled into thin sheets and then formed into the desired shape to create the ducts. The coils provide strength and durability to the ductwork, ensuring it can withstand the high temperatures and pressure of air conditioning and heating systems.

- Q: How are steel coils used in the production of agricultural structures?

- Steel coils are widely used in the production of agricultural structures due to their exceptional strength and durability. These coils, typically made of high-quality steel, are used in various applications throughout the agricultural industry. One of the primary uses of steel coils in agricultural structures is for the construction of buildings and storage facilities. Steel coils are used to create sturdy frameworks, supporting the walls and roof of these structures. The inherent strength of steel allows for the construction of large, open spaces without the need for excessive support columns, providing farmers with ample space to store their crops, machinery, and livestock. Additionally, steel coils are utilized in the manufacturing of agricultural equipment and machinery. Whether it is tractors, plows, harvesters, or irrigation systems, steel coils play a crucial role in the fabrication of these tools. The high tensile strength of steel ensures that these agricultural machines can withstand the demanding conditions of farming, such as heavy loads, rough terrains, and exposure to harsh weather elements. Furthermore, steel coils are also used in the production of fencing and enclosures for agricultural purposes. Whether it is to protect crops from animals or to create boundaries for livestock, steel coils are an essential component in constructing sturdy and reliable fences. The strength of steel ensures that these fences can withstand the pressure from animals, preventing them from breaking through and causing damage to the crops or escaping. In summary, steel coils are integral to the production of agricultural structures and equipment. Their strength, durability, and versatility make them an ideal material for constructing buildings, manufacturing machinery, and creating fences in the agricultural industry.

- Q: How are steel coils tested for quality?

- Steel coils are tested for quality through a series of rigorous inspections and tests. These include visual inspections to identify any surface defects, dimensional measurements to ensure proper size and shape, and mechanical tests such as tensile strength and hardness tests. Additionally, non-destructive testing methods like ultrasonic testing and magnetic particle inspection are used to detect internal defects or cracks. These comprehensive quality checks ensure that steel coils meet the required standards and are fit for their intended applications.

- Q: What are the main factors that affect the quality of steel coils?

- The main factors that affect the quality of steel coils include the composition and purity of the steel used, the manufacturing process and techniques employed, the level of heat treatment and cooling, the presence of any impurities or defects, and the overall handling and storage conditions.

- Q: How do steel coils contribute to the energy infrastructure sector?

- Steel coils contribute to the energy infrastructure sector by serving as a crucial component in the construction and maintenance of power plants, oil and gas pipelines, and electrical transmission systems. These coils are used to manufacture various equipment and structures, such as turbines, generators, transformers, and transmission towers. Additionally, steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the energy infrastructure, ultimately supporting the efficient and uninterrupted supply of electricity, oil, and gas to meet the growing energy demands.

- Q: I'm trying to put together a small structure using galvanized steel electrical conduit (3/4) and I can't seem to find a T-junction conduit coupler anywhere. I'm wondering if I could weld the tubing together, but I'm not sure if I can weld galvanized steel. Also, if I can weld them, is there any special technique that I need to use outside of regular acetelene/oxygen torch and solder?

- Conduit is made from low carbon steel. Then the galvanized coating is applied. The fumes from the coating are poisonous when heated. So your choices are to remove the coating then do your heating. They can be soldered, brazed and welded. It all depends how strong you want the joint and how high a temperature used. If you use silver solder the joint must be very tight. If you use lead solder a flux must be used same as brazing. Welding is the strongest and the melting temperature of steel is about 2600 degrees.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- Titanium Industrial Barbell

- Q: ex: boat hull made out of steel

- Well our boat hulls have two types or primer, Red Lead, or a yellow colored paint I think it was zinc-chromate. And then, numerous coats of the grey (Navy) paint. US Navy, ABE5, USS Enterprise

- Q: would you consider steel a flexible substance...i am debating this with my coworkers.Thanks,

- Steel is a flexible material. It can be deformed and return to it's original shape up while the stress applied is still in the elastic range. How flexible depends on size, shape, and alloy. Some alloys are more flexible than others and a lot of this is controlled by carbon content.

- Q: What are the different types of steel grades used for coil production?

- There are various types of steel grades used for coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These grades are selected based on the specific requirements and application of the coils, such as strength, corrosion resistance, and formability.

Send your message to us

Z43 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords