Geotextile Bidim 4190g Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

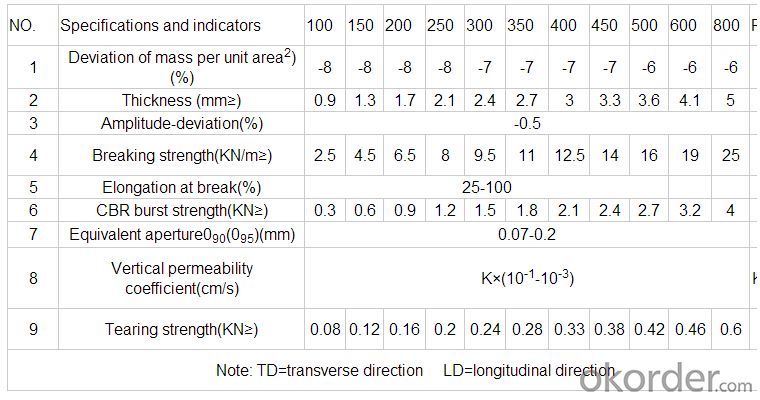

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are designed to provide strength, stability, and filtration in various applications, including landfill construction. They can be used as a reinforcement layer in landfill liners or caps to enhance the stability and prevent erosion of the waste containment system.

- Q: Can geotextiles be used in the protection of shoreline structures?

- Yes, geotextiles can be used in the protection of shoreline structures. Geotextiles are permeable fabrics that can be placed to prevent erosion and stabilize the shoreline. They can be used as a barrier between the soil and water to prevent soil loss and maintain the integrity of shoreline structures.

- Q: How do geotextiles help with reinforcement of geosynthetic tubes?

- Geotextiles help with the reinforcement of geosynthetic tubes by providing additional strength and stability to the structure. They act as a barrier between the soil and the tube, preventing soil intrusion and enhancing the tube's durability. Geotextiles also distribute the load more evenly, reducing the stress on the tube and preventing deformation or failure.

- Q: Polyester geotextile price how much

- Is there a scientific name? Added: Will not it be filament geotext? This is what we have, but the scientific name does not call you this!

- Q: Can the roof waterproof with geotextiles?

- According to personal circumstances, but suggested to find professional personnel assessment. First of all, professional construction, roof waterproofing is a very test of professional skills work, need to hold the local construction administrative departments issued the job certificate. Professional construction units will be detailed survey and roofing drawings. Survey the actual situation of statistics, regional climate, housing and other factors, with the data obtained to develop professional construction program. Construction will be the future may cause housing flaws in the defect to be repaired, so to prevent the future. Secondly, qualified materials, roof leakage in China, about 20% of the material is unqualified, resulting in leakage of the roof of the situation. So in the choice of roof or roof of the material must meet the relevant national standards, and generally qualified roofing materials will have qualified documents and quality inspection departments of qualified certification. In the choice of decoration materials can request the relevant proof, at the same time to check the decoration materials production date, brand, batch number, specifications and so on information to ensure that the quality of qualified roofing materials. Finally, the acceptance of the project, because the roof or roof environment is very complex, so its decoration construction requirements must be strict. The process needs to have a waterproof, leak-proof, anti-seepage function, the summer high temperature can be high temperature, anti-ultraviolet, cold winter to have anti-freeze-resistant low temperature, daily sunshine to have anti-aging and so on.

- Q: Bought a roll of geotextiles soon run out, do not know if there is nothing to replace the geotextile material more

- I use a beverage bottle, the beverage bottle cut than the flower pot of the water hole in the above, you can tie some holes on the above.

- Q: 800g / m2 non-woven geotextile vertical permeability coefficient is generally how much

- 800g / m2 non-woven geotextile vertical permeability coefficient is: 6.1 × 10-2

- Q: What is the price of composite geotextile?

- Geotextile is divided into polyester short geotextile, staple acupuncture geotextile, polyester filament geotextile, woven geotextile, filament woven geotextile, and so on. Specifications and different models, the price is also different, composite geotextile weight in the 80-1500g / ㎡ between the quality standards are divided into non-standard, whitening A, Sinochem, the general national standard and so on. The t value is generally between 4900 and 7500 yuan / ton, 187 & lt; 6600 & lt; 5604

- Q: Can geotextiles be used in shoreline protection projects?

- Yes, geotextiles can be used in shoreline protection projects. Geotextiles are often utilized in coastal erosion control and shoreline stabilization efforts as they can help to prevent soil erosion, control sediment movement, and enhance the stability of shoreline structures.

Send your message to us

Geotextile Bidim 4190g Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords