FRP Honeycomb Sandwich Panels with Wooden PP Core

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard export package |

| Delivery Detail: | One week |

Specifications

honeycomb wood panel

1.LIGHT AND STRONG

2.WATER PROOF AND MOISTURE DAMPENING

3.ENERGY ABSORPTION,etc.

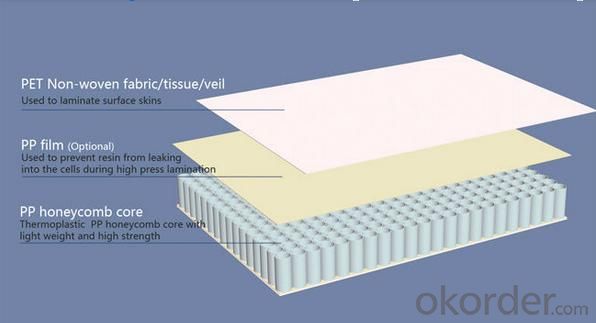

Wooden pp honeycomb sandwich panel

honeycomb wood panel : parameter

Items | Type A | Type B | Type C |

Color | White | White | White |

Cell core diameter(mm) | 8 | 10 | 12 |

Density( Kg/m3) | 80 | 75 | 70 |

Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

Modulus of compression(MPa) | 45.7 | 41.2 | 38.9 |

Shear Strength(MPa) | 0.5 | 0.45 | 0.4 |

Effective Temperature(°C) | -40 ~ +80 | -40 ~ +80 | -40 ~ +80 |

Thermal Insulation U-value(W/m2k) | 2.2 | 2.2 | 2.3 |

honeycomb wood panel : excellences

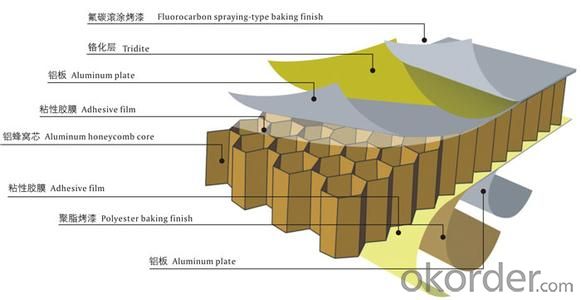

PP honeycomb as core material, wooden skin laminated on both sides, finished panel is very light and stiffness strength enough. It's one kind of newest advertisement and decoration panel.

| Light and strong | High compressive strength. High shear strength. Low density and Light weight. |

| Green and environmentally friendly | Energy saving. 100% Recyclable. |

| Water proof and moisture dampening | With the excellent ability of water proofing, HolyCore can be well applied in the over-water buildings. Corrosion resistant. Strong resistance to chemicals, seawater eroding. Sound isolation. Efficient in reducing the damping vibration and absorbing the noises. |

honeycomb wood panel : aplications

1. Construction - platform in scaffold, stadium bleachers, exhibitions and stages;

2. Ships and yachts - interior wall panels, roof, freezer, deck, etc;

3. Automobiles interior decorations, van body walls and so on;

4. Logistic Various kinds of boxes and containers.

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- If it is added foam cement insulation board, just add a bubble device, the principle of insulation is the air bubble to reduce heat conduction. Foam plastic cement insulation pedal brother Xi Jiadian tripod end plate is added EPS polystyrene foam, insulation principle is polystyrene foam to reduce heat conduction.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: General color steel foam sandwich panels. How much a square is flat

- Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement The outermost front panel is called a panel, and the back is called a backplane The inner board is called the core plate Ask the question? The They said that the use of the shoe cabinet, wardrobe with a sandwich panel answer:

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- The inner panel can be installed with conventional technology, pay attention to the edge, the installation of corners, as well as their installation with the wallboard order, part of the first to install

- Q: How does the wall rock wool sandwich panel be installed?

- will be fixed on the wall insulation material, play a warm and warm role in warm technology

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- In fact, you can also choose the ceiling, the effect of the ceiling may be better.

- Q: Color steel sandwich board on the price of how much?

- Due to the level of restrictions, there must be inappropriate, hope to add to the same channel or finger scaffolding erection of quality requirements and safety requirements should be organically unified to ensure that the erection process and the subsequent use and removal process of safety and application

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q: The stove is dedicated to the plastic used for plastic paper

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, maintenance-free features, has been widely used Caigang sandwich panels Is the current building materials in a common product, not only can be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor. The tile is used for the panel for the wall

Send your message to us

FRP Honeycomb Sandwich Panels with Wooden PP Core

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords