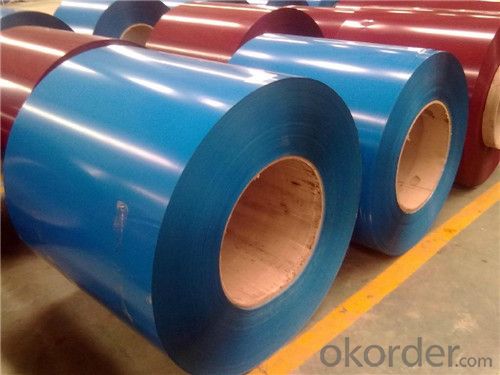

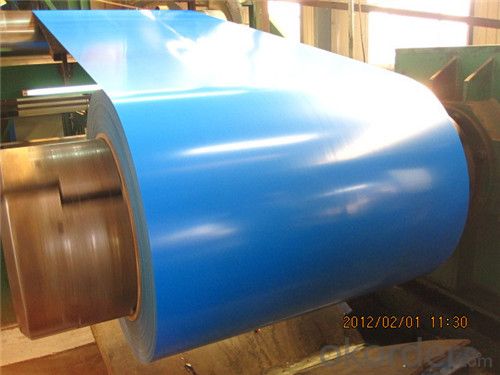

Z41 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z41 BMP Prepainted Rolled Steel Coil for Construction

Description of Z41 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Main Feature of Z41 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z41 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z41 BMP Prepainted Rolled Steel Coil for Construction

Product | Z41 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z41 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- From what I understand m390 is a new steel (at least for benchmade) so there doesn't seem to be a consensus on how it performs. Looking at the table, it should be very corrosion resistant. I'd guess it could be classified as a stainless steel. Sorry I don't have more info for you. EDIT: here's a link from the steel manufacturer. I hope this info helps.

- Q: hey i was looking to buy a khukuri machete by cas iberia. its made of carbon steel but doesnt say which one. anyone that is into knives and all that know how this would hold up and the rust resistance of it? mostly be used for cutting bush and small trees

- There's no way to tell from the information you posted. Given it's for a machete I would guess it would be a fairly high carbon steel. Rust resistance will be relatively poor. It will last for years though as long as you clean and dry it after use.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger -- Mostly because it was a rousing, entertaining, old-school adventure film, plus it was true to the character of Steve Rogers/Captain America. Man of Steel, IMO, had a poor script, tinkered way too much with one of the great superhero origin stories and was not at all true to the character. Historically Superman has always been a symbol of heroism, proud, strong, beaming. But what we got in that movie was an utterly cheerless, dour automaton devoid of any kind of charisma or presence. I don't know who that boring, depressed dude who looked like Superman was in that movie, but he most certainly wasn't Superman.

- Q: How are steel coils used in the production of automotive parts?

- Steel coils are used in the production of automotive parts as they serve as the primary raw material for manufacturing various components such as body panels, chassis, and structural parts. These coils are processed through different techniques like cutting, stamping, and welding to shape and form the desired parts. The strength and durability of steel make it an ideal material for automotive applications, ensuring the safety and performance of vehicles.

- Q: How are steel coils cut to size?

- Steel coils are cut to size using a variety of methods such as shearing, slitting, or laser cutting. These processes involve using specialized machinery to ensure precise and accurate cuts according to the required dimensions.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- Steel muscles is very nice, but working on your contractions is a longer lasting necessity. In my opinion.

- Q: How are steel coils used in the production of wind turbines?

- Steel coils are used in the production of wind turbines to manufacture the tower, nacelle, and other structural components. The coils are processed and shaped into various parts, ensuring the turbines have a sturdy and durable construction. Additionally, steel coils are employed in the manufacturing of the turbine blades, providing strength and reliability to withstand the forces of wind.

- Q: What are the different types of steel coil edge treatments?

- There are several different types of steel coil edge treatments used in the manufacturing and processing of steel coils. These treatments are done to enhance the edge quality, protect against damage, and facilitate handling and processing of the coils. Some of the common types of steel coil edge treatments include: 1. Mill Edge: This is the standard edge treatment provided by the steel mill. It is the raw edge of the steel coil that has been produced during the hot rolling process. Mill edge is typically sharp and may have some irregularities. 2. Slit Edge: Slit edge is a type of edge treatment where the coil is slit to the desired width, and the edges are then processed to remove any burrs or unevenness. Slit edge coils have smoother edges compared to mill edge coils. 3. Deburred Edge: Deburring is a process that removes any sharp or rough edges from the coil. It is done using specialized equipment or techniques to create a smoother and safer edge. Deburred edges are commonly used in applications where safety and handling are critical. 4. Rounded Edge: Rounded edge treatment involves rounding the edges of the coil to reduce the risk of damage during handling and processing. This treatment is often used in applications where the coil needs to be uncoiled or fed into machinery without causing any damage. 5. Beveled Edge: Beveling is a process where the edges of the coil are chamfered or cut at an angle. Beveled edges are used in applications where easy insertion, joining, or welding of the coil is required. The beveling process also helps to improve the strength and durability of the edge. 6. Sheared Edge: Shearing is a cutting process where the coil is cut to the desired width using high-pressure blades or scissors. Sheared edge treatment provides a clean and straight edge, free from burrs or irregularities. It is commonly used in applications where precise dimensions and a smooth edge are required. These are just a few of the different types of steel coil edge treatments commonly used in the industry. The choice of edge treatment depends on the specific requirements of the application, such as handling, processing, safety, and aesthetics.

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- titanium is a light-weight silvery metallic element that is corrosion-resistant while a stainless steel is a steel containing atleast 12 % chromium and is also corrosion-resistant. both are good choices for a new exhaust.

Send your message to us

Z41 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords